5-44 Published 7-23-2020, Control # 668-02

SET-UP AND INSTALLATION GRT9165 OPERATOR MANUAL

Dead-End Rigging/Wedge Sockets

Wedge socket assemblies are popular rigging accessories

used for decades to terminate hoist ropes on mobile cranes.

A wedge socket assembly is easily installed and dismantled,

but must be installed and used correctly. Use only a wedge

and socket of the correct size for the rope fitted. Failure to do

so may result in rope pulling through fitting.

Since state and local laws may vary, alternate attachment

methods may be necessary depending upon work

conditions. If alternate methods are selected, the user is

responsible and should proceed in compliance with the

regulations in force. If there are any questions, contact your

local Grove distributor or Manitowoc Crane Care

Do not mix components from different manufacturers. The

selection, installation, and use of a wedge socket assembly

must be in accordance with requirements of the wedge

socket manufacturer and hoist rope manufacturer upon

whose hoist rope the wedge socket assembly will be used.

Grove specifies size, type, class, and line pulls for hoist rope;

predominately rotation resistant hoist rope, and rigging

accessories such as overhaul balls and hook blocks for use

with each new crane it manufactures.

Other hoist ropes and rigging accessories are available from

various vendors. Different hoist rope manufacturers have

differing requirements for construction, handling, cutting,

seizing, installation, termination, inspection, and

replacement of hoist ropes they produce. Their advice

should be sought for each specific type of hoist rope a crane

user intends to install on a mobile crane.

When assembly is complete, raise boom to a working

position with a load suspended to firmly seat wedge and rope

in socket before crane is used operationally.

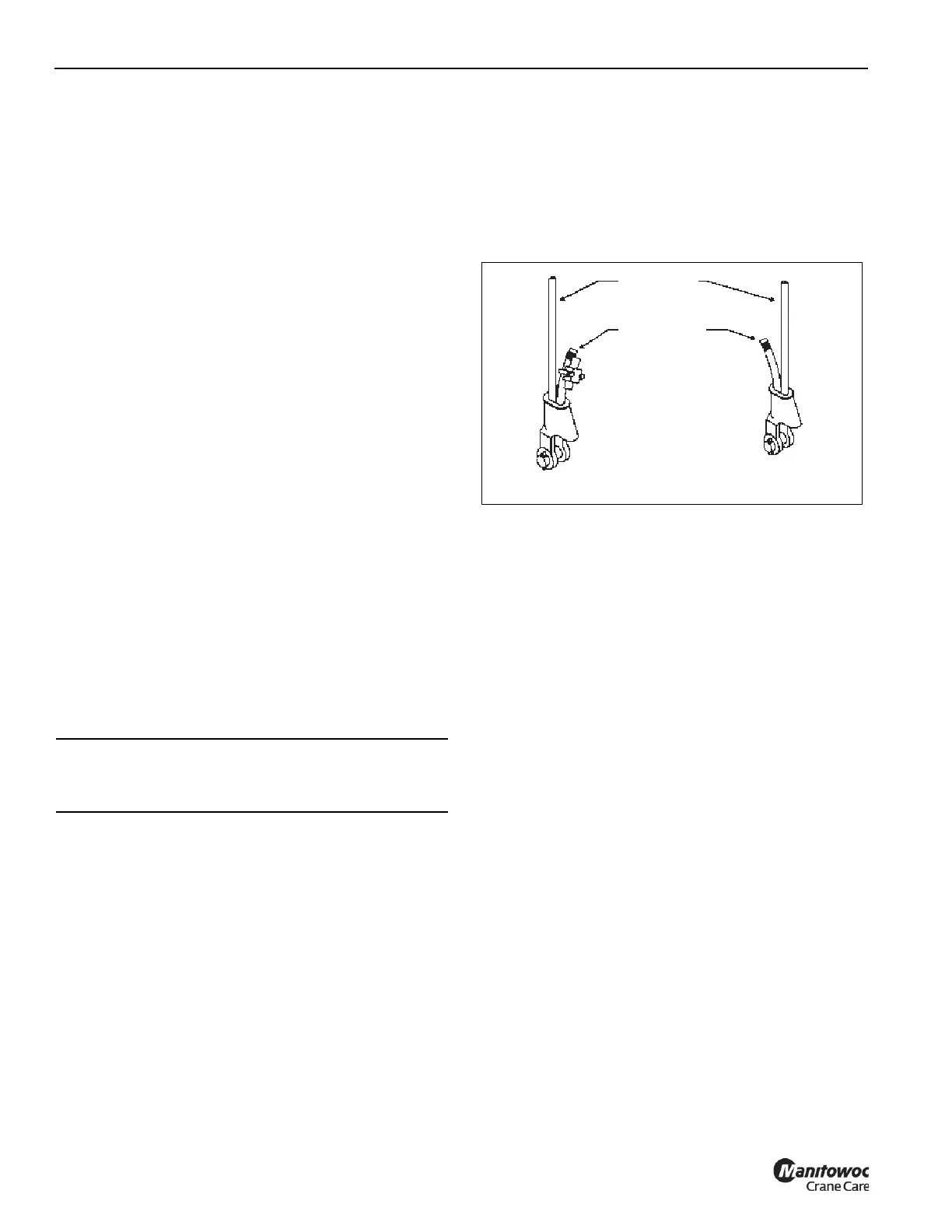

When anchoring socket to the boom, make sure flat face of

socket is toward boom sections.

Installing Wedge and Socket

1. Inspect wedge and socket. Remove rough edges and

burrs.

2. Seize hoist rope end using soft or annealed wire or

strand. If end of rope is welded, welded end should be

cut off unless otherwise stated by the rope manufacturer.

This allows distortion of the rope strands, caused by the

bend around the wedge, to adjust themselves at the end

of the line.

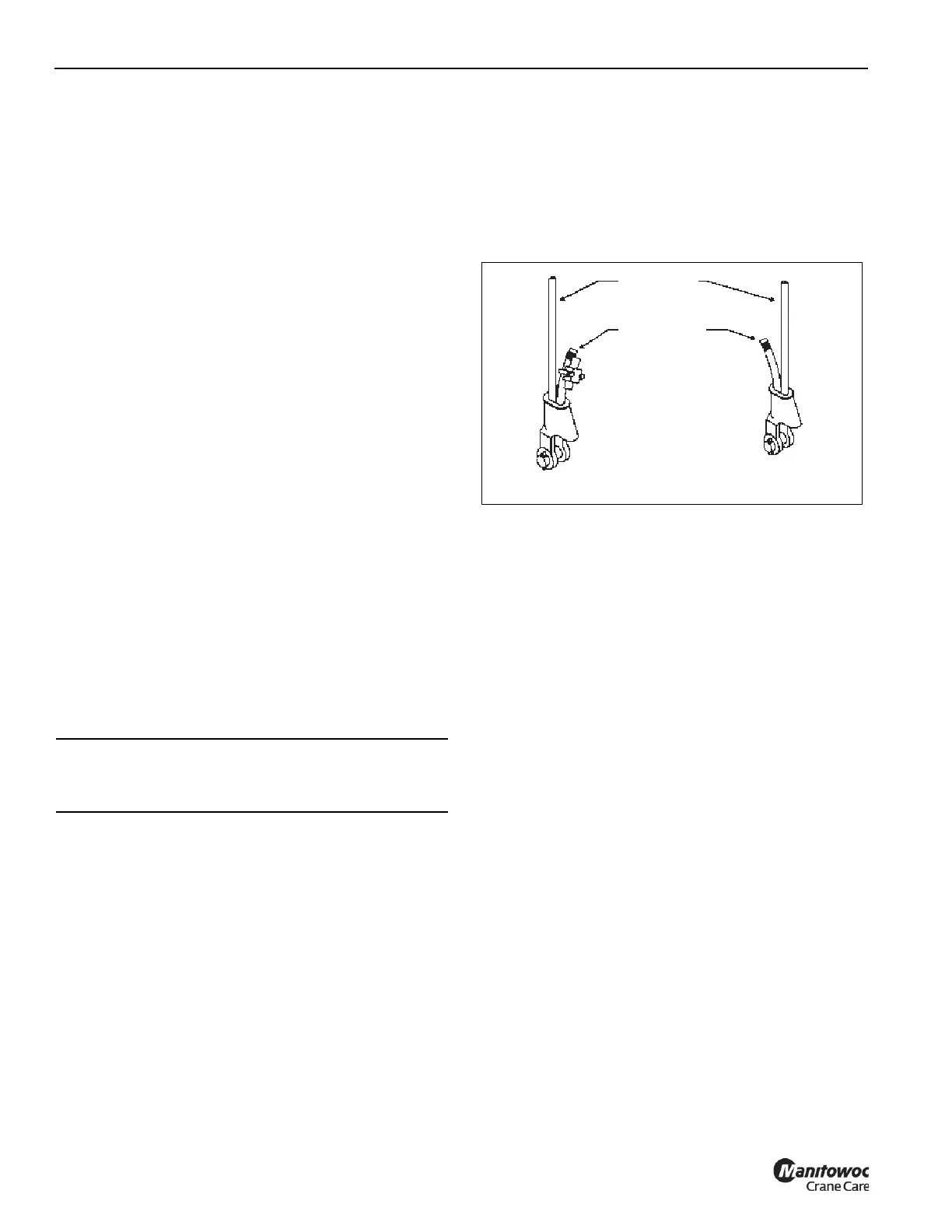

3. Make sure live end side (Figure 5-28) of rope is directly

in line with ears of socket and direction of pull to which

the rope will be subjected. If rope is loaded into socket

incorrectly, under a load the rope will bend as it leaves

the socket. The edge of the socket will wear into the rope

causing damage and eventual failure.

4. Insert hoist rope end in socket, form a loop in the rope,

and route rope back through socket allowing the “dead”

end to protrude from the socket. Make sure dead end of

the rope is long enough to apply end treatment after

wedge is seated.

5. Insert wedge in loop. Pull live end of rope until wedge

and rope are snug inside socket. It is recommended

wedge be seated inside socket to properly secure the

hoist rope using the crane’s hoist to first apply a light

load to the live line.

6. After final pin connections are made, increase loads

gradually until wedge is properly seated.

7. Wire rope and wedge must be properly secured inside

socket before placing crane into lifting service. It is the

wedge that secures the hoist rope inside the socket. The

dead-end treatment is used to keep wedge from

becoming dislodged from socket should the rope

suddenly become unloaded from the overhaul ball or

hook block striking the ground, etc.

Figure 5-29 shows methods for securing dead-ends of hoist

ropes in a wedge socket assembly. While the loop-back

method (C, D, E) is acceptable, take care to prevent the loop

becoming entangled with tree branches and other

components during crane transport, or the anti two-block

system and other components during crane operation.

CAUTION

If socket is not positioned with flat face toward boom

sections, structural damage will occur.

Incorrect

Correct

Dead End

Live End

5337

FIGURE 5-28

Loading...

Loading...