7-22 LeeBoy Model 8616 Conveyor Paver

Maintenance

Do not loosen, or remove, the hydraulic

oil reservoir ller cap when the hydraulic oil is hot.

Only loosen the ller cap when the oil is at a warm

temperature. Always loosen the ller cap slowly to

relieve any pressure in the hydraulic oil reservoir.

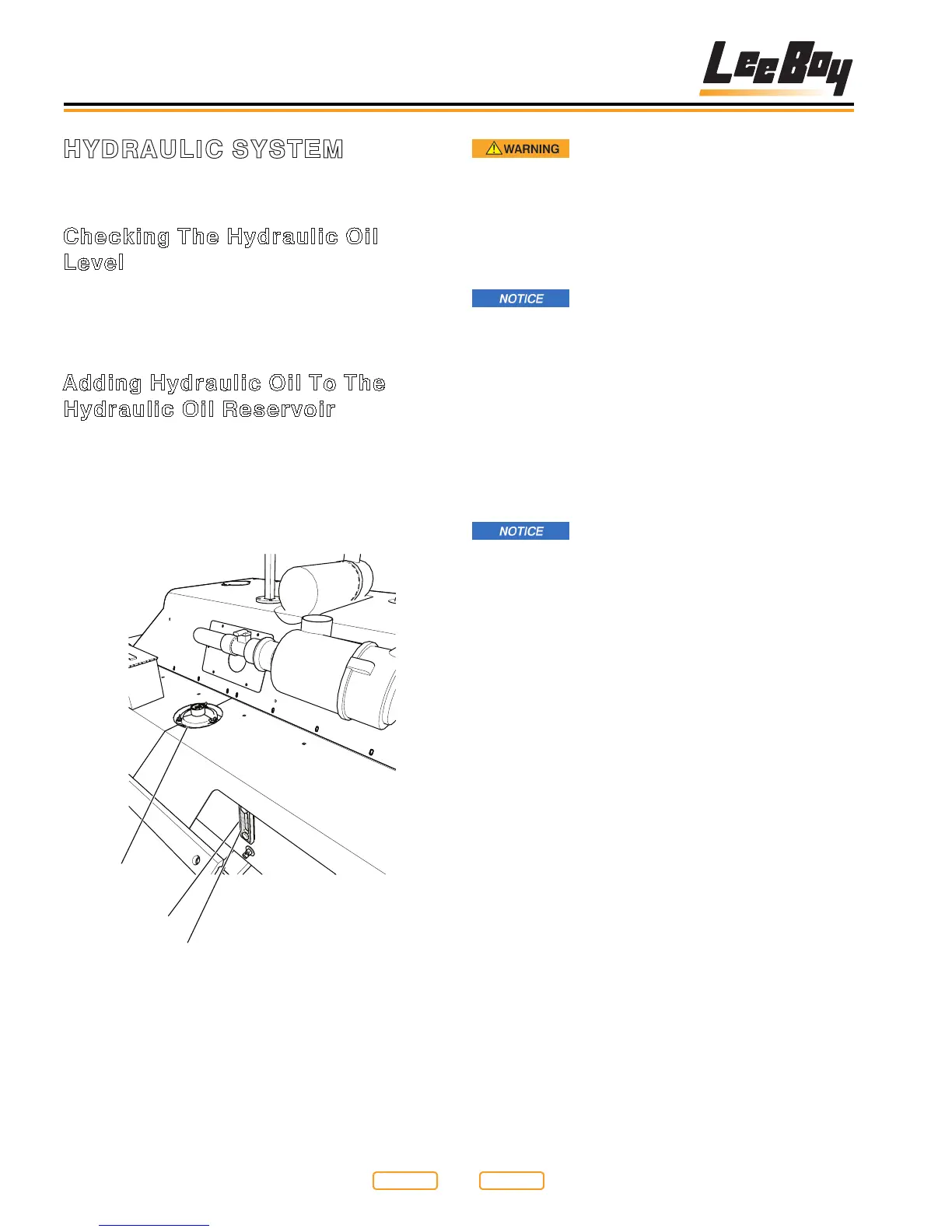

1. Locate and remove cap on top of hydraulic oil

reservoir (Figure 7-19,1).

Take care when working with the

hydraulic system to ensure it is completely clean.

NOTE: Do not use unltered hydraulic oil. The new

hydraulic oil must be ltered before it enters the

hydraulic oil reservoir.

NOTE: Keep the oil level of the hydraulic oil reservoir,

at the correct level. An air space is designed

into the hydraulic oil reservoir and allows for oil

expansion, at warm temperatures. The hydraulic

oil reservoir will have a low pressure in it at

system operating temperatures.

Do not over ll the hydraulic oil

reservoir.

2. Add ltered hydraulic oil through opening until

oil is seen in the hydraulic oil sight glass and is

approximately 1/2” below the black line near the top

(Figure 7-19,2). Do not overll.

3. Replace cap.

Hydraulic System

The hydraulic motors and the hydraulic cylinders use

the same hydraulic oil reservoir and hydraulic oil supply.

Checking The Hydraulic Oil

Level

Check the hydraulic reservoir oil level, one time each

day, by the sight glass on the reservoir as seen on

the left side of the paver. Check the oil level when the

hydraulic oil is at normal operating temperature only.

Adding Hydraulic Oil To The

Hydraulic Oil Reservoir

The hydraulic reservoir oil level must be visible in the

sight glass to be at the correct level. If the hydraulic oil

level is below the red line (Figure 7-19,3) or not visible

in the sight glass, the correct, ltered hydraulic oil (see

Specications in Section 4) must be added to the

hydraulic oil reservoir until the oil level is correct.

1

2

3

Hydraulic Oil Tank Fill

Figure 7-19

1 - Oil Fill Fitting

2 - Black Line

3 - Red Line

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...