ADJUSTMENT

To

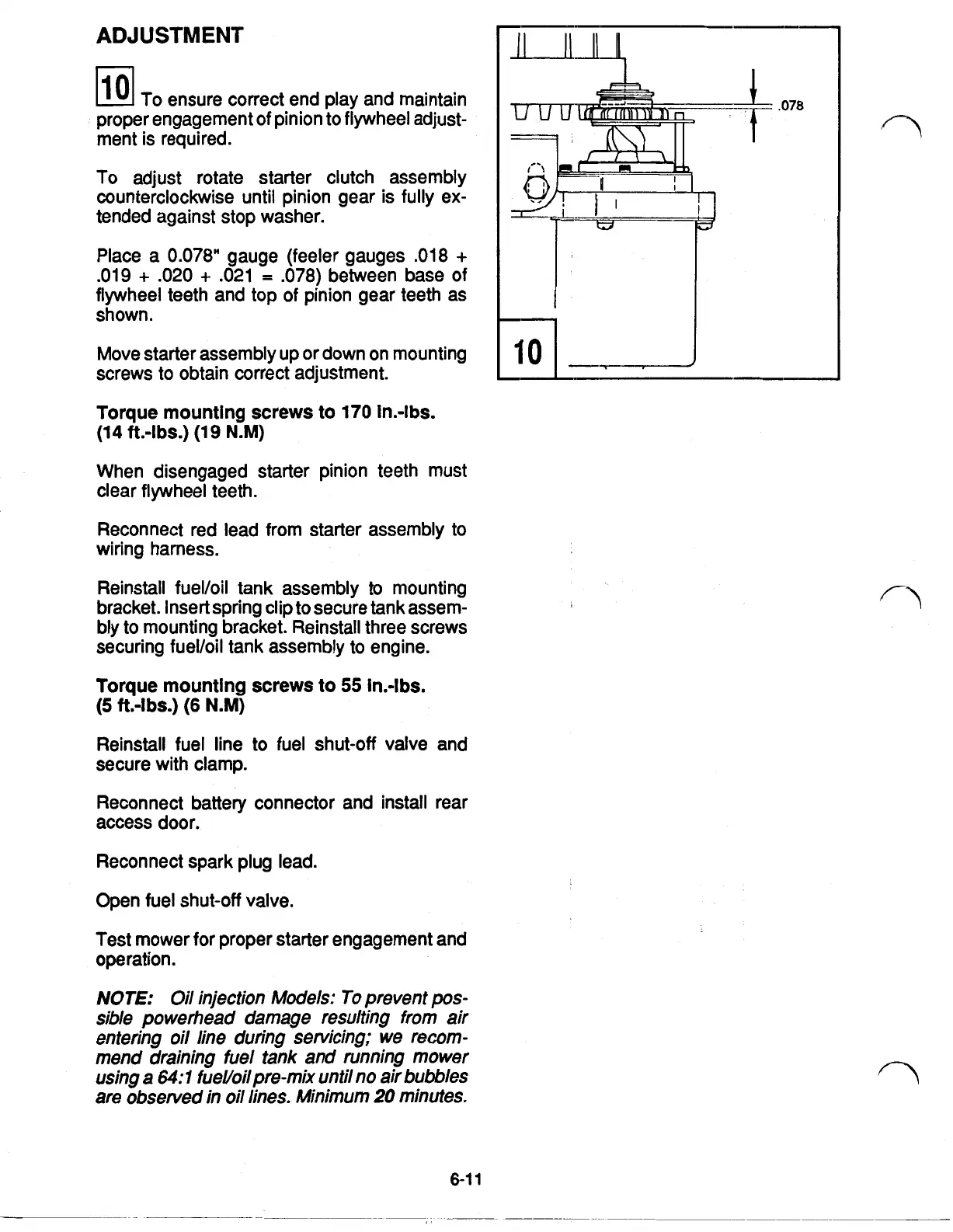

ensure correct end play and maintain

proper engagement of pinion to flywheel adjust-

ment

is

required.

To adjust rotate starter clutch assembly

counterclockwise until pinion gear is fully ex-

tended against stop washer.

Place

a

0.078" gauge (feeler gauges .018

+

.019

+

.020

+

.021

=

.078) between base of

flywheel teeth and top of pinion gear teeth as

shown.

Move starter assembly up

or

down on mounting

screws to obtain correct adjustment.

Torque mounting screws to

170

in.-lbs.

(14

ft.-lbs.)

(19

N.M)

When disengaged starter pinion teeth must

clear flywheel teeth.

Reconnect red lead from starter assembly to

wiring harness.

Reinstall fuel/oil tank assembly to mounting

bracket. Insert spring clip to secure tank assem-

bly

to

mounting bracket. Reinstall three screws

securing fuel/oil tank assembly to engine.

Torque mounting screws to

55

in.-lbs.

Reinstall fuel line

to

fuel shut-off valve and

secure with clamp.

Reconnect battery connector and install rear

access door.

Reconnect spark plug lead.

Open fuel shut-off valve.

Test mower for proper starter engagement and

operation.

NOTE:

Oil injection Models:

To

prevent

pos-

sible powerhead damage resulting from air

entering oil line during servicing; we recom-

mend draining fuel tank and running mower

using

a

64:l

fuel/oil pre-mix until no air bubbles

are observed in oil lines. Minimum

20

minutes.

(5

ft.-lbs.)

(6

N.M)

6-1

1

.078

Loading...

Loading...