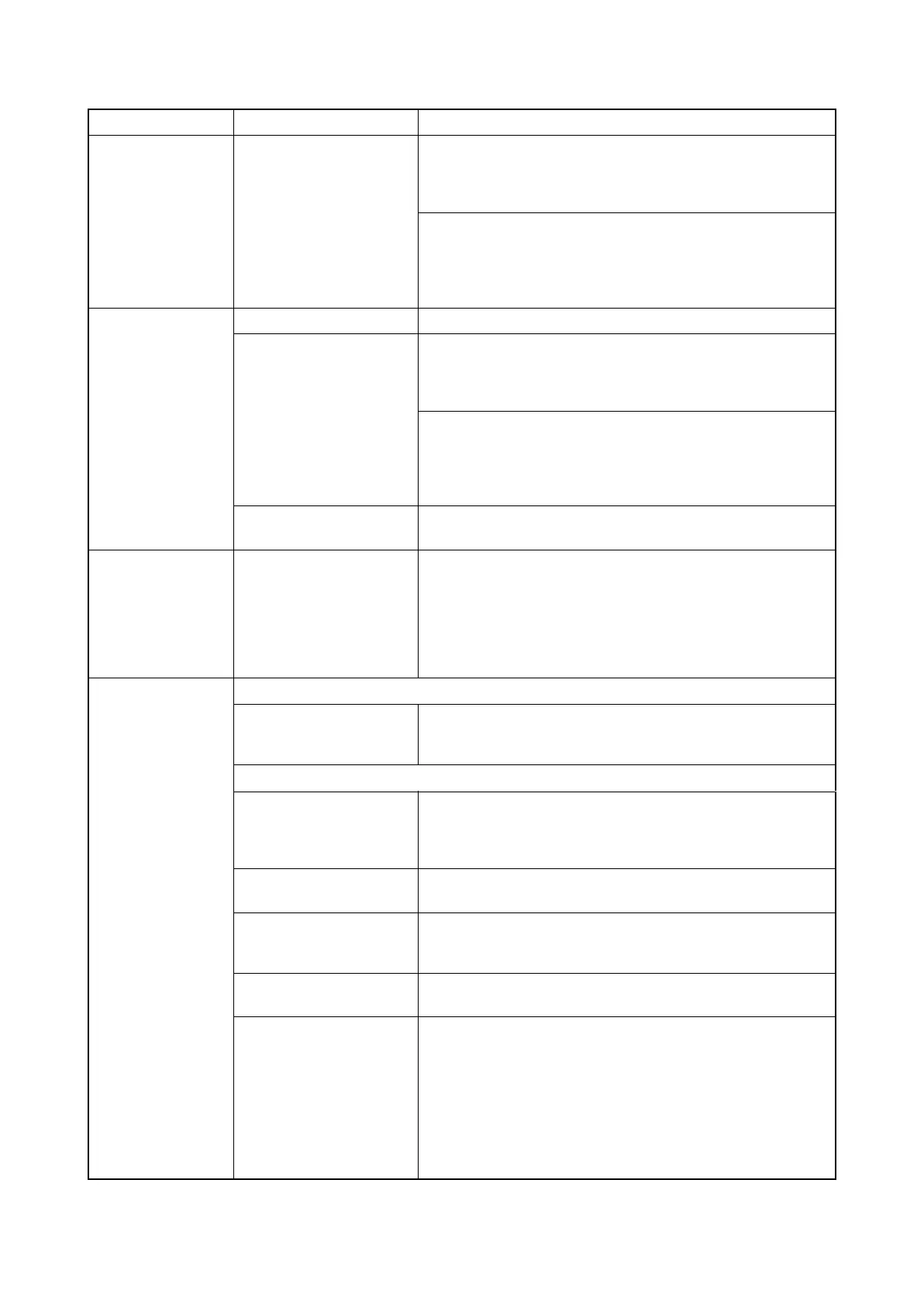

2KA

1-4-17

(25)

A paper jam in

optional document

finisher is indicated

during copying (jam

between finisher and

machine).

Jam code 80

Defective paper entry sen-

sor.

(3000-sheet document finisher)

Run maintenance item U241 and turn the paper entry sensor on

and off manually. Replace the sensor if indication of the corre-

sponding sensor is not displayed in reverse.

(Document finisher)

With 5 V DC present at CN3-1 and CN3-3 on the finisher main

PWB, check if CN3-2and CN3-4 on the finisher main PWB

remains low or high when the paper entry sensor is turned on and

off. If it does, replace the paper entry sensor.

(26)

A paper jam in

optional document

finisher is indicated

during copying

(paper jam during

paper insertion to the

finisher).

Jam code 81

Extremely curled paper. Change the paper.

Defective paper entry sen-

sor.

(3000-sheet document finisher)

Run maintenance item U241 and turn the paper entry sensor on

and off manually. Replace the sensor if indication of the corre-

sponding sensor is not displayed in reverse.

(Document finisher)

With 5 V DC present at CN3-1 and CN3-3 on the finisher main

PWB, check if CN3-2and CN3-4 on the finisher main PWB

remains low or high when the paper entry sensor is turned on and

off. If it does, replace the paper entry sensor.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

(27)

A paper jam in

optional document

finisher is indicated

during copying (fin-

isher stapler jam).

Jam code 82

Defective staple home posi-

tion sensor.

Run maintenance item U241 and turn the staple home position

sensor on and off manually. Replace the sensor if indication of the

corresponding sensor is not displayed in reverse.

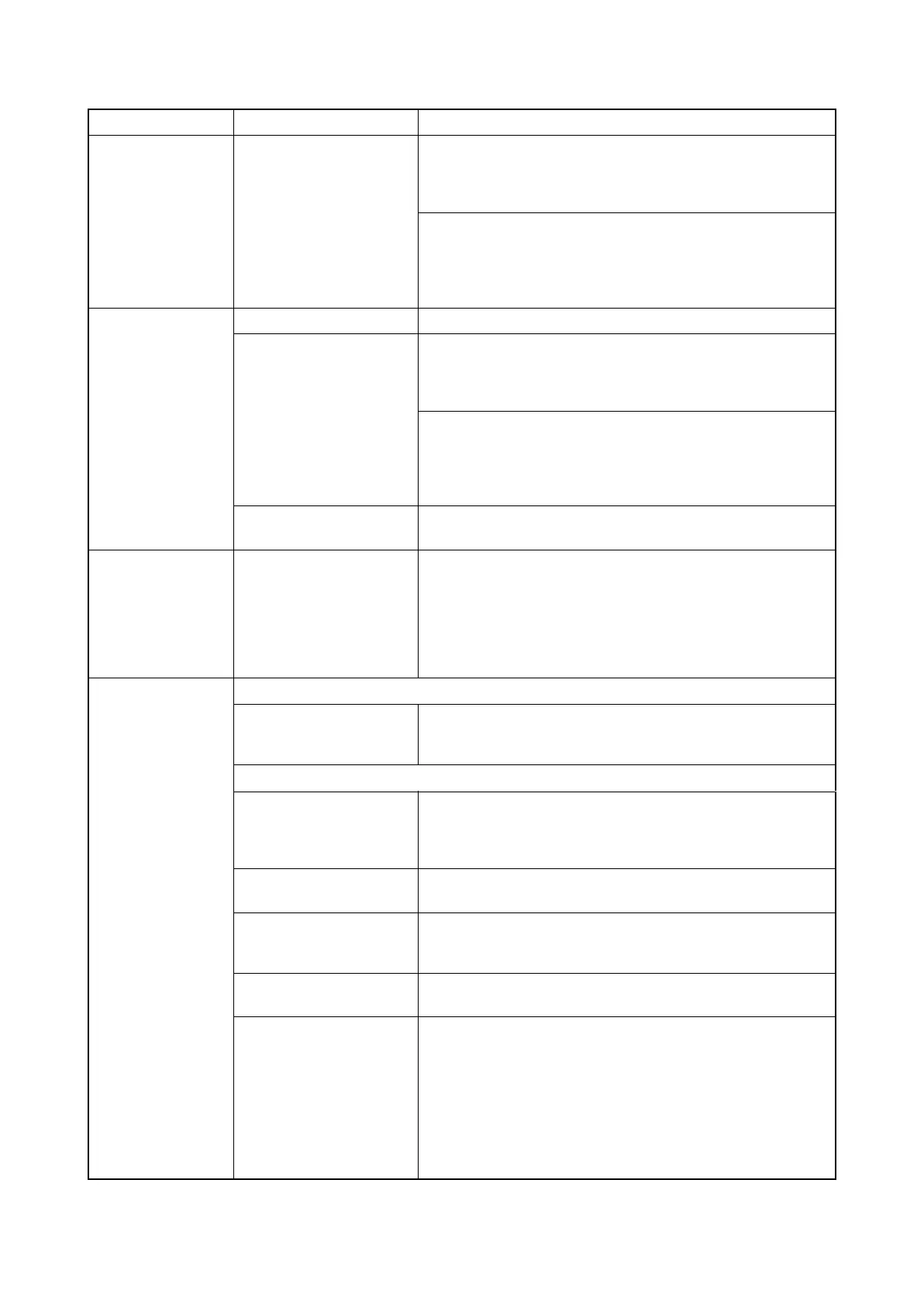

(28)

A paper jam in

optional document

finisher is indicated

during copying (eject

sensor stay jam).

Jam code 83

3000-sheet document finisher

Defective eject switch 1. Run maintenance item U241 and turn eject switch 1 on and off

manually. Replace the switch if indication of the corresponding

switch is not displayed in reverse.

Document finisher

Defective eject paper sen-

sor.

With 5 V DC present at CN7-1 on the finisher main PWB, check if

CN7-3 on the finisher main PWB remains low or high when the

eject paper sensor is turned on and off. If it does, replace the eject

paper sensor.

Check if the paper convey-

ing motor malfunctions.

Check and remedy.

Check if the eject roller and

eject pulley contact each

other.

Check and remedy.

Check if the eject guide is

deformed.

Check and remedy.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

Problem

Causes/check procedures

Corrective measures

Loading...

Loading...