- 36 -

Workshop Manual KD 441_cod. 1.5302.865_2

nd

ed_ rev. 01.

62

C

1

63

64

65

5

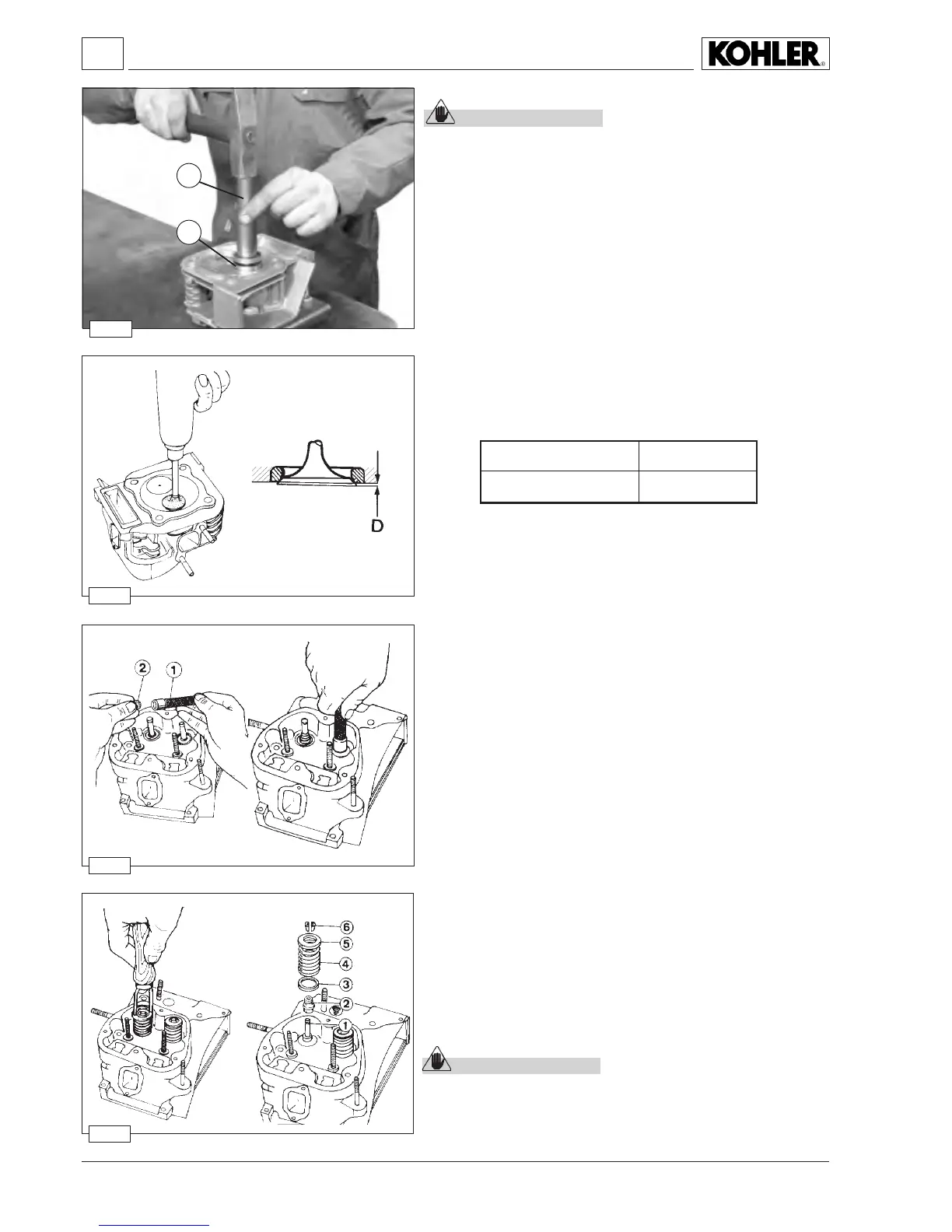

D 0.35÷0.65

1.5

Valve seat lapping

Aftercuttingvalveseats,lapvalveseatswithnelappingcompound.

wear limit

Valves - Oil seal in valve guide

To prevent seal 2 from being deformed when the valve guide is

mounted,titintotool1 p/n° 1460-047 after having thoroughly lubri-

cated it.

Firmly press to insert the oil seal in the seat on the valve guide to its

limit stop.

Valves - Reassembly

Components:

1 Valve stem

2 Oil seal

3 Spring washer/set

4 Spring

5 Cap

6 Half collets

Caution – Warning

To reassembly half collets place a suitable plate under the valve

head and press down rmly as indicated in the gure.

Check that the half collets are correctly attached to the valve.

Overhauls and checking

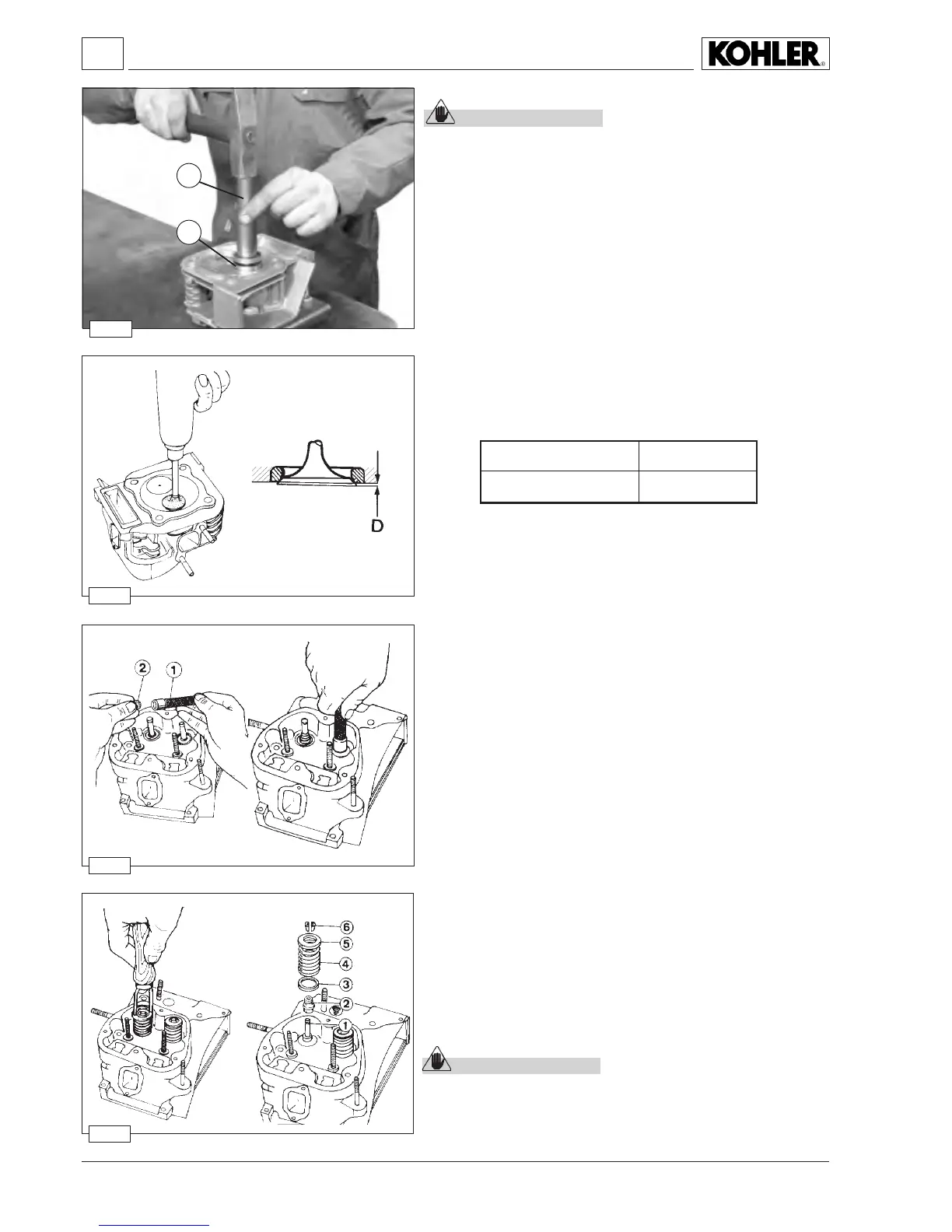

Valve seats - Reassembly

Caution – Warning

Thoroughly wash the cylinder head and the valve seats before

reassembly.

Place valve seat 1 onto its seat.

Place the driving tool for valve seat C on the valve seat.

Drive the seat in by hammering on tool C until the seat is inserted in

its housing to its limit stop.

Repeat these operations for valve seat 2 using the tool B.

Loading...

Loading...