4. Use the lens removal tool to unscrew the top lock ring.

5. The lens is now exposed and can be carefully removed by holding it by the sides only. Set

the o-ring to the side. Use a clean rag or rubber gloves to carefully remove the lens. Avoid

touching the front and back surface of the lens. Check for any scratches, pits and blemishes.

The lens will have a yellowish color to it without any cracks or blemishes. It is very important

for the optics to be clean. If a lens has blemishes or damage, cleaning of the optic may not

repair the damage.

NOTE: The lens may appear clean in the assembly, but may still be dirty. The lens must be

taken out to check for cracks and blemishes.

To clean a lens:

1. Remove visible debris from the lens using a Q-tip soaked in isopropyl alcohol or rubbing

alcohol (90% alcohol based).

2. Flush the lens with 99% isopropyl alcohol.

3. Using a lens tissue soaked in isopropyl alcohol, wipe the optic lightly in a circular motion.

4. Repeat step 3 with a new lens tissue. The isopropyl alcohol dries very quickly. The surface of

the optic should be clean and spotless when cleaning is finished. If blemishes on the optic

will not clean off, a replacement optic should be purchased to achieve optimum laser cutting

and engraving performance.

To reinstall the lens after cleaning:

1. Carefully place the lens back in the optics assembly on top of the o-ring. The convex side of

the lens must be facing upwards as it is placed back in the optics assembly.

2. Screw the black lock ring back into the assembly using the lens tool.

3. Reinstall the optic assembly back into beam path tube.

4. Reconnect the air line, shroud and the HF sensor wire (if present).

NOTE: It is recommended to do a beam alignment through the nozzle after you reinstall the

lens.

Lead Screw Nut Adjustment

Please consult the factory before removing and cleaning the nut.

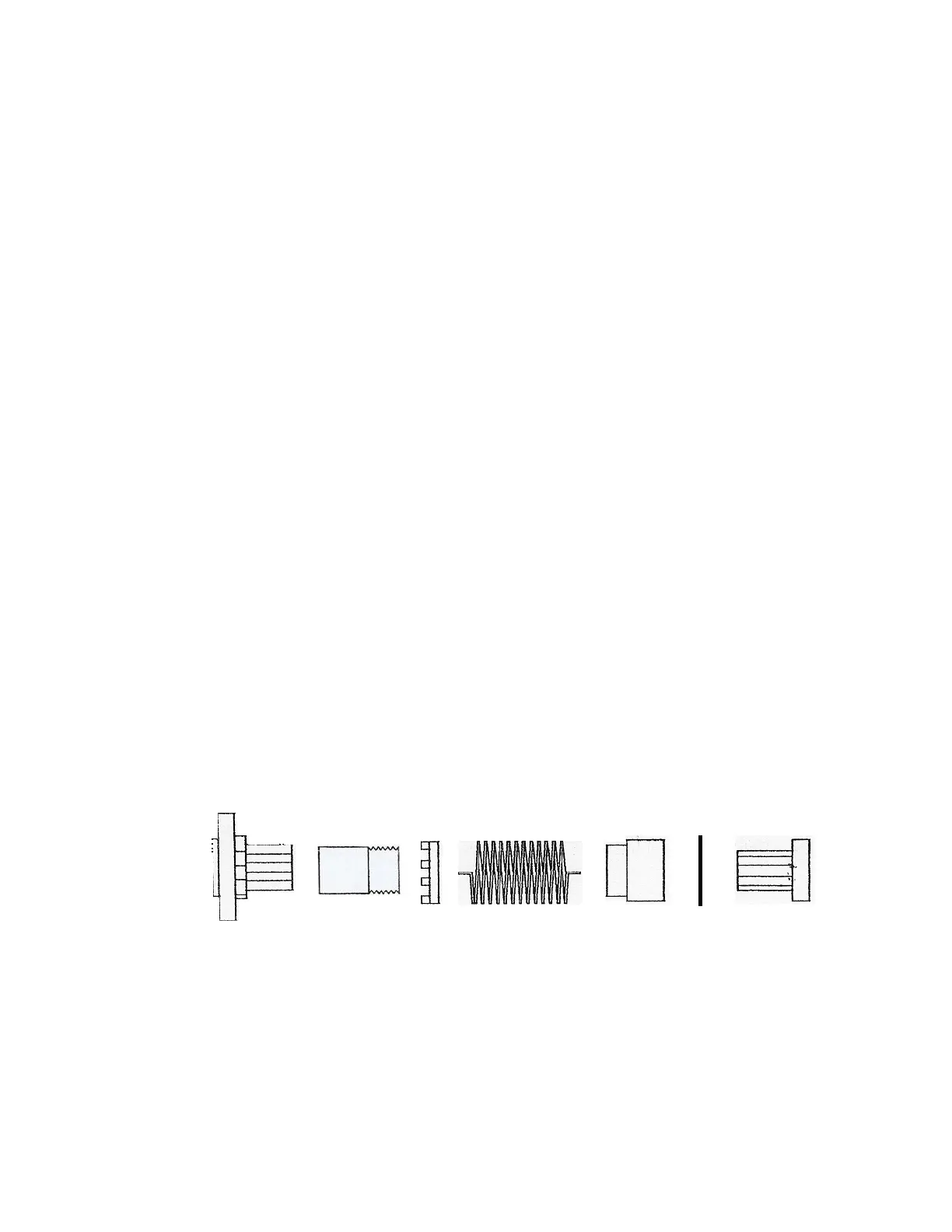

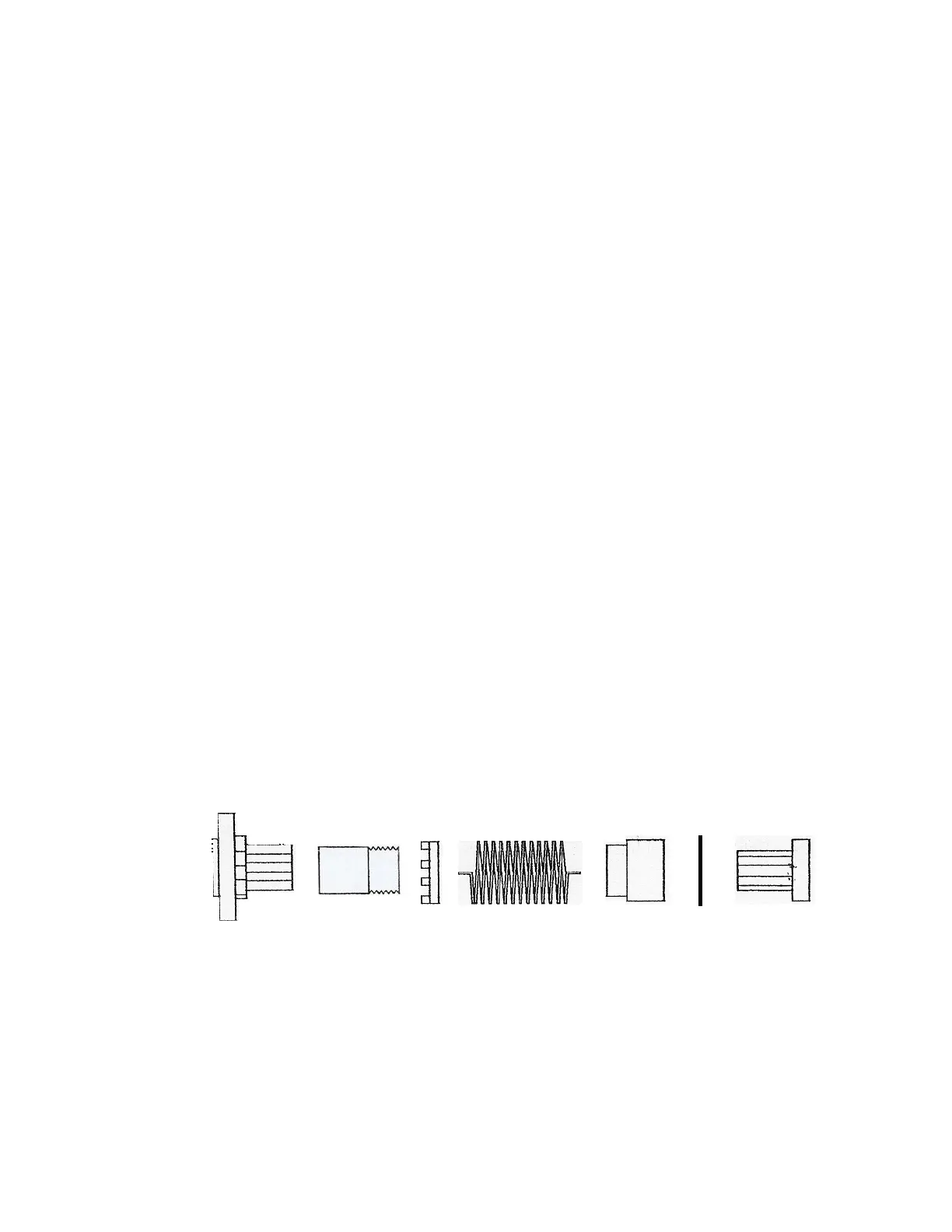

1 2 3 4 5 6 7

Lead Screw Nut Assembly

1. Mounting Body

2. Inner Body Spline

3. Spring Adjustment Collar

4. Spring

5. Spacer Nut

6. Rubber Washer

7. Rear Body

60

Loading...

Loading...