6-22 LeeBoy Model 8616 Conveyor Paver

Operation

necessary to reduce the loading angle.

NOTE: If you have a problem unloading the paver -

STOP - LOOK - THINK.

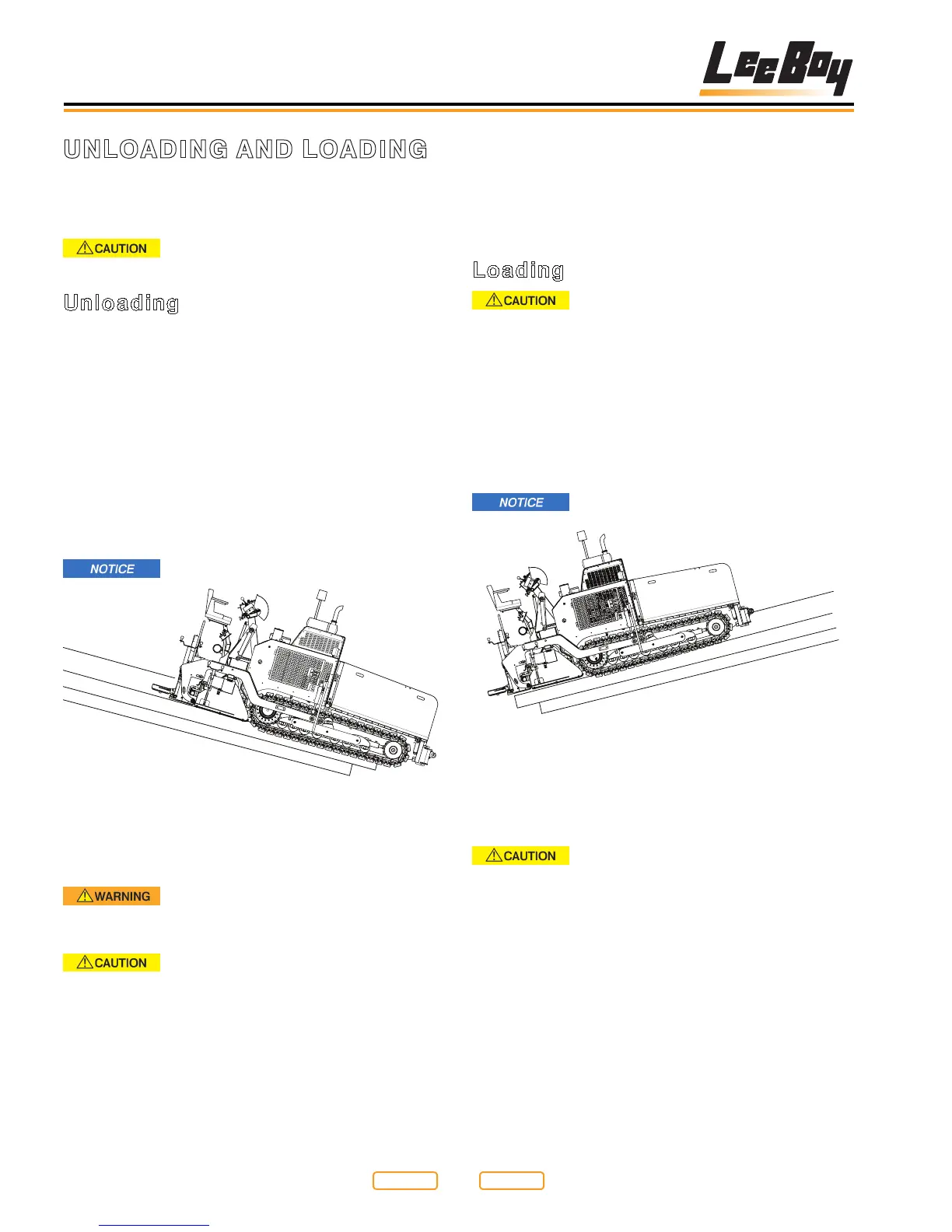

5. Move paver forward down the ramp as shown

(Figure 6-22).

Loading

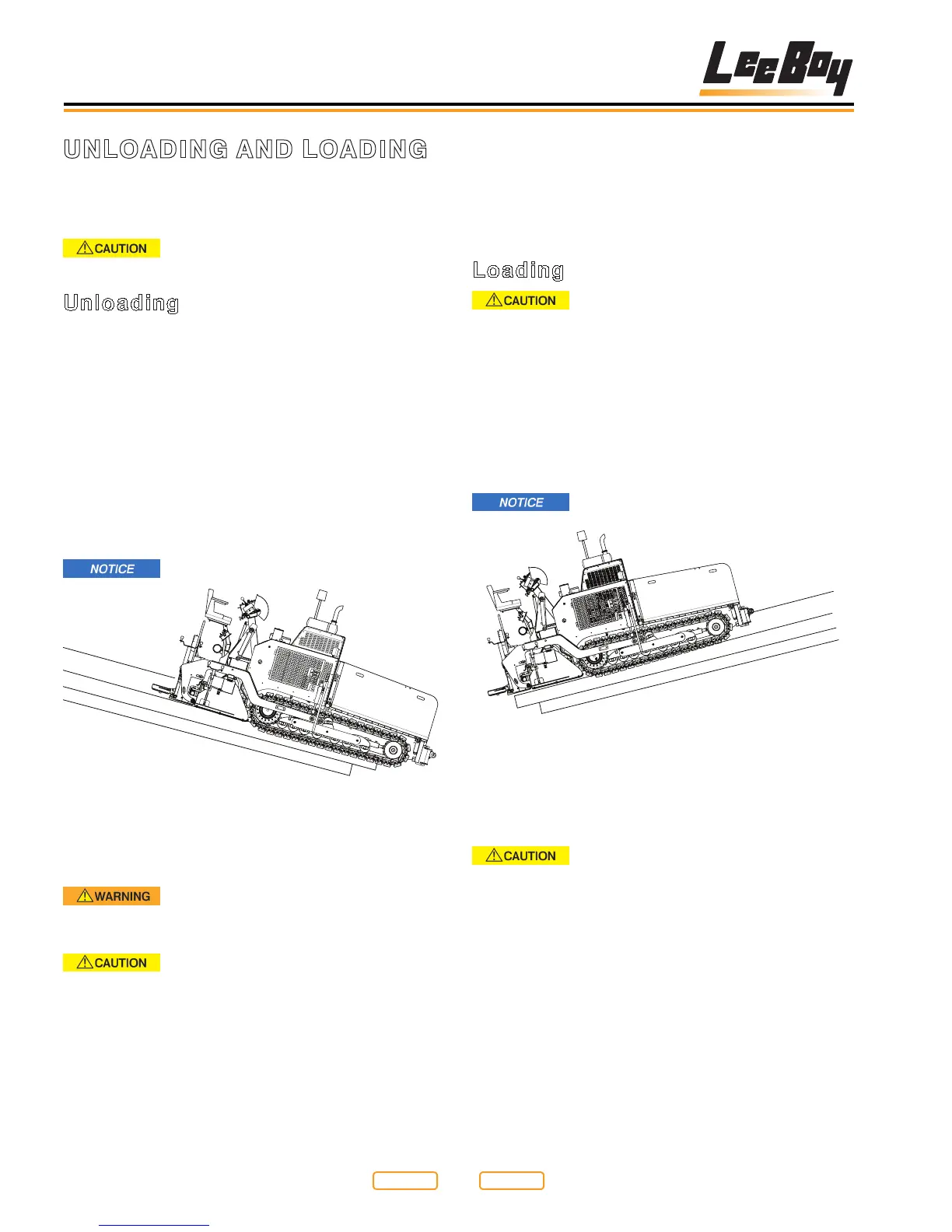

Paver must be loaded screed end rst

to prevent damage (Figure 6-23).

1. Move paver to base of ramp. Line up tracks with the

ramp.

2. Make sure:

a. Screed position is - UP

b. Extendable screed - IN

c. Gates below auger - CLOSED

Never back up with cutoff gates open.

Incorrect Loading Position

Figure 6-23

NOTE: Always have a helper on the ground that can

assist the operator in moving the paver onto the

transport.

To prevent an excessive shock to the

undercarriage and throughout the paver, reduce

traveling speeds to a minimum before the paver

tracks come in contact with loading ramps or an

abrupt change in the surface. If encountered, the

track drive sprocket or possible other components

may be damaged because of the excessive shock.

3. Loadpaverscreedendrst.Setthrottleat1/2

operating RPM and steering control lever so paver

moves very slowly onto the ramp.

4. With the steering control joysticks slowly guide the

paver up the ramp.

5. Place paver in center of trailer or desired position.

Unloading And Loading

Trailers used to haul the paver should have ample

capacity to carry the weight of the paver. Place the

trailer in a clear, level area for loading or unloading.

Work slowly and carefully to avoid

accidents. Keep the area clear.

Unloading

1. Remove tie down equipment.

2. Start and warm up engine.

3. Set throttle at 1/2 operating RPM. Set steering

control lever so paver moves very slowly.

4. Make sure:

a. Screed position - UP

b. Auger extensions removed

c. Extendible screed - IN

d. Gates below augers - CLOSED

Never back up with cutoff gates open.

Correct Unloading

Figure 6-22

NOTE: A man should always be on the ground to assist

the operator in the unloading procedure.

Make sure engine is operating at a high

enough RPM so that the hydraulic pump is providing

sufcient ow to operate all functions properly.

Do not let the screed strike the ramp

when moving off the ramp. This can break the

bearings on the thickness control screws or welds

on the leveling arms. A longer ramp or blocks may be

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...