KW Aufzugstechnik GmbH OPERATING MANUAL DAVID-613

DAVID-D613-V125-E 13.04.2021 Page - 239 -

I04a- Commissioning with CANopen Shaft-Copy KÜBLER ANTS-SAFE

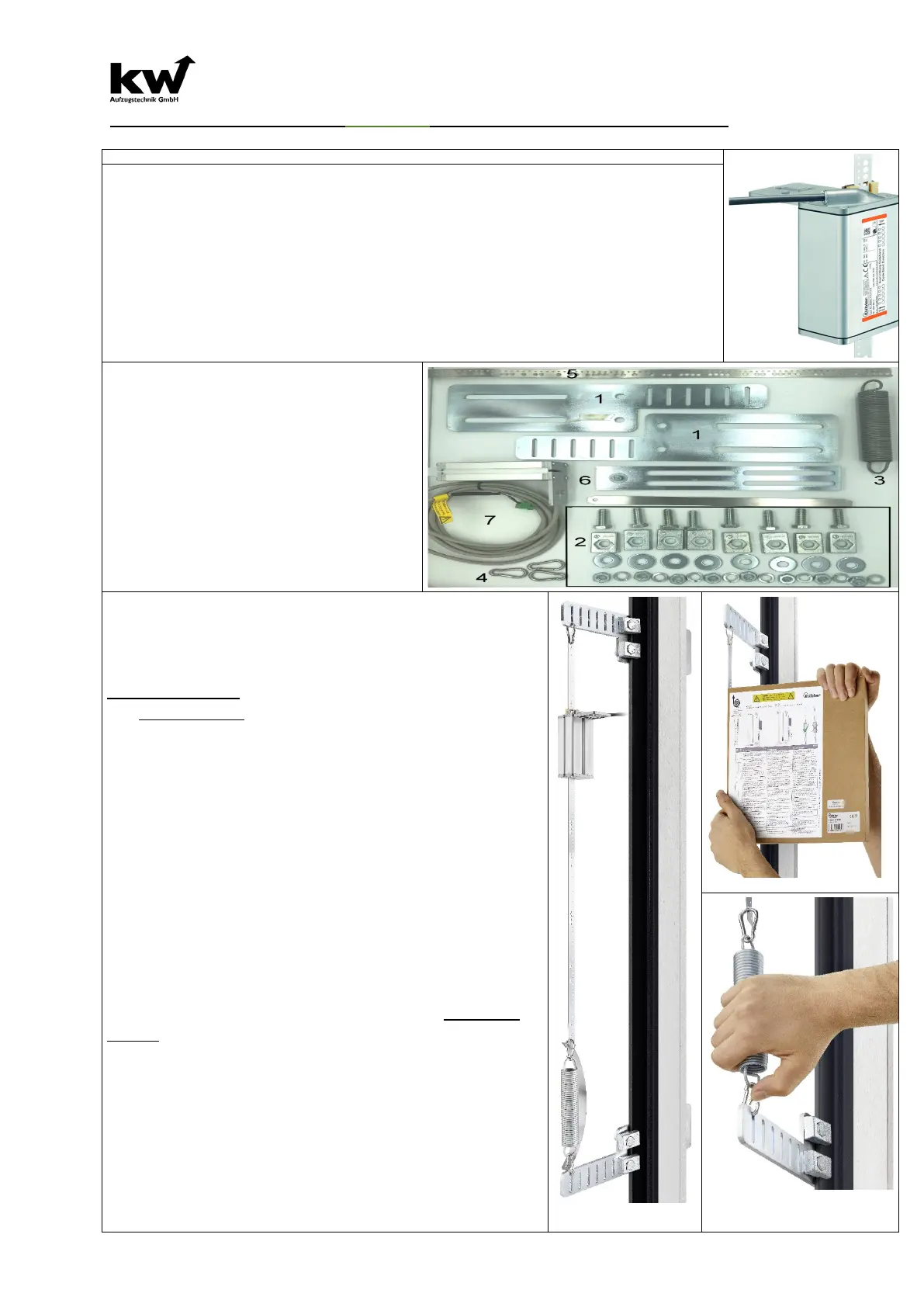

1.0 Making the mechanical Mounting

The Kübler LES02 is an absolute measuring system for determining the

position of the elevator car, consisting of the reading head, the steel band

and the mounting set.

The steel strip is fixed in the upper and

lower part of the shaft by means of

shaft flag holders. Pay attention to the correct spring preload.

The reader can be placed on the steel strip by means of a lateral opening.

The position of the large & small holes in the steel strip must be observed

when inserting!

Please also note the Kübler-LES02-SAFE installation instructions!

Mounting kit complete:

1 Shaft holder straight and angled

2 Screws & Clamps

3 Tension spring mounting at the

bottom

4 K-hook tape mounting on top

5 Steel tape

5 Holder for reader-unit with

attachment

7 Reader-unit with cable & plug

8 Stainless Steel Band

1. Mount the shaft flag holder in the shaft head in

compliance with legal and company-related safety

regulations. Depending on whether you are in-

stalling a central rail or backsack system, use the

shaft flag holder straight or angled and fasten it with

the fastening set 2.

2. Attach the upper end of the belt by inserting the

carabiner hook 4 into the shaft flag holder 1. Before

doing this, please check the orientation of the tape

using the large & small holes!

3. Drive down with the inspection and rewind the

tape directly. Please provide personal protective

equipment recommended for use.

4. Further assembly takes place in the shaft pit. Be-

fore entering the pit, ensure that the car is secured

against uncontrolled downward movement. For work

longer than 15 minutes, the car must be supported

in compliance with the safety regulations of the as-

sembly company!

5. Equivalent to steps 1 and 2, the lower shaft flag

holder 1 and the holder 2 for the magnetic tape are

to be mounted. A tension spring 3 is to be installed

and it must be saved with a Stainless steel band 8.

Decisive for the functionality is the spring preload. It

should be 170mm!

Loading...

Loading...