- 49 -

Workshop Manual KD 441_cod. 1.5302.865_2

nd

ed_ rev. 01.

104

6

105

106

A

B

C

107

B

B

A

A

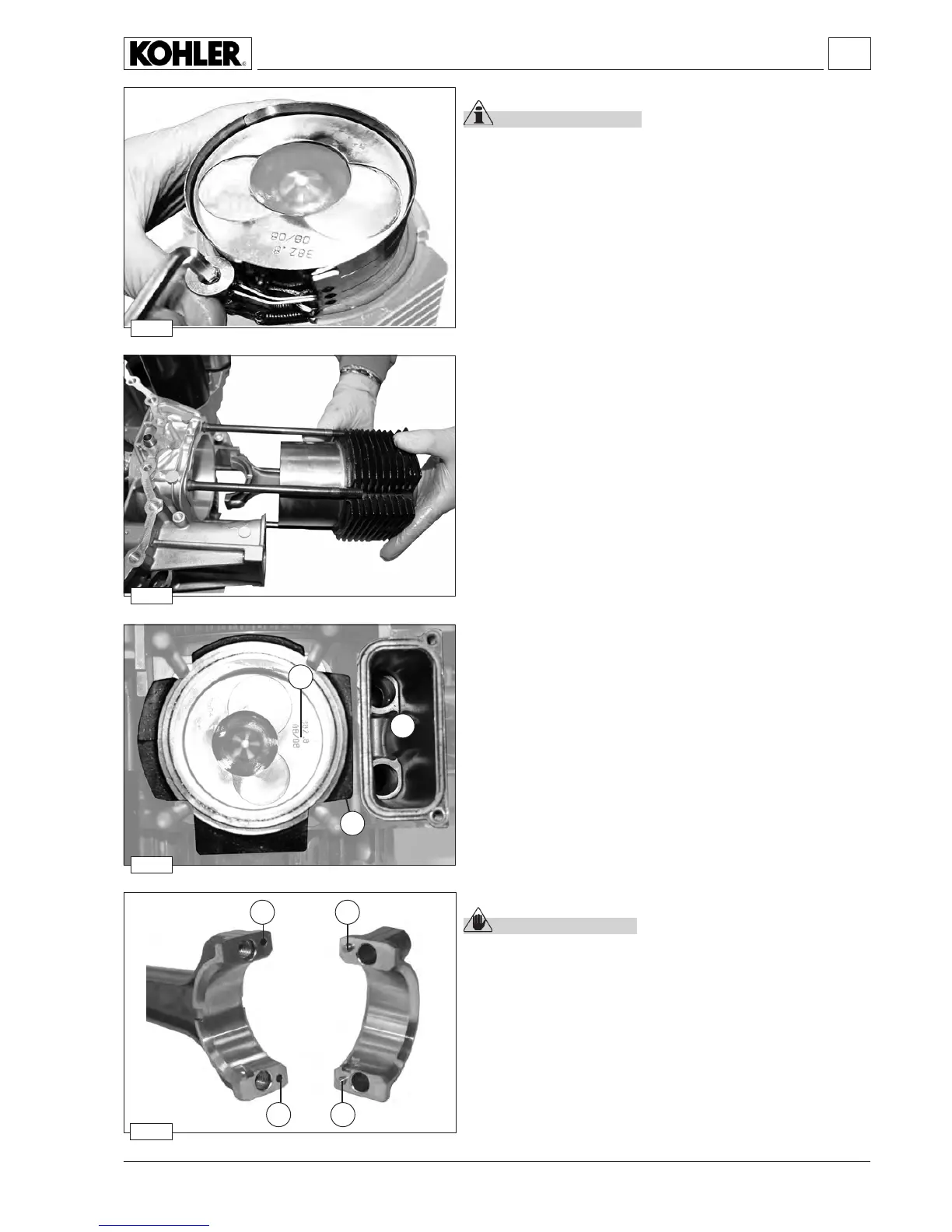

Reassembly

Cylinder

After lubricating the connecting rod big end bearing, insert the cylin-

der, piston and connecting rod assembly from its seat into the cran-

kcase, taking care the cylinder keeps its correct position, as shown in

gure106.

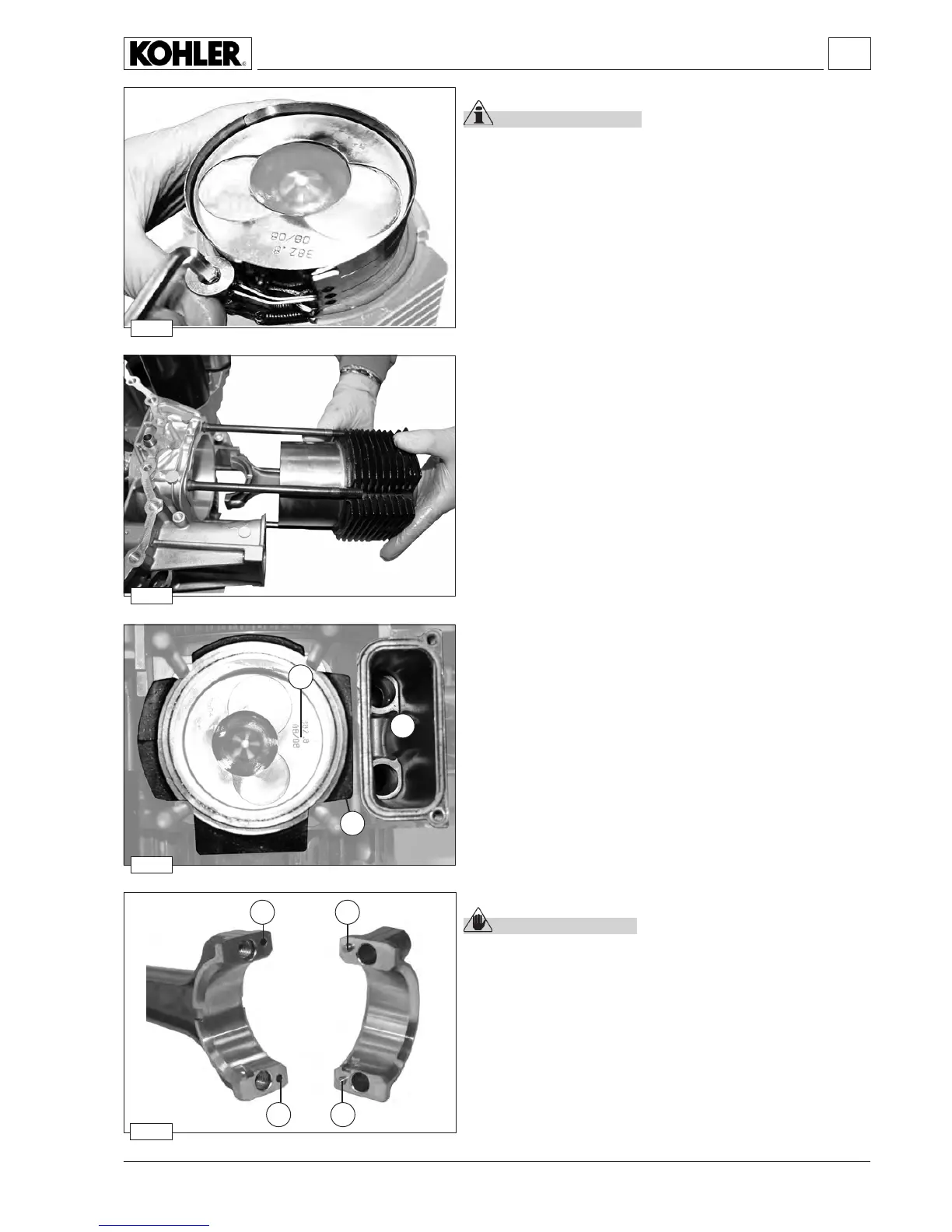

Connecting rod big end cap

Caution – Warning

While reassembling the big end, we suggest cleaning all parts

thoroughly, as well as lubricating generously in order to avoid

risks of seizure at the rst start

When reassembling, make sure pins A on the connecting rod big end

cap are in line with holes B on the connecting rod shaft.

Rings

Important

Generously lubricate the rings.

Offset the ring tips by 120°.

Use compression pliers to insert the piston into the cylinder.

Note: When introducing both the connecting rod and the piston into

the cylinder make sure that the larger crown surface A (if compared

to the combustion chamber) is on the same side as the pushrod ope-

ning B.

Insertthecylinderinthecrankcasewiththeshorterandattersideof

coolingnsC facing the push-rod opening B.

Loading...

Loading...