7-18 LeeBoy Model 8616 Conveyor Paver

Maintenance

Element Resistance Testing

When a breaker in the control box has tripped, it must be

assumed that there may be a problem with wiring or an

actual element in the circuit.

Elements used to heat the screed are sized depending

on how much area and material they are required to

heat. The actual resistance of the element will vary

depending on what wattage the element is in the specic

application.

To know that the element is correct, you should read a

resistance between 25 and 35 ohms. If the element is

bad, the reading will be very different from this range.

The element that is bad will most likely read “open” or it

will read very little resistance (less than 1 ohm) and will

indicate a short through the element.

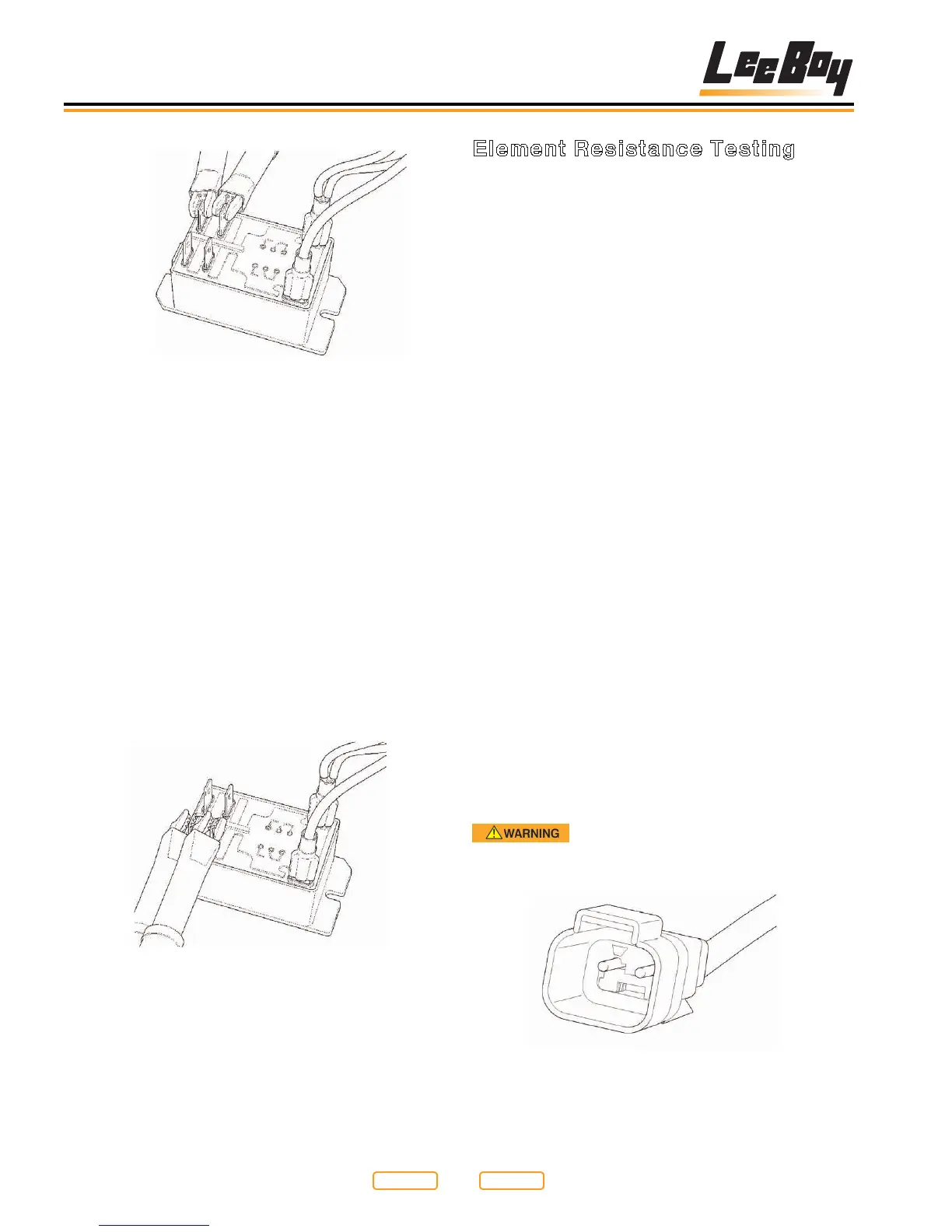

1. Disconnect element one at a time from the

connection point on the lower side of the control

box.

2. Use an ohm meter and test the resistance through

the element between the two pins in the plug at the

end of the element cable (Figure 7-18).

NOTE: You do not have to test the plug attached to the

lower side of the control box.

3. Test between the two pins shown here with an ohm

meter.

4. Test plug at end of element wires.

5. Before the element is plugged back in, check each

wire (pin) with an ohm meter test lead, and place

the other lead on a bare steel section of the screed

frame. If there is any continuity through the element

to the frame, the element is bad and must be left

disconnected or replaced.

Fire Hazard! Do not attempt to operate

an element with a known short. Replace faulty

elements and wiring before using.

Element Plug End

Figure 7-18

First Terminal Set Testing

Figure 7-16

NOTE: Without 12VDC applied to the coil of the relay,

the contact terminals should have no continuity

through them. The contacts should be “open”.

If the contacts are closed, and you do not have

12VDC applied to the coil of the relay, your

contacts are not correct, and the relay should be

replaced.

3. With the ohm meter still on the contact terminals,

apply 12VDC to the coil terminals of the relay

(Figure 7-17).

NOTE: The contact terminals should now close and

show a path through them for the power to be

applied to the electrical elements. If the relay

does not work as described above, it may be

faulty, and should be replaced.

Second Terminal Set Testing

Figure 7-17

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...