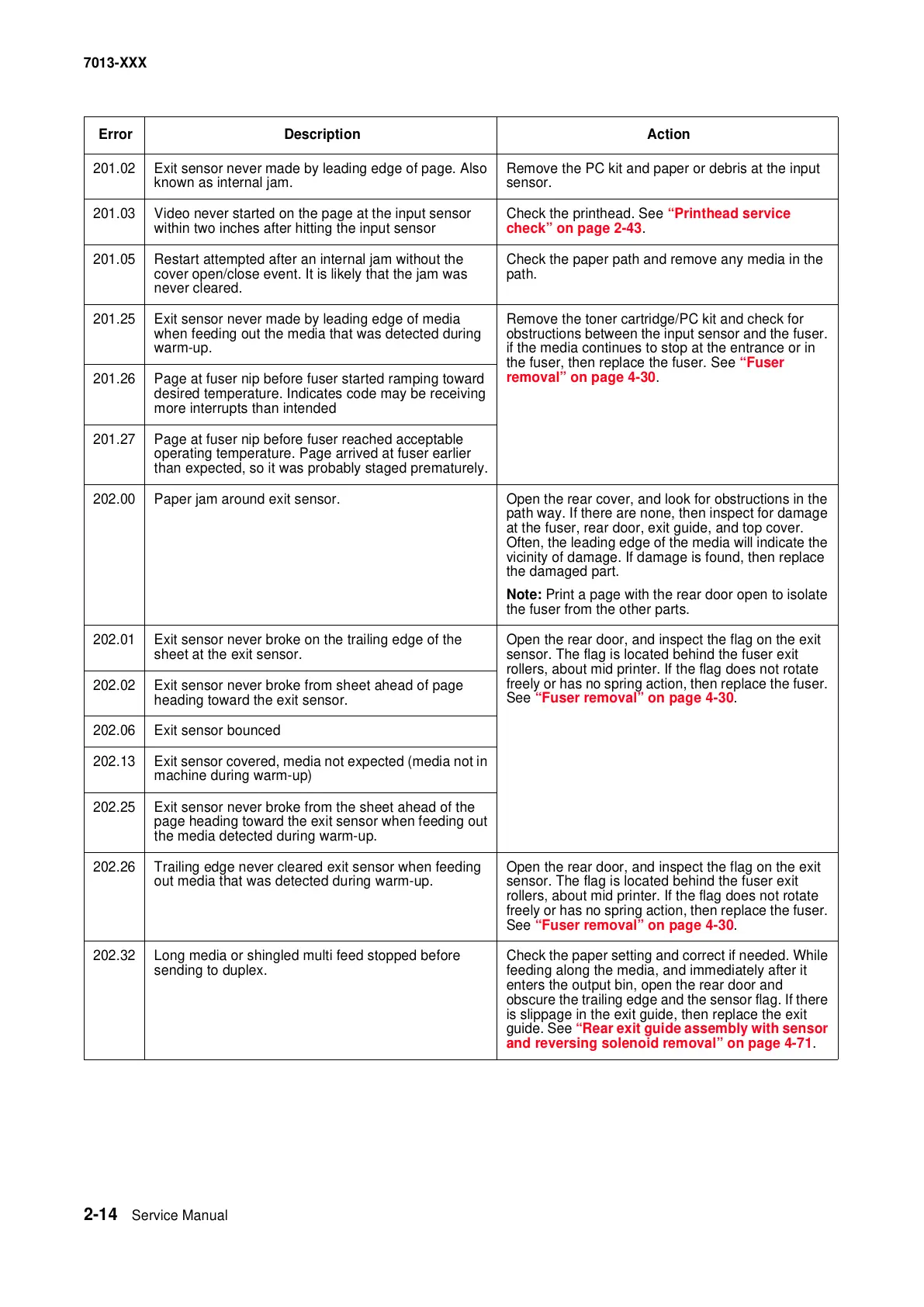

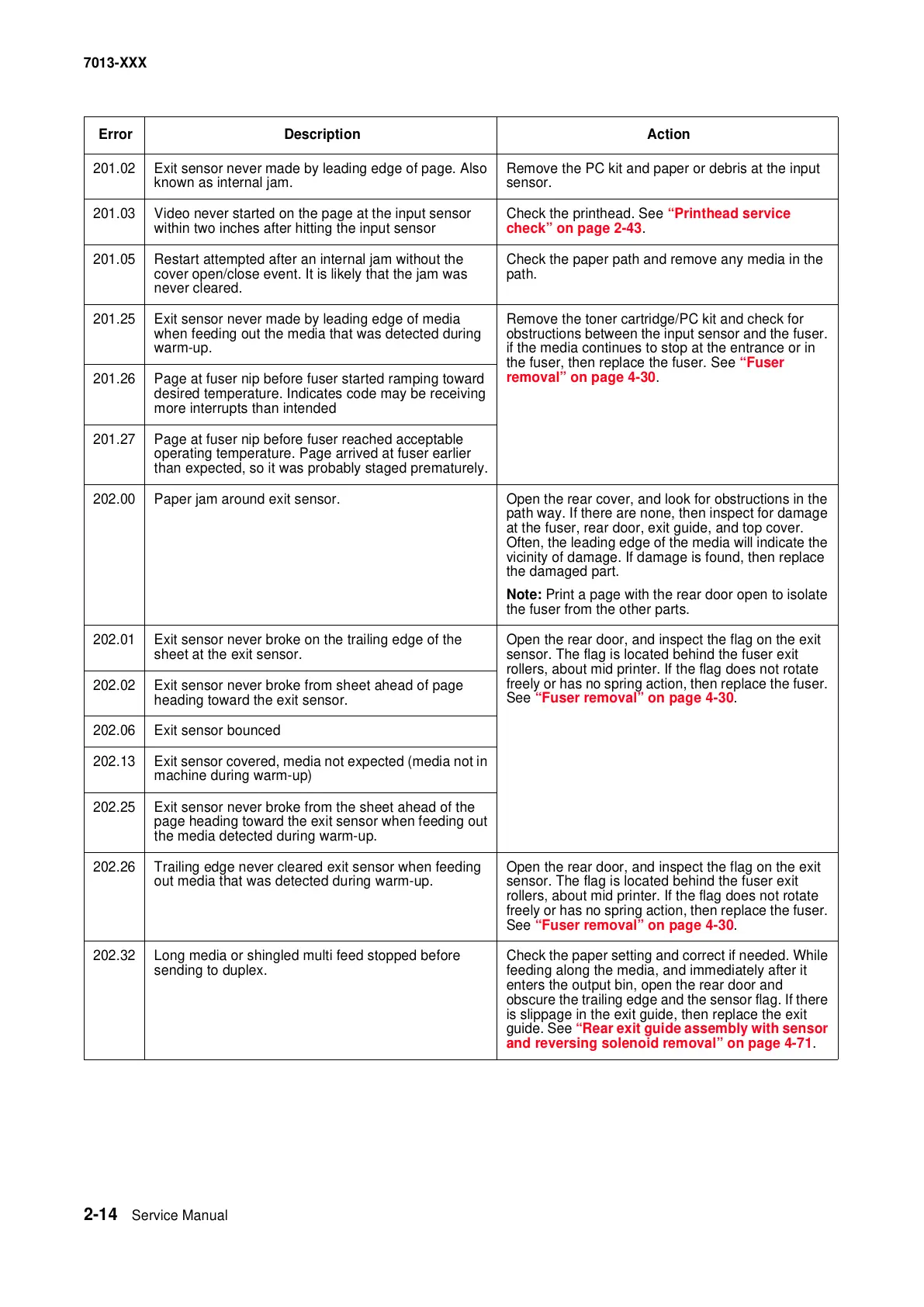

2-14 Service Manual

7013-XXX

201.02 Exit sensor never made by leading edge of page. Also

known as internal jam.

Remove the PC kit and paper or debris at the input

sensor.

201.03 Video never started on the page at the input sensor

within two inches after hitting the input sensor

Check the printhead. See “Printhead service

check” on page 2-43.

201.05 Restart attempted after an internal jam without the

cover open/close event. It is likely that the jam was

never cleared.

Check the paper path and remove any media in the

path.

201.25 Exit sensor never made by leading edge of media

when feeding out the media that was detected during

warm-up.

Remove the toner cartridge/PC kit and check for

obstructions between the input sensor and the fuser.

if the media continues to stop at the entrance or in

the fuser, then replace the fuser. See “Fuser

removal” on page 4-30.

201.26 Page at fuser nip before fuser started ramping toward

desired temperature. Indicates code may be receiving

more interrupts than intended

201.27 Page at fuser nip before fuser reached acceptable

operating temperature. Page arrived at fuser earlier

than expected, so it was probably staged prematurely.

202.00 Paper jam around exit sensor. Open the rear cover, and look for obstructions in the

path way. If there are none, then inspect for damage

at the fuser, rear door, exit guide, and top cover.

Often, the leading edge of the media will indicate the

vicinity of damage. If damage is found, then replace

the damaged part.

Note: Print a page with the rear door open to isolate

the fuser from the other parts.

202.01 Exit sensor never broke on the trailing edge of the

sheet at the exit sensor.

Open the rear door, and inspect the flag on the exit

sensor. The flag is located behind the fuser exit

rollers, about mid printer. If the flag does not rotate

freely or has no spring action, then replace the fuser.

See “Fuser removal” on page 4-30.

202.02 Exit sensor never broke from sheet ahead of page

heading toward the exit sensor.

202.06 Exit sensor bounced

202.13 Exit sensor covered, media not expected (media not in

machine during warm-up)

202.25 Exit sensor never broke from the sheet ahead of the

page heading toward the exit sensor when feeding out

the media detected during warm-up.

202.26 Trailing edge never cleared exit sensor when feeding

out media that was detected during warm-up.

Open the rear door, and inspect the flag on the exit

sensor. The flag is located behind the fuser exit

rollers, about mid printer. If the flag does not rotate

freely or has no spring action, then replace the fuser.

See “Fuser removal” on page 4-30.

202.32 Long media or shingled multi feed stopped before

sending to duplex.

Check the paper setting and correct if needed. While

feeding along the media, and immediately after it

enters the output bin, open the rear door and

obscure the trailing edge and the sensor flag. If there

is slippage in the exit guide, then replace the exit

guide. See “Rear exit guide assembly with sensor

and reversing solenoid removal” on page 4-71.

Error Description Action

Loading...

Loading...