MA-5162-ENG MICRON

+

PISTON ADHESIVE MELTERMAINTENANCE

5-3

The depressurization valve releases the pressure from the hydraulic

circuit, returning the adhesive to the tank.

2. Purge all applicators that have been used either manually or with

the corresponding program command.

Access to pneumatic unit

To access the unit for more exhaustive machine maintenance, it will be

necessary to remove the electrical cabinet from its place so it can be handled

more comfortably and accessibly. To do this, slacken the 1/4 turn screw that

keeps the electrical cabinet in position (screw A) and slide it along the guides.

To carry out this operation it is not necessary to open the electrical cabinet

door.

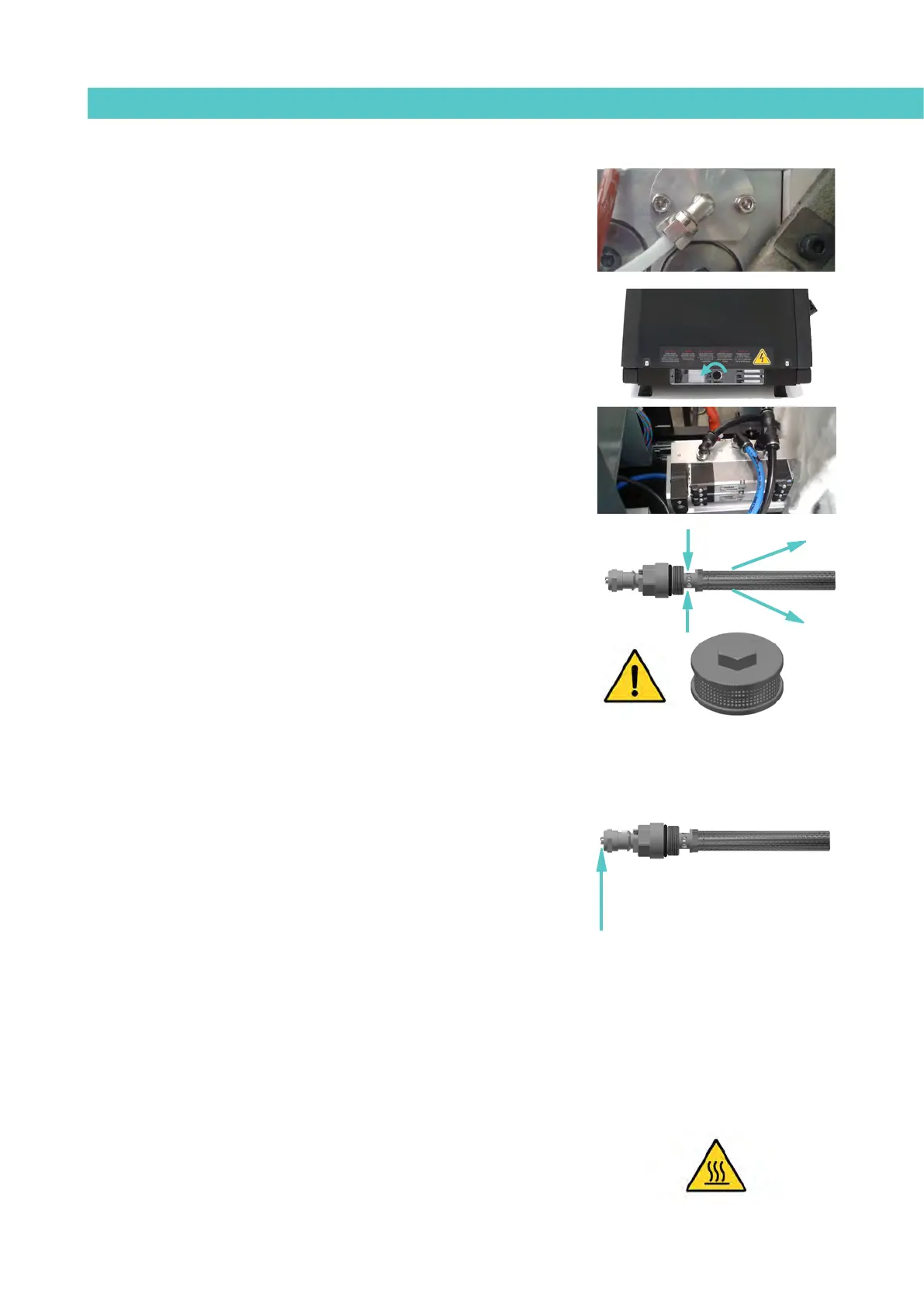

Filter maintenance

‘MICRON+’ series melter equipment is equipped with a 50 mesh pump filter.

The filter prevents impurities and burnt adhesive remains from being pushed

out from the tank by the pump.

Warning: It is a good idea to also use a filter in the tank intake valve. This

filter performs a first-step filtration, preventing impurities resulting from

burning in the tank and other impurities that may enter from the outside from

passing through.

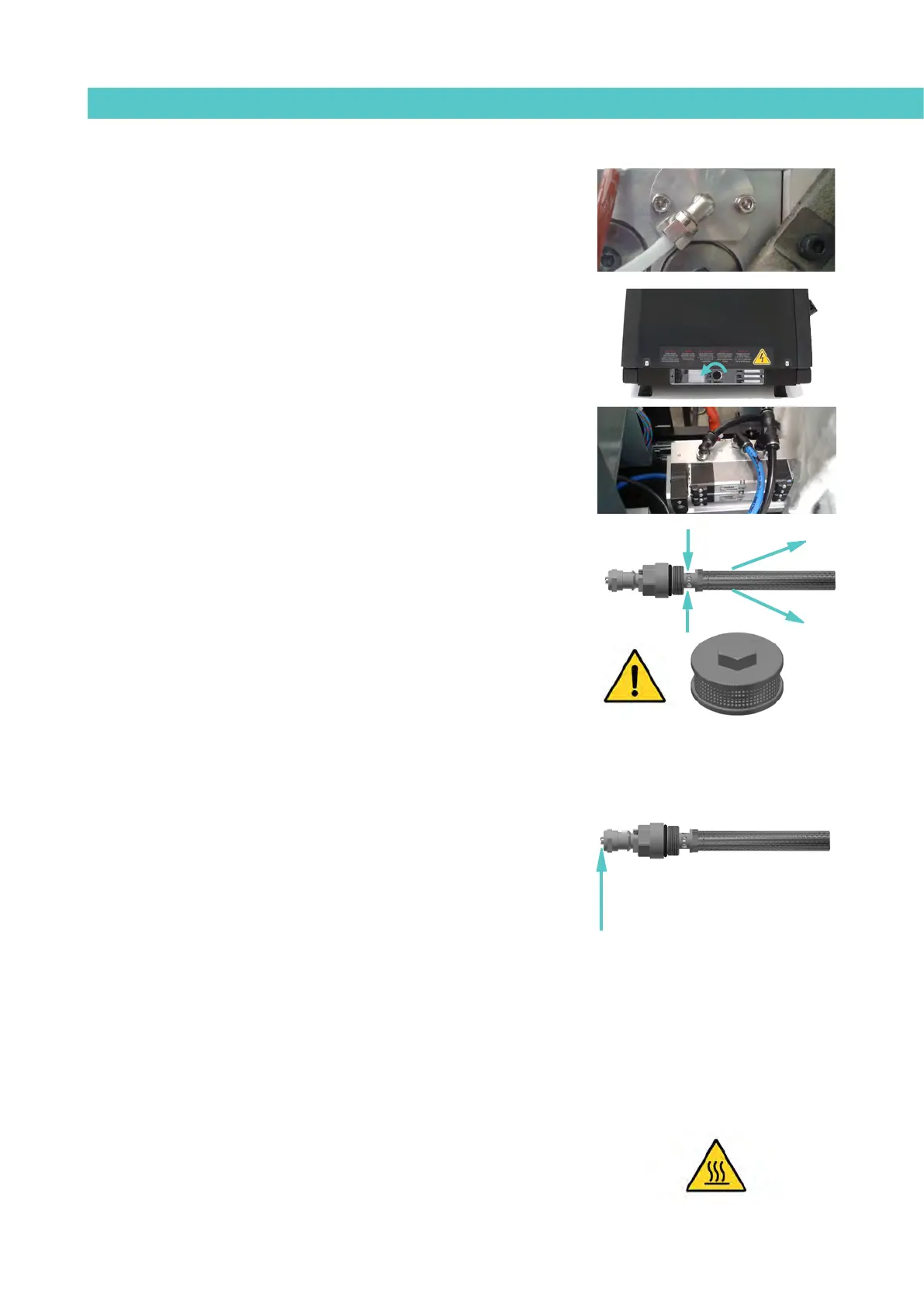

The adhesive flows from the inside to the outside of the filter, with impurities

being trapped inside it.

The drain valve is included in the filter cap.

When the filter is removed from its housing, all the impurities remain trapped

inside, and the inside of the distributor stays perfectly clean. The filter may be

cleaned or replaced directly with a new one.

No rule exists for determining when to change the filter. Several factors

influence this decision:

• the type and purity of the adhesives used.

• the adhesive work temperatures.

• adhesive consumption relating to the time it normally remains into the

tank.

• changes in the type of adhesive used.

In any case, we recommend checking and cleaning the filter at least every

1000 hours of operation (melter equipment turned on).

Warning: Always use protective gloves and goggles. Risk of burns.

purge zone

Loading...

Loading...