- 26 -

Workshop Manual KD 441_cod. 1.5302.865_2

nd

ed_ rev. 01.

4

33

34

32

35

1

A

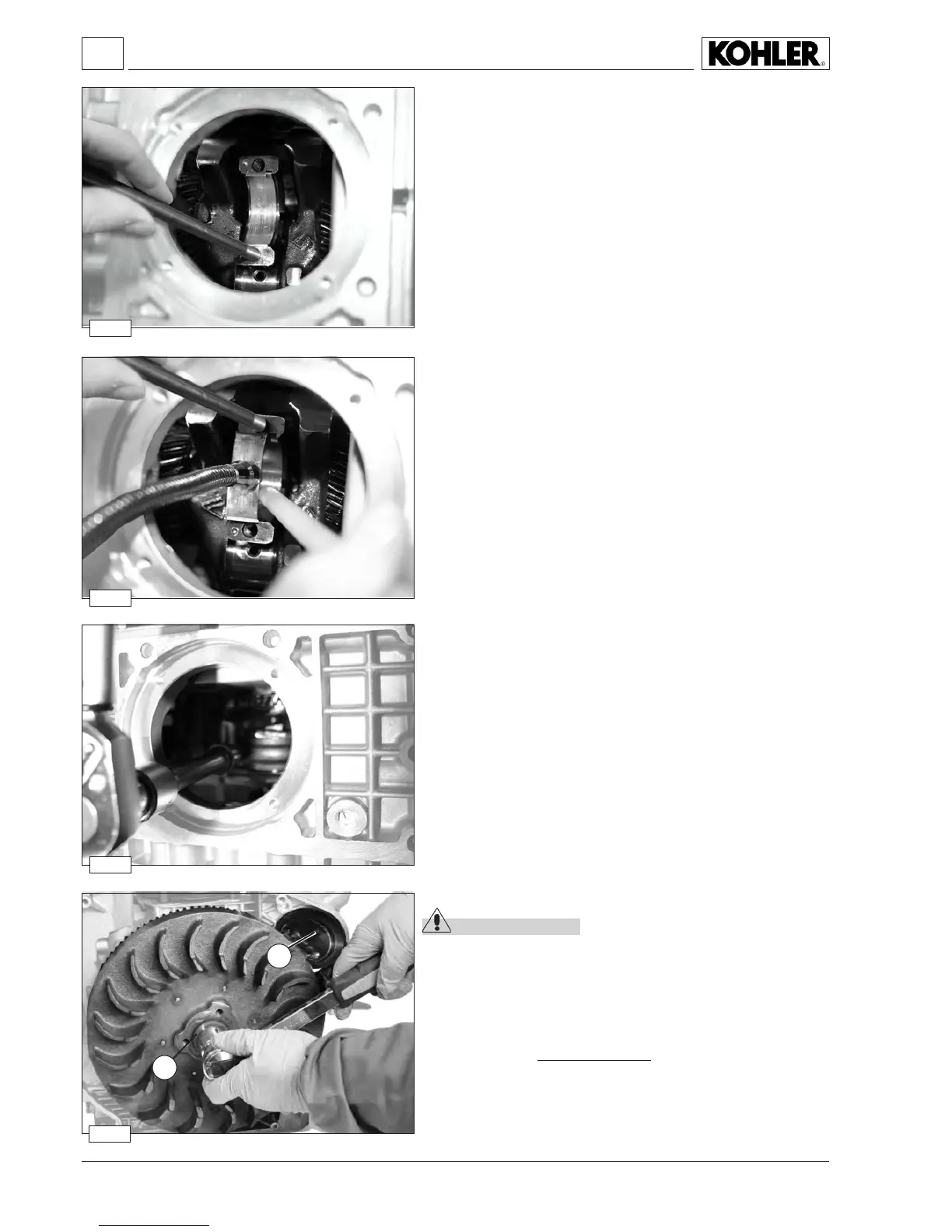

Disassembly

Flywheel

Danger – Attention

During the demounting phases, pay particular attention to pre-

vent the ywheel from dropping as this could seriously injure

the operator.

Wear protective goggles when removing the ywheel ring.

Remove the starting motor and assemble special tool A p/n 1460-330

initshousingtolocktherotationoftheywheel.

Unscrew bolt 1 in a clockwise direction.

Removetheywheelwithapullerp/n°1460-120.

Make sure that the tapered surface that couples to the drive shaft is

not damaged.

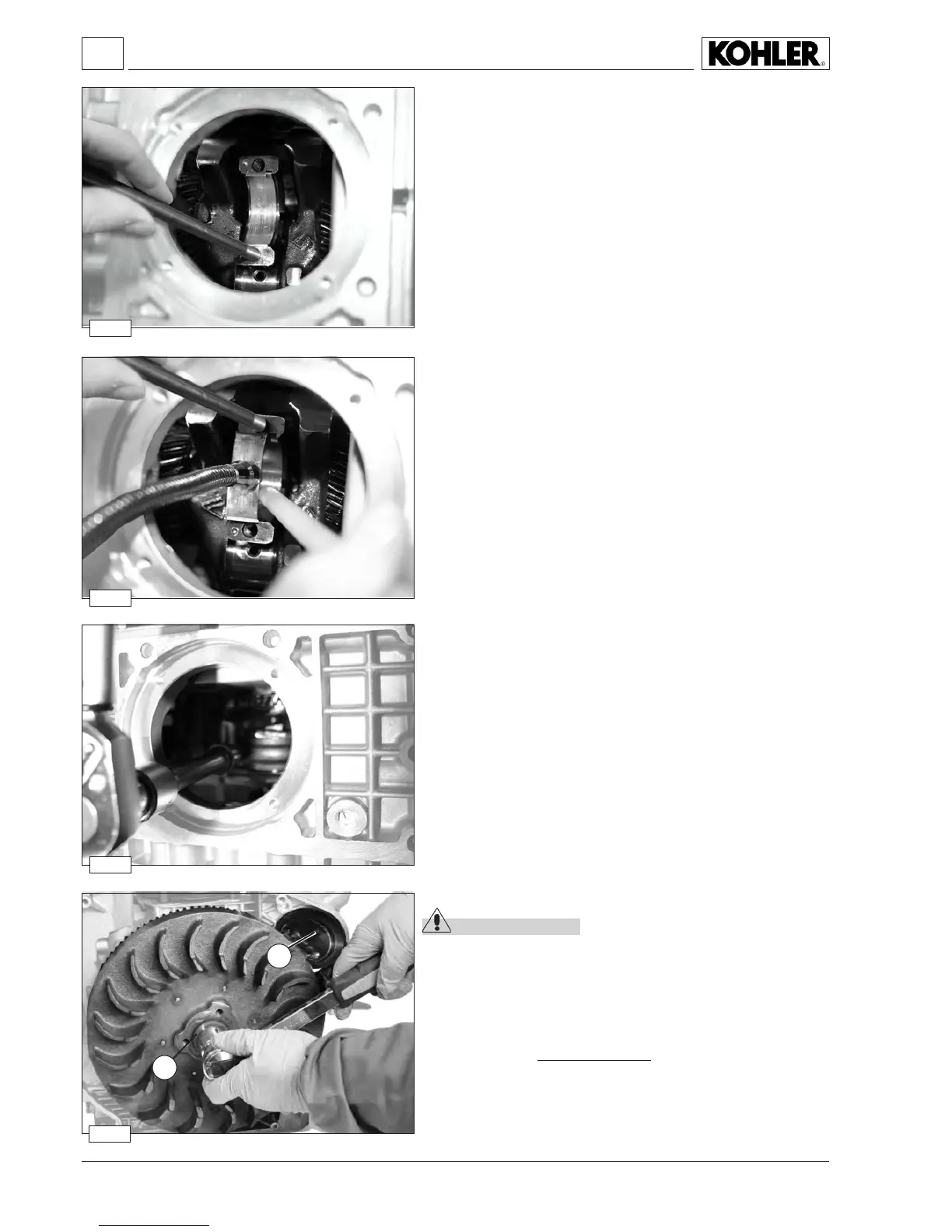

9- Pull the bar outwards so as to place the connecting rod shaft on

the crankshaft and make the upper connecting rod half bearing

accessible.

10

- Using the nylon bar, push on a half bearing side and disconnect it.

11

- Using a magnet, remove the half bearing, taking care not to make it

fall inside the engine.

12

- When reassembling, correctly place the half bearing in its seat. If

necessary, push it with a nylon bar to avoid damages.

13

- Generously lubricate the half bearing and the connecting rod pin.

14

- Push the connecting rod upwards using the bar of the special tool

to replace it in its seat on the connecting rod pin of the crankshaft.

15- Replace the half bearing of the connecting rod cap

16 -Reassemble the connecting rod cap after lubricating it generously.

17- Tighten the screws alternately to a torque of 35 Nm.

Loading...

Loading...