Manitowoc Published 04-06-18, Control # 231-14 4-7

MLC650 VPC-MAX™ OPERATOR MANUAL SET-UP AND INSTALLATION

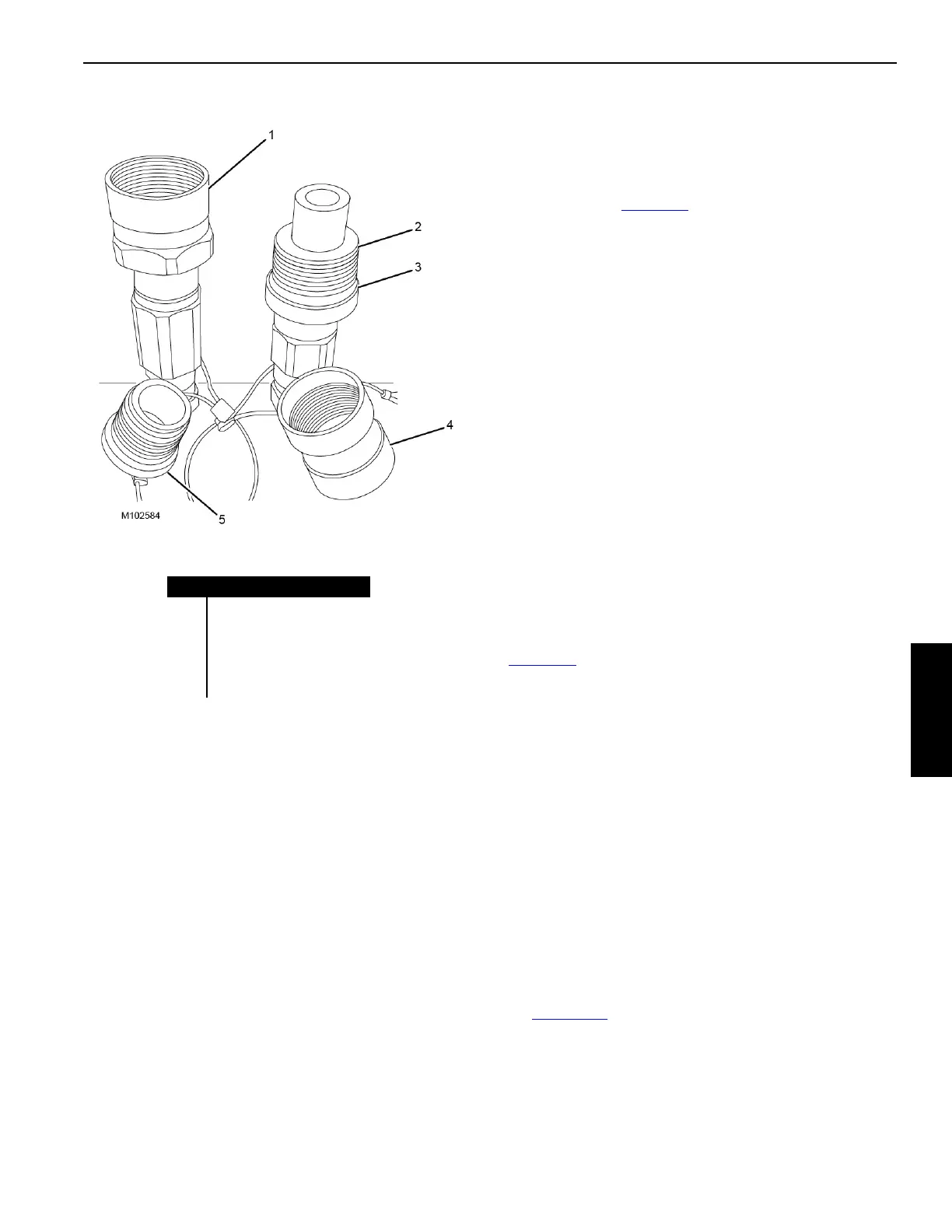

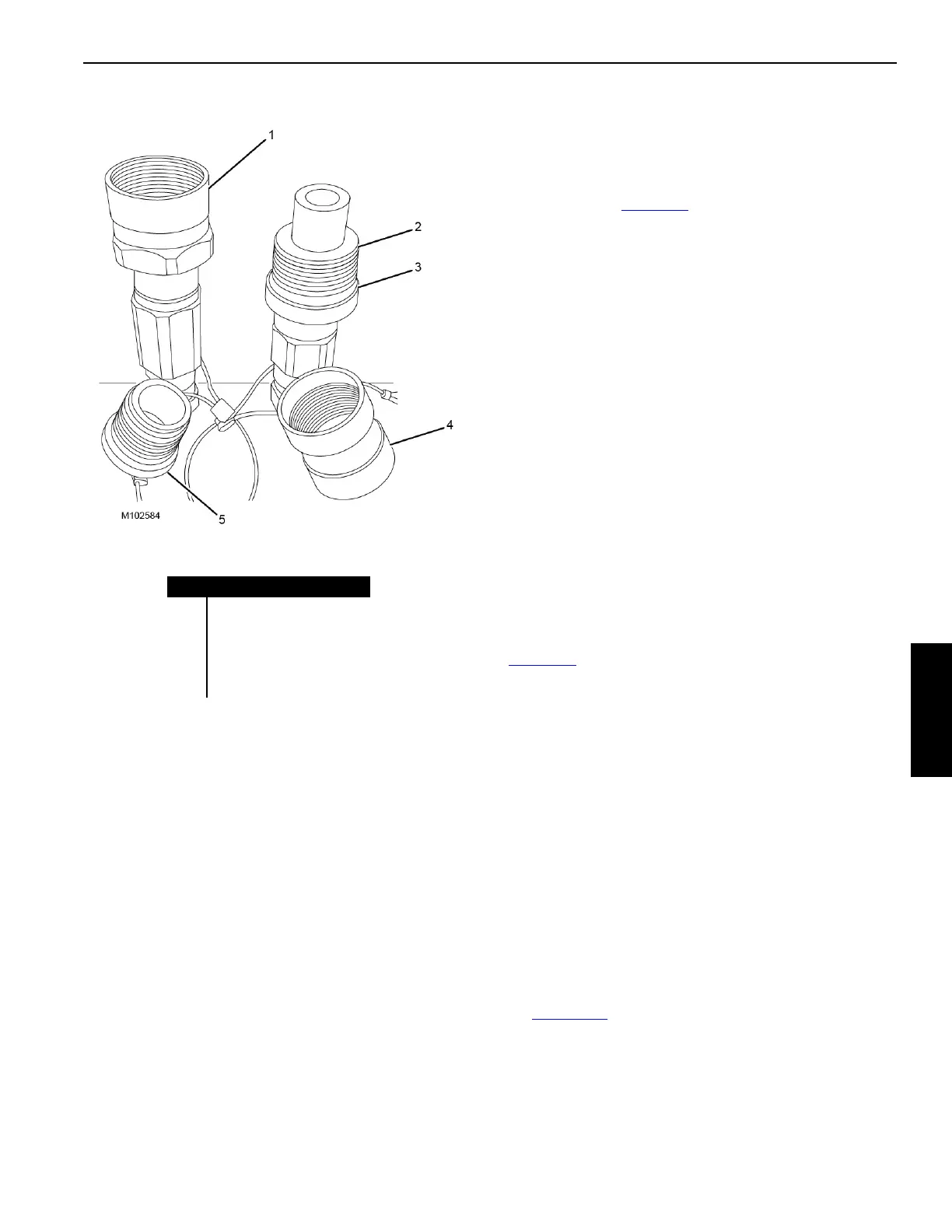

HYDRAULIC QUICK DISCONNECT

LUBRICATION

All hydraulic quick disconnects must be protected by

applying LPS-2 Aerosol Lubricant. Lubricant must be applied

while connecting and disconnecting the hydraulic quick

disconnects during crane assembly and disassembly.

1. All Quick Disconnects must be fully screwed together

until there is metal to metal contact during crane

assembly.

2. All plugs, regardless of location, must be fully screwed

together into their corresponding caps until there is

metal to metal contact during crane assembly.

Examples of locations of caps and plugs:

• Hanging lanyards

• Storage brackets

• Job box

3. All Quick Disconnects must be fully screwed together

with their corresponding cap and plug until there is metal

to metal contact during crane disassembly.

The following threaded areas of the quick disconnects, caps,

and plugs must be lubricated during crane assembly and

disassembly (see Figure 4-8

):

• Threaded surface of male quick disconnect

• Threaded surface of female quick disconnect

• Threaded surface of aluminum caps and plugs

• O-rings

NOTE: If the crane is stored without operating for long

duration, the hydraulic quick disconnects, caps,

and plugs must be lubricated every 6 months.

PIN AND CONNECTING HOLE

CLEANLINESS

To prevent dirt from damaging closely machined surfaces of

pins and connecting holes, perform the following tasks each

time the pins are installed:

• Thoroughly clean all pins and connecting holes.

• Apply a light coat of grease to all pins, contacting

surfaces, and connecting holes.

TIGHTENING HYDRAULIC COUPLERS

Connect each screw-to-connect coupler and nipple

(Figure 4-8

), as follows:

1. Lubricate coupler internal threads (1), nipple threads (2),

and nipple O-ring (3) with LPS-2 Aerosol Lubricant.

2. Hand tighten the coupler on the nipple.

3. Using opened-end wrenches from the parts box, tighten

the coupler until there is metal-to-metal contact between

the coupler and the nipple. Nipple o-ring must not be

visible.

To avoid damage, do not exceed a torque of:

• Size -06 = 2,2 Nm (1.62 lbf ft)

• Size -08 = 1,8 Nm (1.33 lbf ft)

• Size -12 = 5,6 Nm (4.13 lbf ft)

• Size -20 = 8,2 Nm (6.04 lbf ft)

• Size -24 = 26,0 Nm (19.16 lbf ft)

4. Check that the hydraulic tank shut-off valve (see

Figure 4-15

) is open.

Check for leaks after the crane has been operated with the

hydraulic oil at operating temperature. Retighten the

couplers if necessary.

Item Description

1 Female Quick Disconnect

2 Male Quick Disconnect

3O-ring

4 Aluminum Cap

5 Aluminum Plug

FIGURE 4-8

Loading...

Loading...