FOCKE MELER GLUING SOLUTIONS

5-4

MAINTENANCE

To change the filter, it should be borne in mind that the filter and purge valve

are the same assembly:

1. Depressurise the system.

2. To remove the whole filter, unscrew the assembly’s hexagonal plug

using a 22mm socket driver and remove it.

3. Depending on the amount of dirt inside the cartridge, clean it or throw

it away, following the applicable waste regulations.

4. Replace the joints if they are damaged.

5. Screw the assembly up again, clockwise.

6. Put the assembly back inside the distributor and tighten the screws.

7. Continue to work as normal.

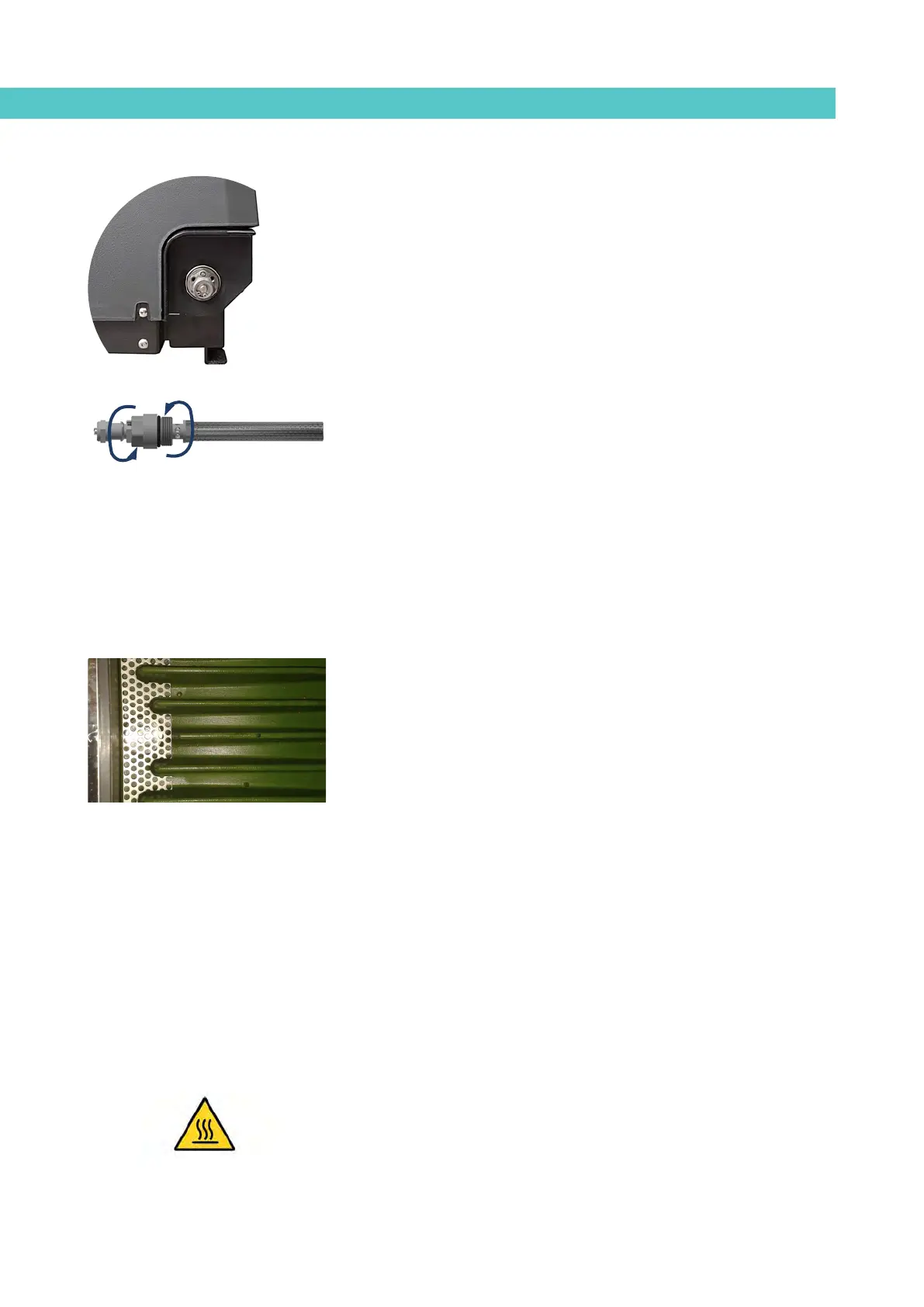

Cleaning the tank

The hot-melt tank must be cleaned on occasion to maintain its fusion and

anti-adherence properties. The tank is covered on the inside with PTFE and

inclined enough to aid unloading the hot-melt and to avoid it from being

retained inside when consequential burning occurs.

Furthermore, when adhesives are mixed, reactions may occur between them,

causing a degeneration and thus problems in unloading in the direction of the

pump.

Therefore, it is recommended to clean the deposit every time that:

• a change is made to a different type of hot-melt.

• too much burnt material is generated in its interior.

Changing adhesive type.

1. Use up as much of the adhesive as possible.

If it is necessary to unload the adhesive without having used it up as

much as possible, follow the instructions in the section ‘Emptying the

tank’.

2. Clean the remains of hot-melt adhesive on the inside of the tank.

Warning: Use appropriate protective equipment for high temperatures.

3. Add the appropriate type and quantity of the new adhesive, wait for it

to melt and pump at least one full tank through the system (hoses and

applicators).

Loading...

Loading...