KW Aufzugstechnik GmbH OPERATING MANUAL DAVID-613

DAVID-D613-V125-E 13.04.2021 Page - 243 -

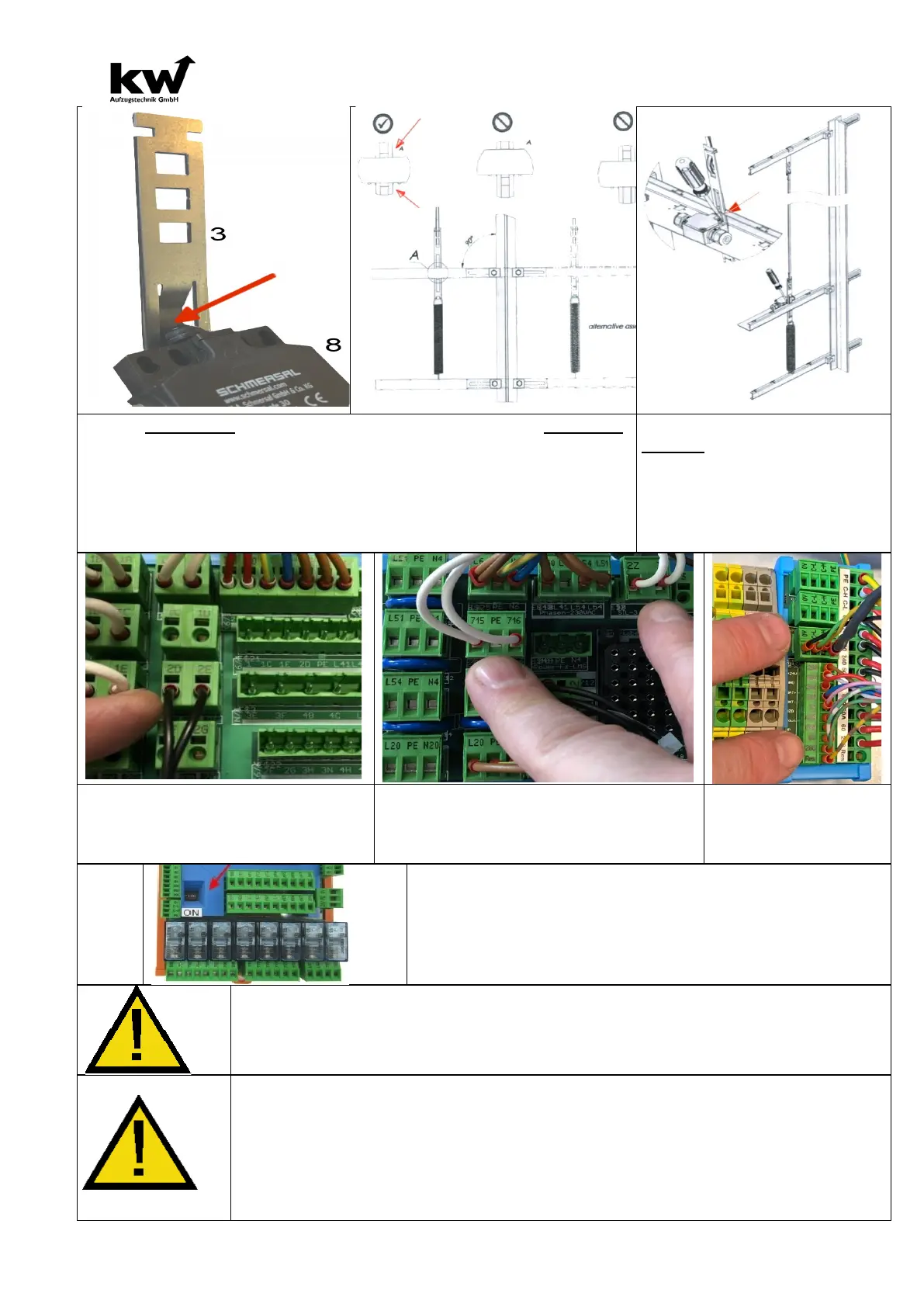

13. The belt breaker 8 is operated by the groove in the lower belt holder

3. Please fasten the belt breaker on the shaft lug holder.

The shaft flag holder with the belt breaker is now positioned so that a

mark on the belt clip is visible upwards and one downwards. The shaft

flag holder is to be tightened at a 90 degree angle with a tightening

torque of 20 Nm.

14.Subsequently, the band

breaker 8 is set sharp. To do

this, carefully remove the

plunger (actuator) with a screw-

driver

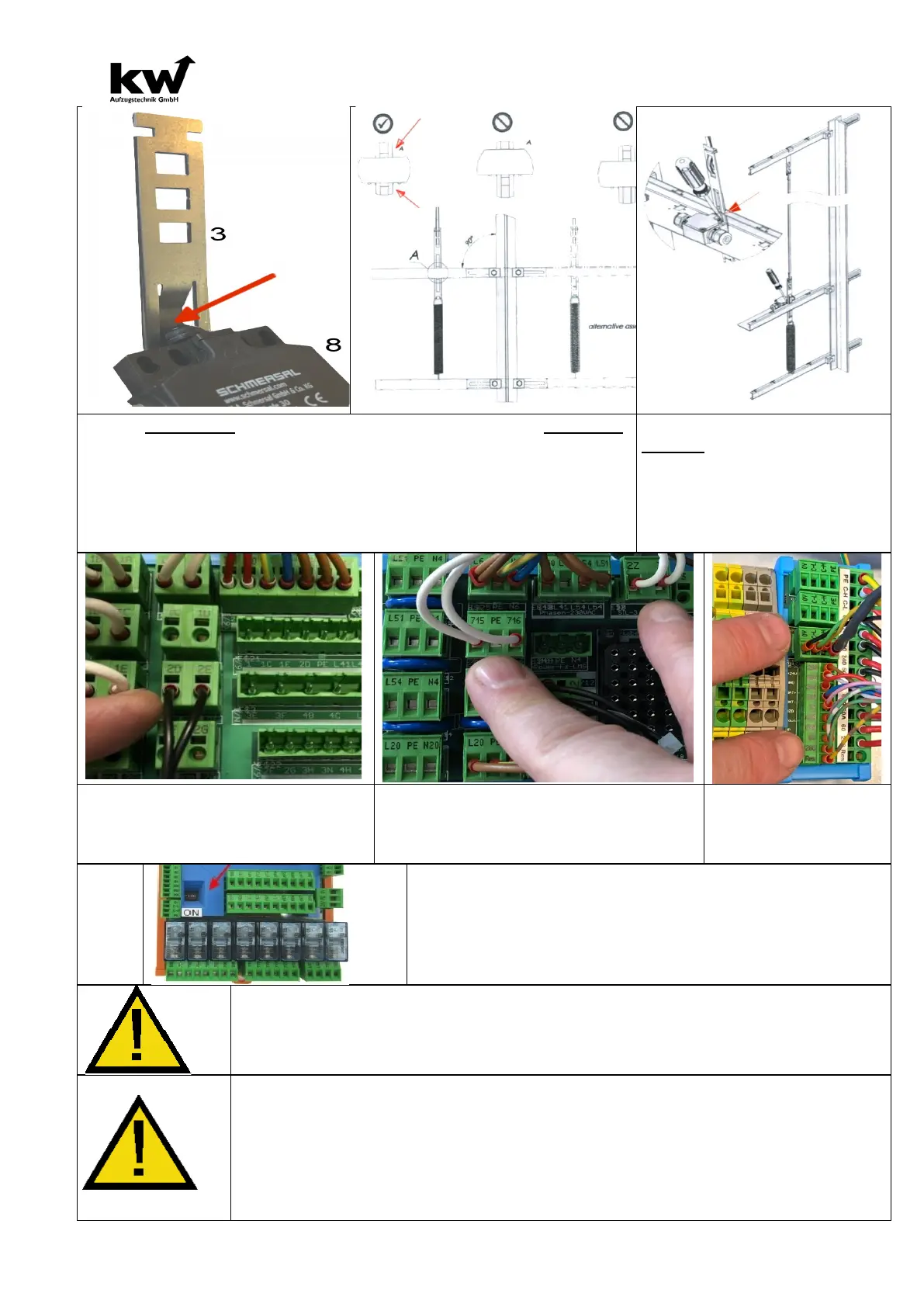

15. In the shaft pit / shaft pit box: In-

serting the belt breaker cable with

the wires 1-> 2D and 2-> 2E.

16. On the elevator car / inspection box:

Plug in the SCA cable with the 715-PE-

716 plug and the 2Z-3 plug.

box: Plug in the POI

cable with the pre-ex-

For proper operation of the CANopen bus, a termination re-

sistor is required.

If there is only one SIL-3 shaft copying system in the CANo-

pen standard, it is sufficient that all Dil switches are ON,

as shown in the picture with switch position down

!

18. Ground the sensor with the grounding cable provided by mounting the

sensor with the flat plug and the other end in the inspection box on PE!

20. Check the correct installation. Deviations and angular misalignment must be cor-

rected. An inspection trip through the shaft is the best way to do this.

21. Check the correct installation. Deviations and angular misalignment must be cor-

rected. An inspection trip through the shaft is the best way to do this.

Loading...

Loading...