KW Aufzugstechnik GmbH OPERATING MANUAL DAVID-613

DAVID-D613-V125-E 13.04.2021 Page - 232 -

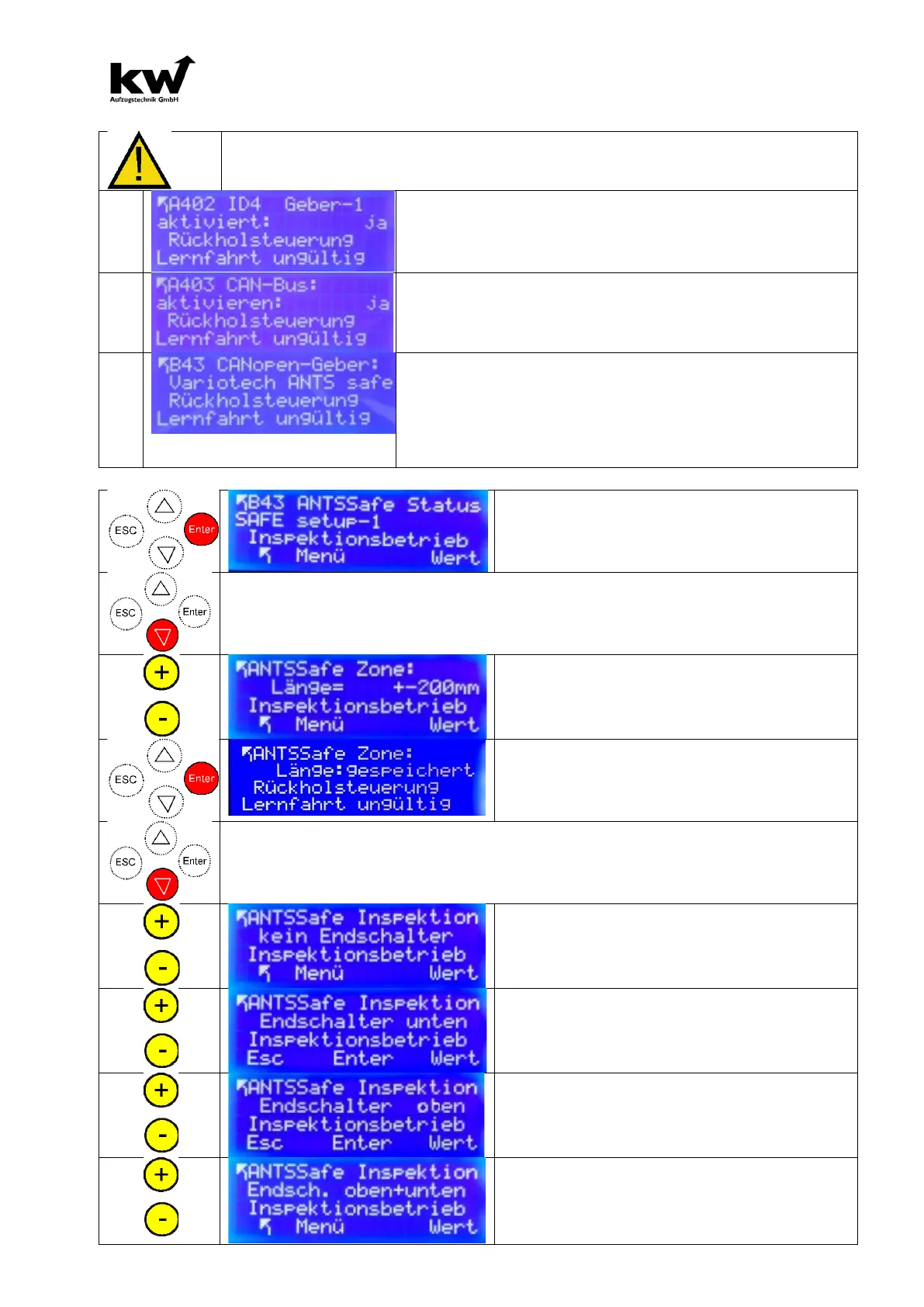

2.0 Check the software settings

Before starting the teach-in, you should read the specifications in the

attachment parameters A4 and the shaft copying menu B43.

The CANopen shaft copying system must be functionally

installed. Subsequently, the activation takes place in the

CANopen menu A402, in which a YES is entered for en-

coder 1 activated.

In menu A403 the CAN bus must be switched on. This is

done by activating in the menu item CAN bus: a YES.

In the B43 CANopen encoder menu a SAFE shaft copying

system should be set. The choices are:

1.) Variotech ANTS SAFE

2.) LIMAX-33CP SAFE ( in preparation)

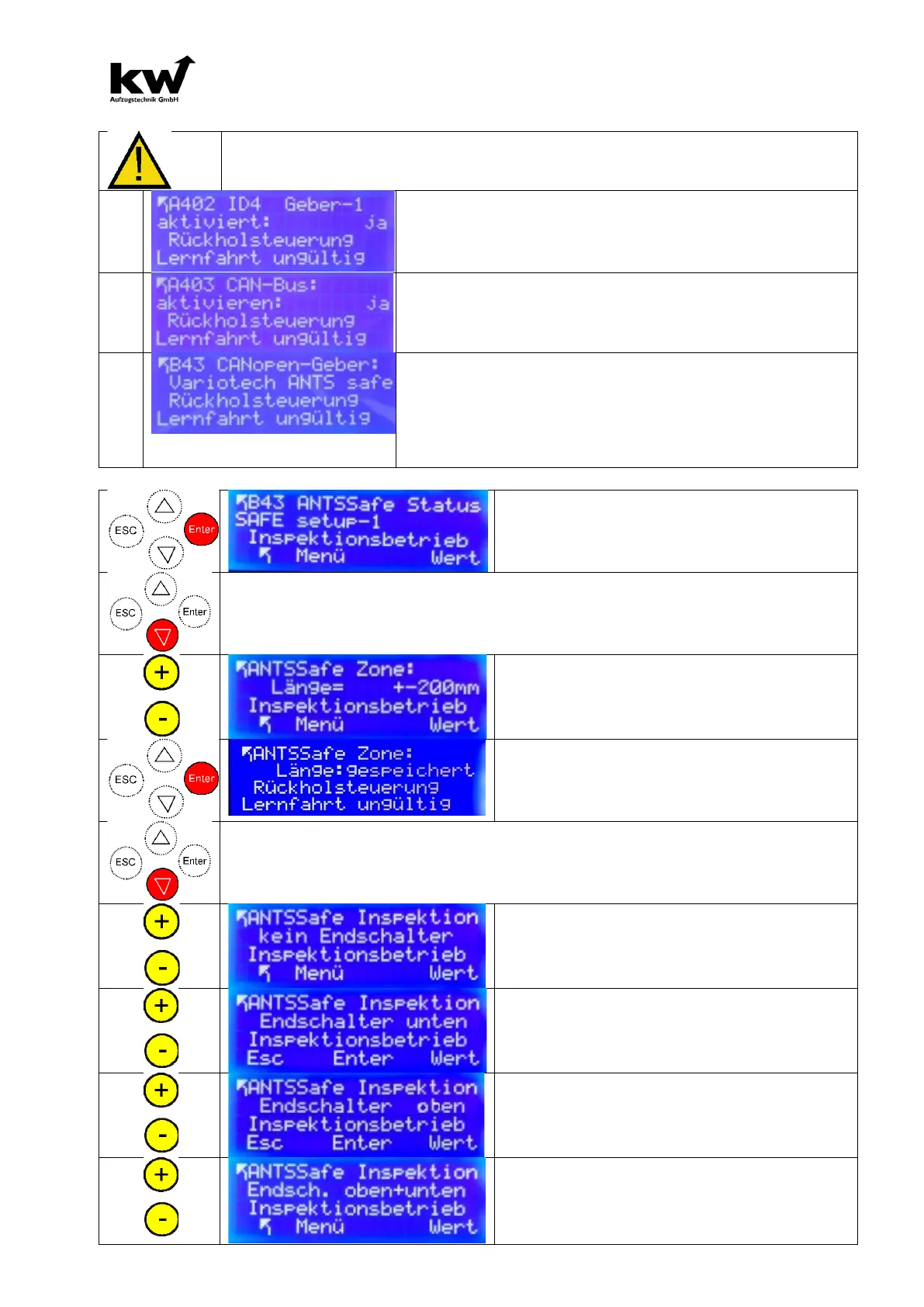

3.0 Teach-In Setup-1

After the SIL 3 shaft copying system has been

recognized, the Setup 1 parameter is dis-

played in the Status Safe parameter. By press-

ing the Enter key one enters the input routine.

3.1 Enter the zone length

This parameter is used to enter the zone length. Later, the zone length can be

shortened, but not increased!

Change value and enter default value of 200

mm.

The entry is completed with the ENTER key.

When the value is accepted, the saved mes-

sage appears.

3.2 Entering the inspection limit switch (protection mode)

With shortened pit or / and shortened pit head, inspection switches can be set. The dis-

tance to the upper or lower limit switch is 1.2m. These positions are fixed. In order to make

it possible to leave the shaft head / pit, the car is already stopped at a distance of 1.4 m!

Shaft pit and pit brow have normal height.

attitude -> No limit switch and confirm with

enter.

Shaft pit have reduced depth.

attitude -> Limit switch down and confirm

with enter.

Pit brow have recuced height.

attitude -> Limit switch up and confirm with

enter.

Shaft pit and pit brow are reduced.

attitude -> Limit switch up+down and con-

firm with enter.

Loading...

Loading...