Chapter 7 Maintenance

Chapter 7 Maintenance

To keep the XGT Panel best, examine the XGT Panel.

7.1 Maintenance

Because an error may be developed by environment, the periodic maintenance is needed. You should check the following

categories once or twice every 6 months.

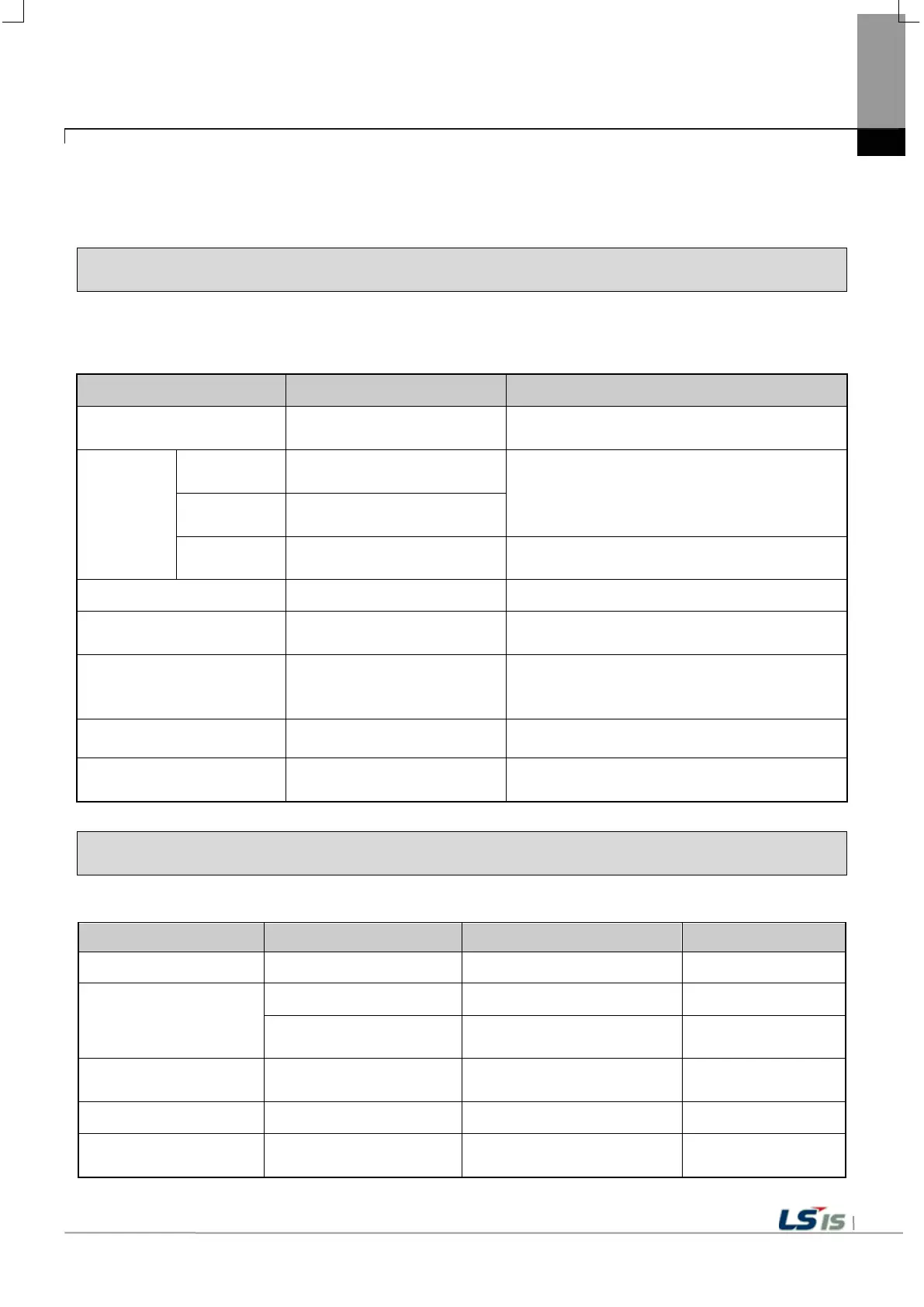

Maintenance category Criterion Action

Power

Within the power change range

−

Modify the source of electric power in order to be in

the fluctuation range of a permissible voltage.

Environment

Operating

temperature

0 ~ + 50℃

Modify the operating temperature and humidity to be

proper.

Operating

humidity

10 ~ 85%RH

Vibration No vibration

Use the anti-vibration rubber and make a count

measure.

Getting loose of power terminal There is no unwinding Screw the unwound terminal.

Getting loose of

communication connector

There is no unwinding Screw the unwound terminal.

Reserved part

Amount of reserved part and

reservation

Check the status

Refill the insufficiency and improve the reservation.

Gasket installation status

No gap between the gasket and

Replace gasket or affix brackets firmly

Gasket status No damage or deterioration Replace gasket

7.2 Daily Maintenance

Check the followings daily.

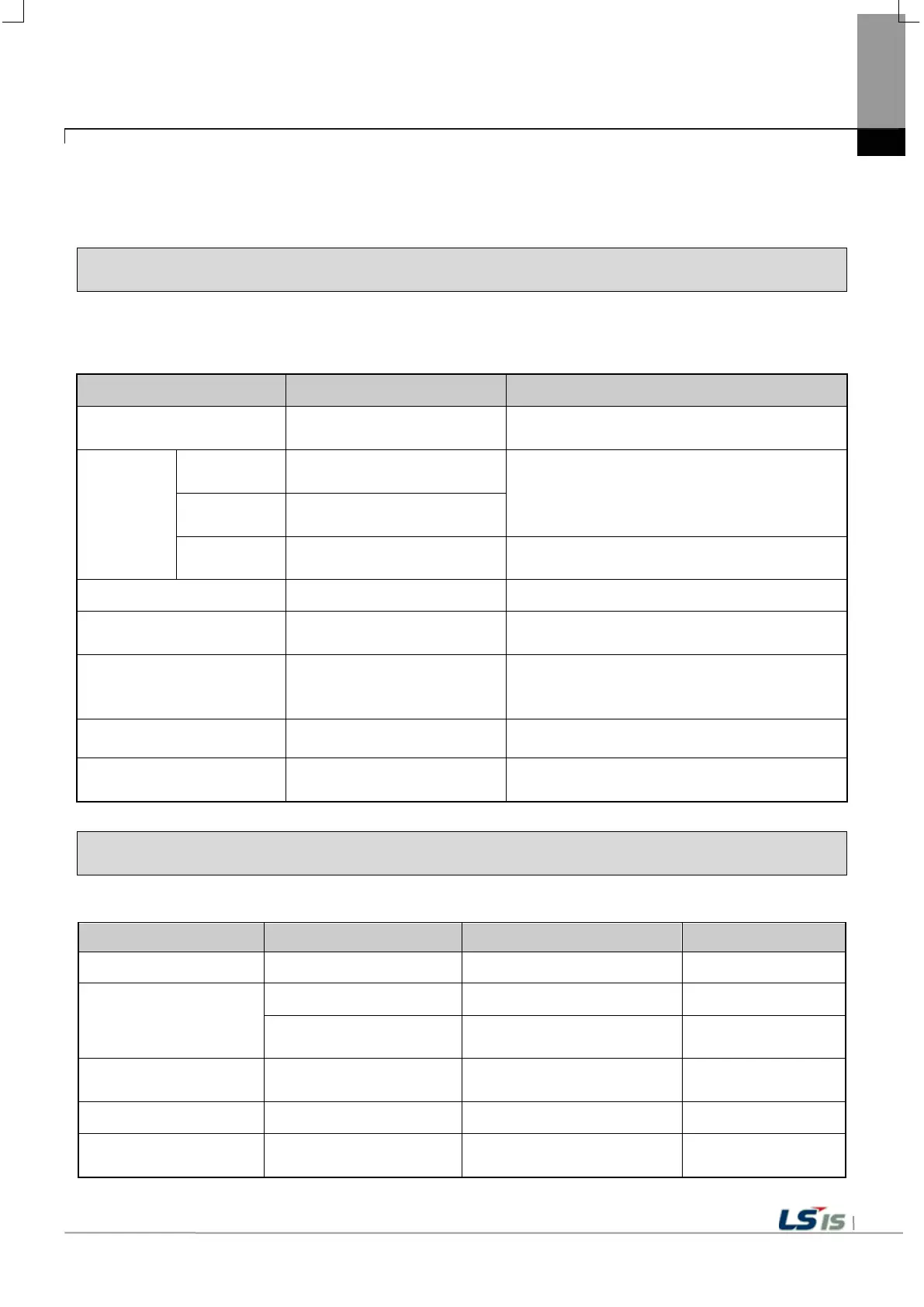

Maintenance category Maintenance contents Criterion Action

Mounting status Check the brackets Should be mounted firmly Retighten screws

Power terminal status

Loose terminal screws Not loose Retighten screws

Reduce the distance between

Keep the proper distance. Correction

Communication connector

status

Unwinding of fixed screw Not loose Retighten screws

Indication LED Check the lighting Blue LED should be turned on Refer to the Appendix 1.

Touch panel surface state Check the touch panel

No pollution such as water drops or

oil

Surface wiping

Loading...

Loading...