5-5

MAINTENANCE MA-5082-ENG B4 VS ADHESIVE MELTER MANUAL

Filter maintenance

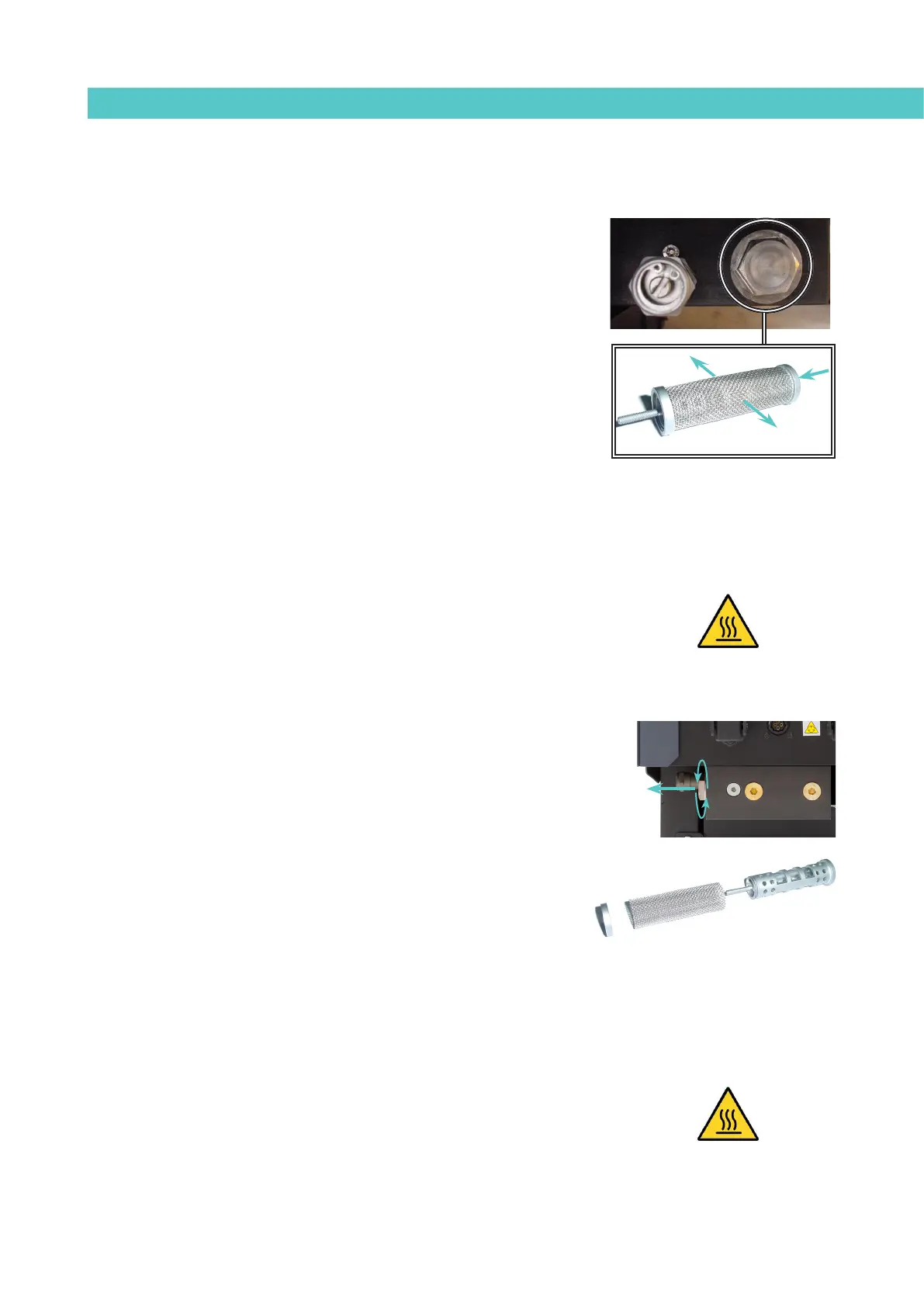

B4 VS melter equipment is equipped with a 100 mesh pump filter. The filter

prevents impurities and burnt adhesive remains from being pushed out from

the tank by the pump.

When the filter is removed from its housing, all the impurities remain inside

so that the inside of the distributor stays perfectly clean. The filter can be

cleaned or replaced with a new one.

No rule exists for determining when the filter should be changed. Several

factors influence this decision:

• The type and purity of the adhesives used.

• The working temperatures of the adhesive.

• Adhesive consumption in relation to the time in the tank.

• Changes to the type of adhesive used.

In any case, we recommend that the filter is checked and cleaned at least

every 1000 hours of operation (melter turned on).

Warning: Always wear protective gloves and safety glasses. Risk of burns.

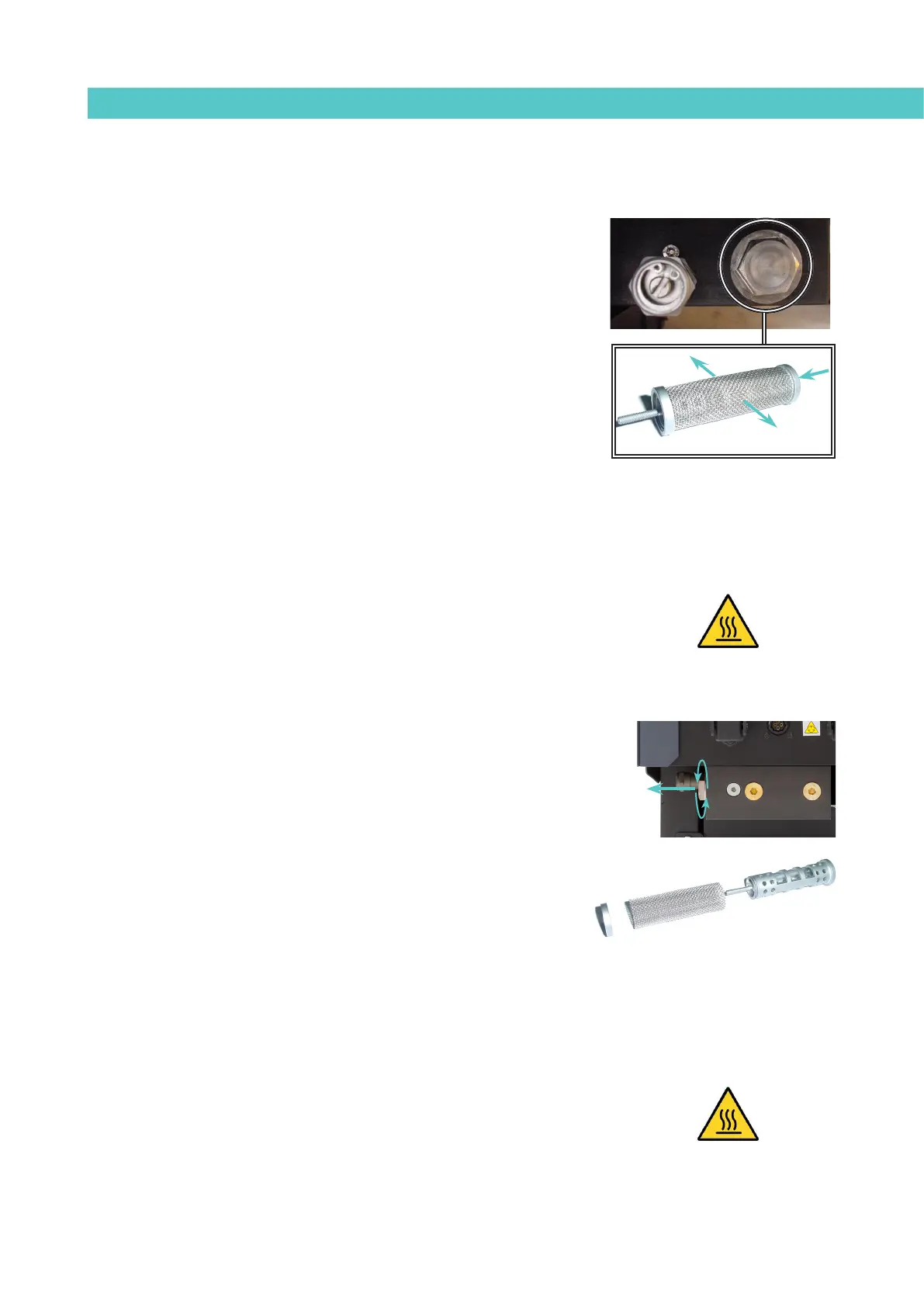

To change the filter:

1. Depressurise the system.

2. Using a 22 mm wrench, unscrew the hexagonal filter cap turning left

and remove it.

3. Unscrew the filter nut (1) and remove the mesh (2) from the filter body (3).

4. Depending on how dirty the mesh (2) is, clean or replace it, following

any waste regulations in force.

5. Screw the nut (1) back in place and place the filter inside the

distributor.

6. Replace the filter cap screw if damaged.

7. Screw the filter cap turning right and tighten as far as possible.

8. Continue to work as normal.

Warning: Use the appropriate protective equipment for high temperatures.

2

3

1

Loading...

Loading...