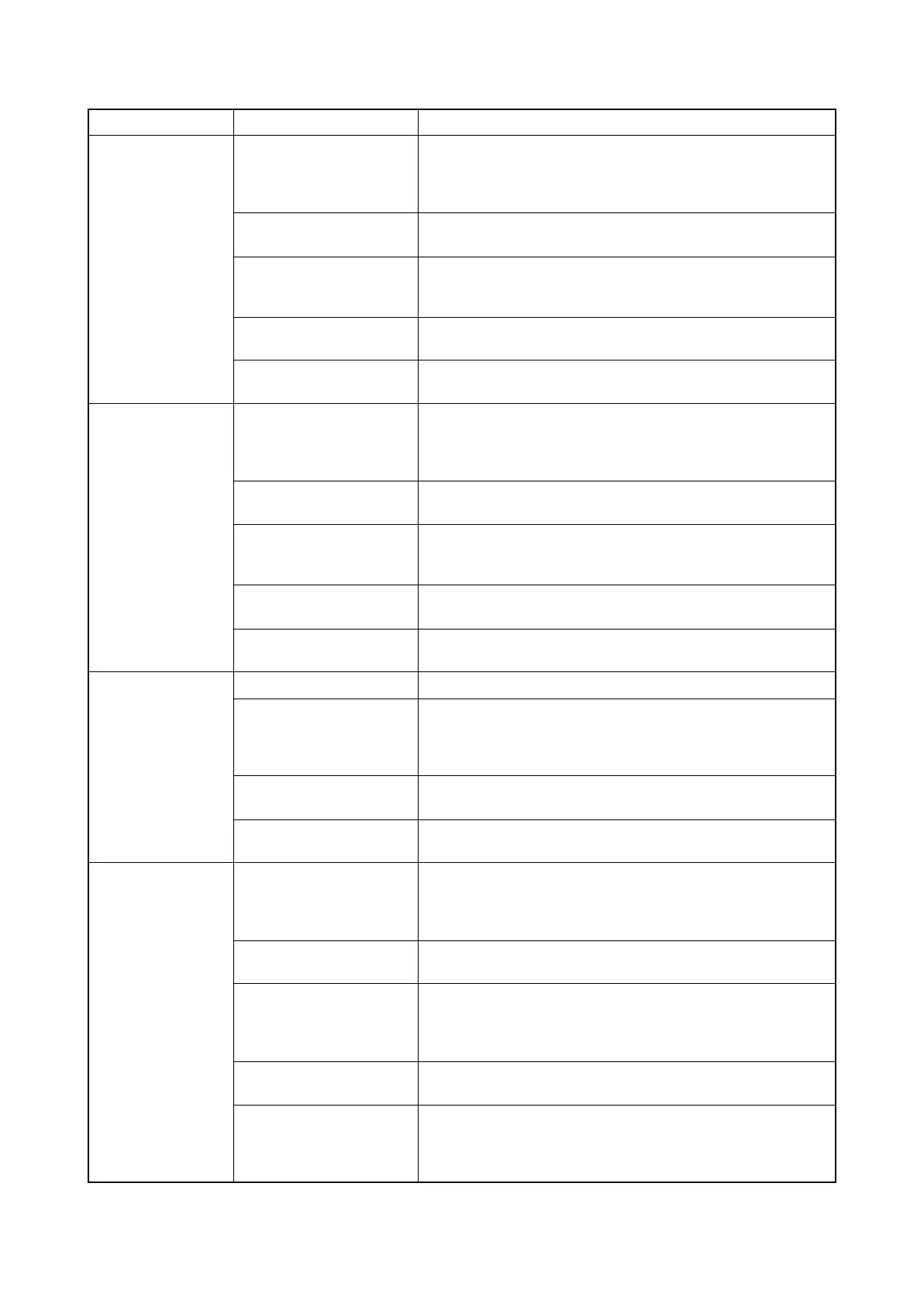

2KA

1-4-19

(35)

A paper jam in

optional document

finisher is indicated

during copying (eject

sensor non-arrival

jam).

Jam code 92

Defective eject paper sen-

sor.

With 5 V DC present at CN7-1 on the finisher main PWB, check if

CN7-3 on the finisher main PWB remains low or high when the

eject paper sensor is turned on and off. If it does, replace the eject

paper sensor.

Check if the paper convey-

ing motor malfunctions.

Check.

Check if the eject roller and

eject pulley contact each

other.

Check and remedy.

Check if the eject guide is

deformed.

Check and remedy.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

(36)

A paper jam in

optional document

finisher is indicated

during copying

(switchback sensor

jam).

Jam code 93

Defective switchback sen-

sor.

With 5 V DC present at CN3-5 on the finisher main PWB, check if

CN3-7 on the finisher main PWB remains low or high when the

switchback sensor is turned on and off. If it does, replace the

switchback sensor.

Check if the switchback

motor malfunctions.

Check.

Check if the switchback

roller and switchback pul-

ley contact each other.

Check and remedy.

Check if the switchback

guide is deformed.

Check and remedy.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

(37)

A paper jam in

optional document

finisher is indicated

during copying

(paper entry sensor

stay jam).

Jam code 94

Extremely curled paper. Change the paper.

Defective paper entry sen-

sor.

With 5 V DC present at CN3-1and CN3-3 on the finisher main

PWB, check if CN3-2 and CN3-4 on the main PCB remains low or

high when the paper entry sensor is turned on and off. If it does,

replace the paper entry sensor.

Check if the paper entry

guide is deformed.

Check and remedy.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

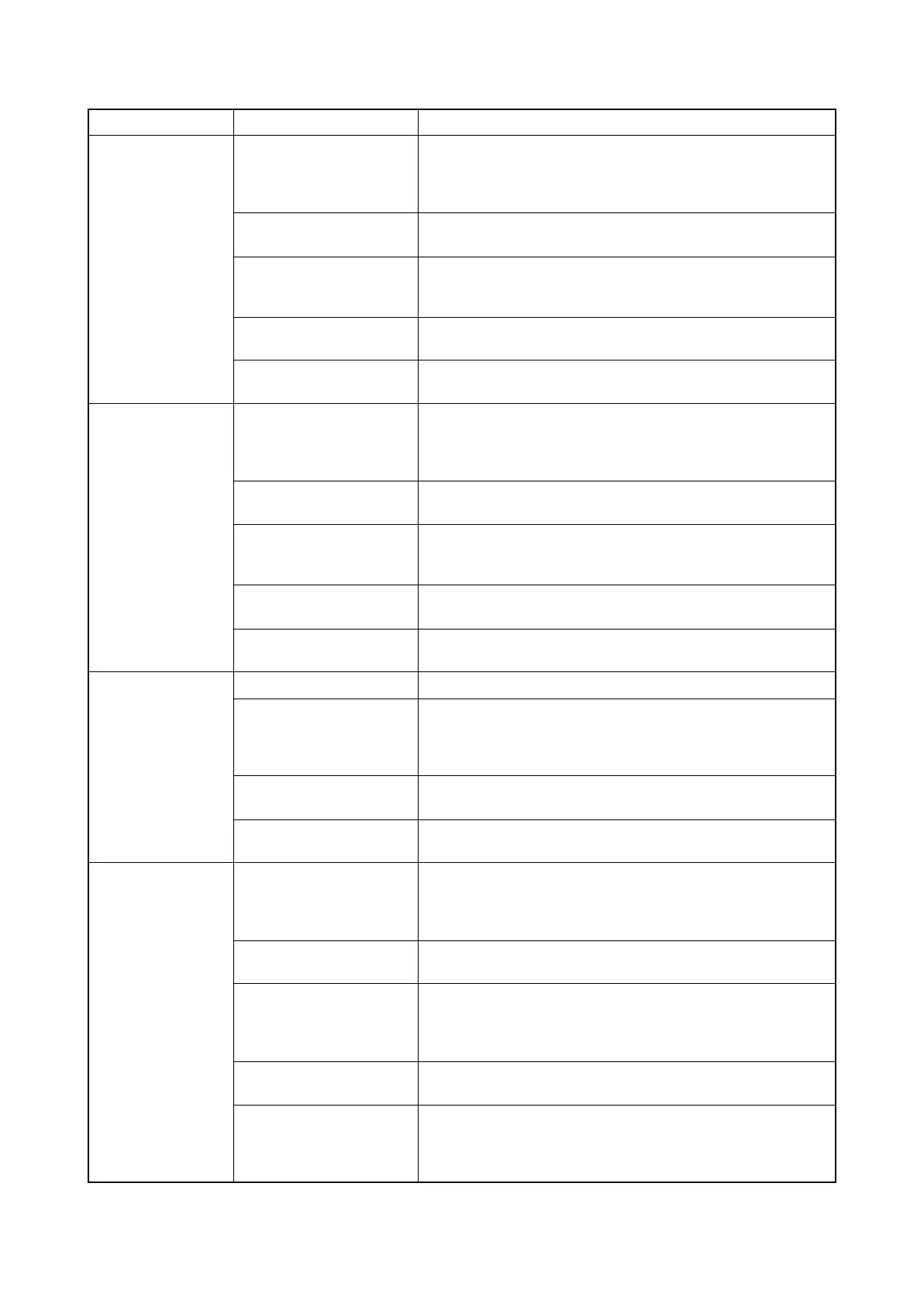

(38)

A paper jam in

optional document

finisher is indicated

during copying

(paper conveying

sensor jam).

Jam code 95

Defective paper conveying

sensor.

With 5 V DC present at CN9-1 on the finisher main PWB, check if

CN9-3 on the finisher main PWB remains low or high when the

paper conveying sensor is turned on and off. If it does, replace the

paper conveying sensor.

Check if the paper convey-

ing motor malfunctions.

Check.

Check if the paper convey-

ing roller and paper convey-

ing pulley contact each

other.

Check and remedy.

Check if the paper convey-

ing guide is deformed.

Check and remedy.

Defective finisher main

PWB.

Replace the finisher main PWB and check for correct operation.

Problem

Causes/check procedures

Corrective measures

Loading...

Loading...