7-8 LeeBoy Model 8616 Conveyor Paver

Maintenance

50-Hour (Initial) or Weekly

Routine Maintenance

1. Check hydraulic oil and add if necessary.

• To ll, remove top of return lter, located on top of

reservoir, and pour through. If you have an air or

hydraulic pump, you can ll at charge lter. (Remove

cap and ll.)

The LeeBoy Model 8616 Conveyor

Paver hydraulic system requires clean, contaminant-

free oil (see Specications in Section 4). Take

care when working with the hydraulic system to

ensure it is completely clean.

2. Adjust conveyor chains (see Conveyor Drive Chain

Adjustment in Section 7). After adjustment,

drag chains should be about 1/2” (13 mm) from rear

square tubing of main frame. Do not let chains run

more than 2” (51 mm) below main frame sides.

3. Check auger chains, lubricate and adjust.

4. Check all battery connections and remove any

corrosion that is present. (Check cables daily.)

5. Check air cleaner, if the engine is equipped with a

dry type element.

Improperly serviced air cleaners

quickly wear out engines. In just a few hours a small

amount of dirt will wear out a set of piston rings.

Refer to your engine operator’s manual for service

information.

6. Perform any other engine preventive maintenance

as described in the engine operator’s manual.

7. Change engine oil and lters. Use drain hose on

right side of paver where access hole is located.

8. For both sides of the screed, lubricate all grease

ttings on the ight screw, the tting on the depth

screw, and the ttings on the ange bearings

located on top of the extension screed (Figure 7-1).

Grease nuts on extension screws.

9. Blow dust from generator unit.

10. Anytime the LeeBoy Model 8616 Conveyor Paver

has been repainted or the safety labels have been

removed, damaged or can not be read, a new set

of labels should be ordered and reinstalled (see

Safety Label Installation in Section 7) for safe

operation.

100-Hour or Monthly Routine

Maintenance

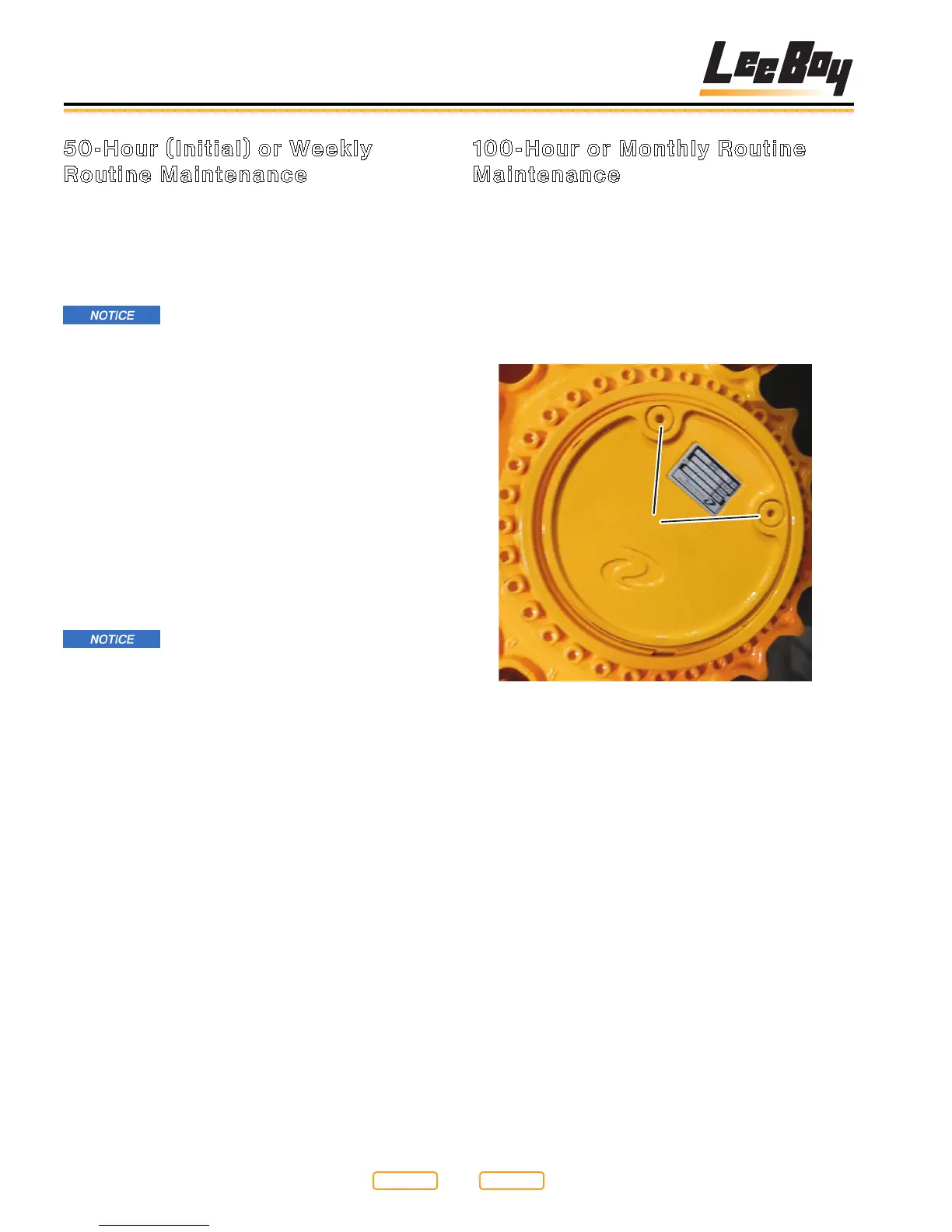

1. Position the torque hub so that either of the plugs

are at the 3 o’clock position. Remove the plug at the

3 o’clock position (Figure 7-4,1). If oil comes out, no

oil is needed. Insert plug and tighten. If oil does not

come out, remove the plug at the 12 o’clock position

and ll torque hub with 80W-90 gear oil until oil

starts to appear at the other hole. Replace both

plugs and repeat process on other torque hub.

1

Torque Hub Location

Figure 7-4

1 - Plugs

2. Replace dry type air lter, if equipped. Refer to your

engine operator’s manual for service information.

3. Change engine oil. To assure complete removal of

contaminants in the oil, perform the oil change while

engine is warm.

4. After draining used oil, clean and reinstall drain

plug and ll crankcase to the full mark with

manufacturer’s recommended oil. Change oil lter at

every other oil change (15W-40 Motor Oil).

5. Change engine oil and lters. Use the drain hose

stored on the right hand side of the machine.

6. Perform any other engine preventive maintenance

as described in the engine operator’s manual.

7. Check and adjust all chains, as required (see

Maintenance Adjustments in Section 7).

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...