- 48 -

Workshop Manual KD 441_cod. 1.5302.865_2

nd

ed_ rev. 01.

102

1

101

103

6

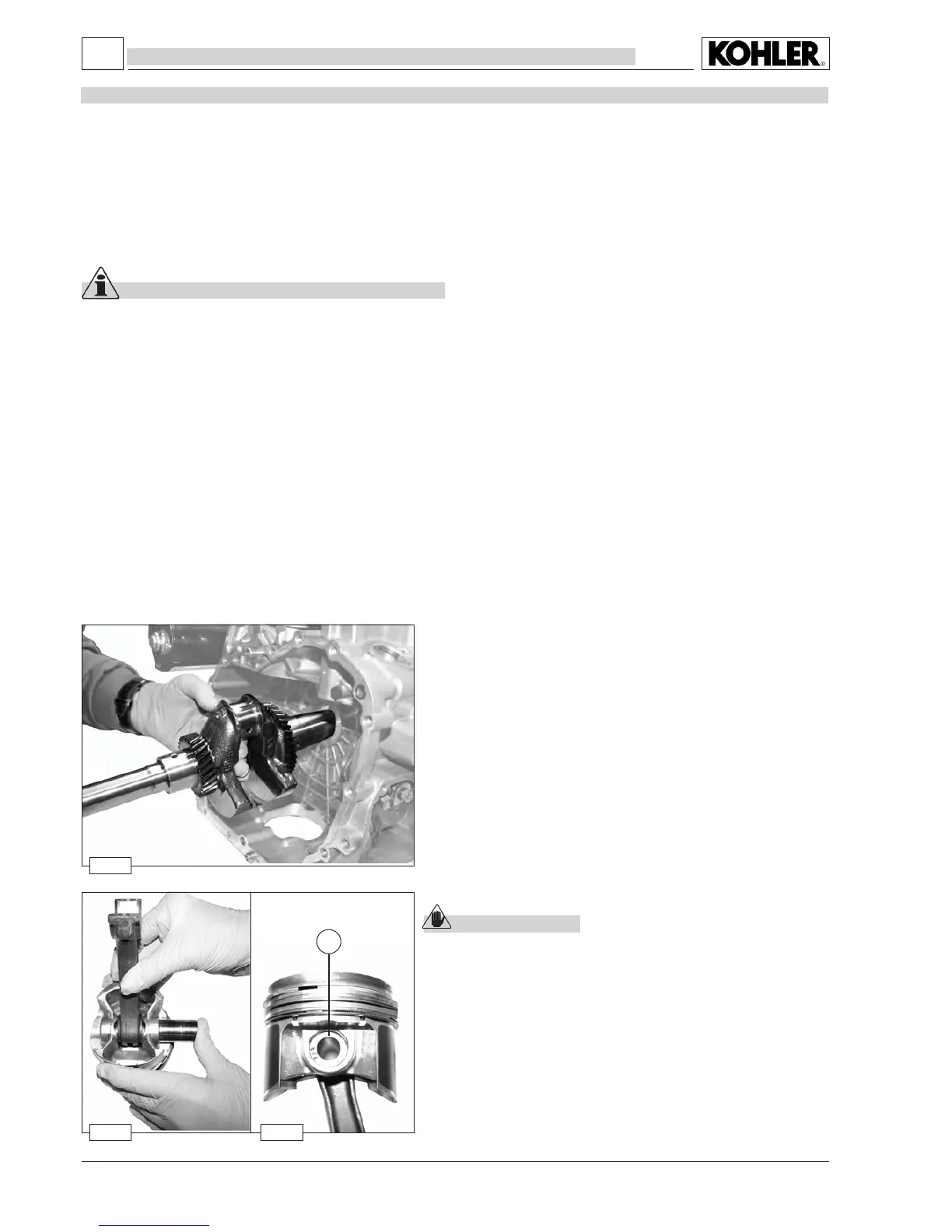

Piston

Caution – Warning

Lubricate the following parts with oil before mounting: the piston pin,

the piston, the cylinder and the big-end bearing

Connect piston to connecting rod, lubricate piston pin and introduce

it into the piston / connecting rod assembly by exerting pressure with

yourthumb(g.104).

Fit both piston pin circlips 1 and check that they are well seated.

– Information is given in a logical order in terms of timing and

sequence of operations.

The methods have been selected, tested and approved by

the manufacturer’s technical experts.

– This chapter describes procedures for installing assemblies

and/or individual components that have been checked,

overhauled or replaced with original spare parts.

Important

To locate specic topics, the reader should refer to the

index.

– The operator must wash, clean and dry components and

assemblies before installing them.

– The operator must make sure that the contact surfaces are

intact, lubricate the coupling parts and protect those that are

prone to oxidation.

RECOMMENDATIONS FOR REASSEMBLING

– Before any intervention, the operator should lay out all equi-

pment and tools in such a way as to enable him to carry out

operations correctly and safely.

– For safety and convenience, you are advised to place the

engine on a special rotating stand for engine overhauls.

– Before proceeding with operations, make sure that appro-

priate safety conditions are in place, in order to safeguard

the operator and any persons involved.

– Inordertoxassembliesand/orcomponentssecurely,the

operator must tighten the fastening parts in a criss-cross or

alternating pattern.

– Assemblies and/or components with a specic tightening

torque must initially be fastened at a level lower than the

assignedvalue,andthensubsequentlytightenedtothenal

torque.

REASSEMBLY

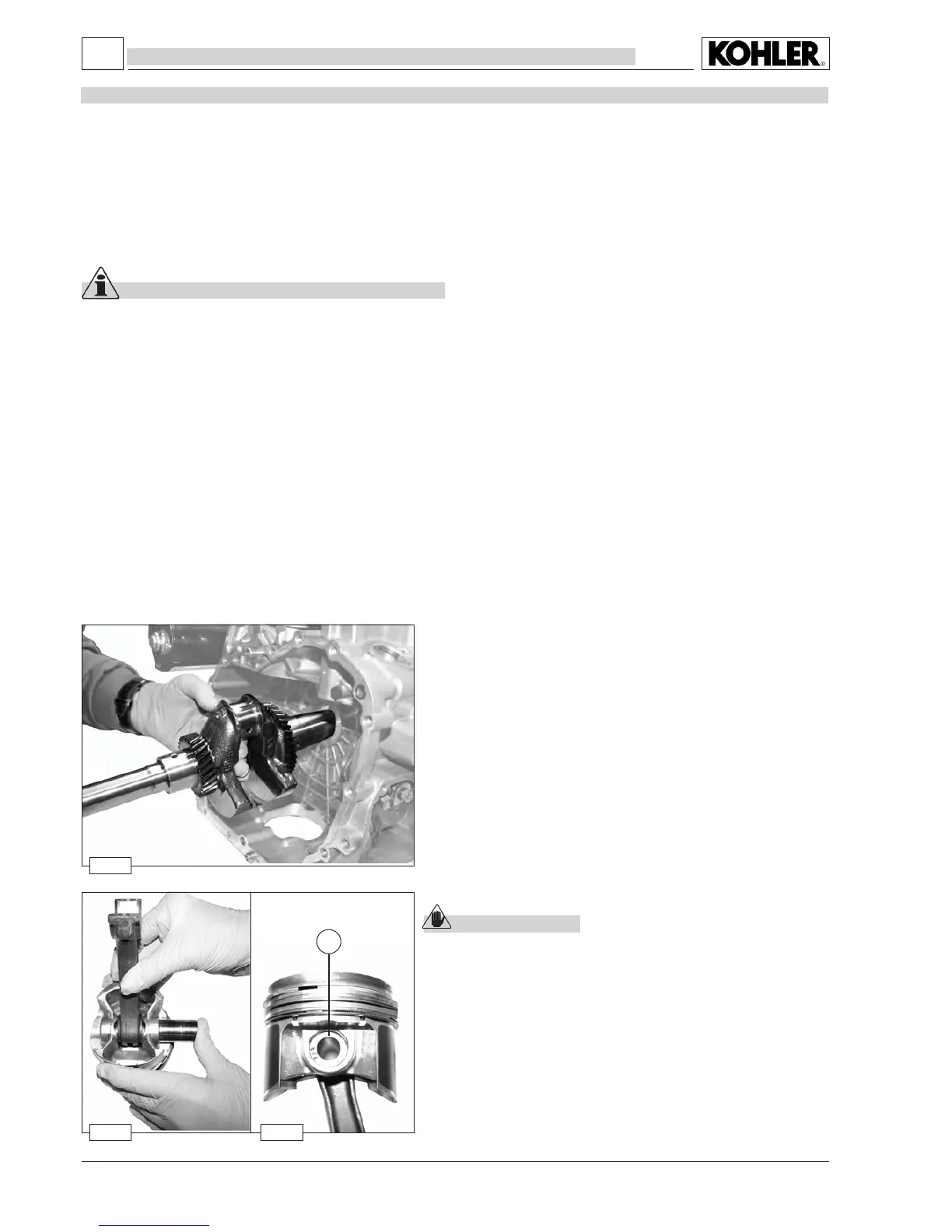

Crankshaft

After lubricating the crankshaft and the main bearing, insert the cran-

kshaftintothecrankcasesupport,asshowninthegure.

Loading...

Loading...