5-3

MAINTENANCE MA-5082-ENG B4 VS ADHESIVE MELTER MANUAL

Before disconnecting any hydraulic component or opening any distributor

outlet, the following steps must be performed:

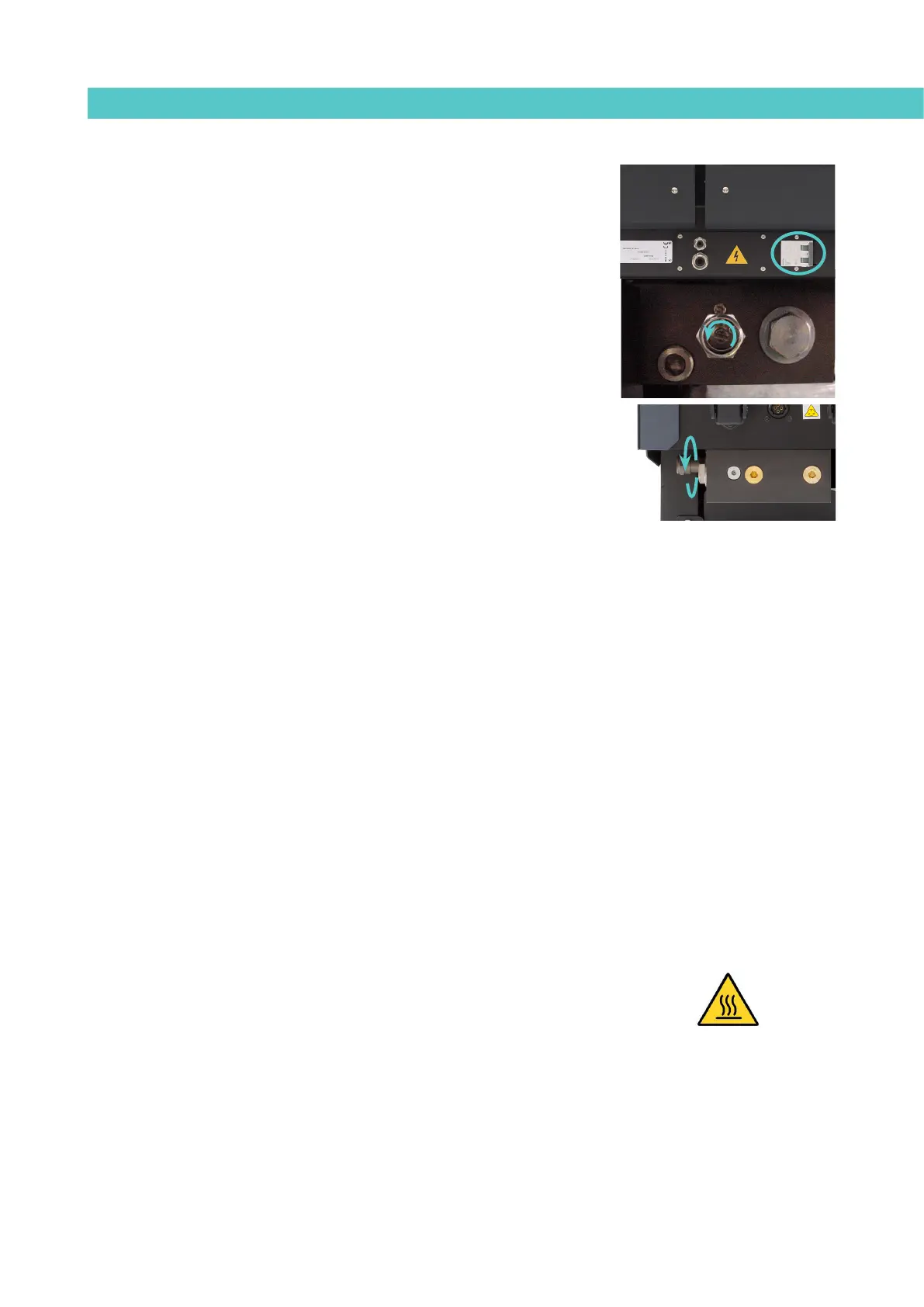

1. Disconnect the equipment’s power switch located on the side, next to

the power supply input.

2. Manually purge (or using the corresponding programmer control) the

applicator used.

3. Open the purge valve (in case of the equipment has one), located on

the distributor next to the filter turning it anti-clockwise. To do so, use

a slotted screwdriver. When the adhesive exits without pressure, close

the valve by turning it clockwise.

Cleaning the tank

Both the cylindrical hopper and hot-melt tank will need cleaning occasionally

to maintain their melting and anti-adherence properties. The tank interior is

covered in PTFE and sufficiently slanted to help the unloading of the hot-melt

adhesive and prevent it from remaining inside which would result in burning.

Also, when adhesives are mixed, reactions may occur between them, causing

degeneration and problems unloading to the pump.

It is therefore recommended that the tank is cleaned each time:

• A different hot-melt adhesive is used.

• Too much carbon deposit is generated inside.

Changing adhesive type

1. Use up as much of the adhesive as possible.

If you need to unload the adhesive before it has been used up, follow

the instructions in the section ‘Emptying the tank’.

2. Clean the remains of the hot-melt adhesive from inside the tank.

Warning: Use the appropriate protective equipment for high temperatures.

3. Add the appropriate type and quantity of the new adhesive, wait for it

to melt and pump at least one full tank through the system (hose and

applicator).

Cleaning burnt adhesive

1. Empty the tank directly (see the section ‘Emptying the tank’) to prevent

the burnt material from passing through the pump circuit.

Loading...

Loading...