MA-5162-ENG MICRON

+

PISTON ADHESIVE MELTERMAINTENANCE

5-5

Cleaning burnt adhesive

1. Empty the tank directly (see the section ‘Emptying the tank’) to prevent

the burnt material from passing through the pump circuit.

2. Clean the adhesive remains and burnt material inside the tank. Do not

use sharp objects that might damage the inside coating.

Warning: Use appropriate protective equipment for high temperatures.

3. Add the appropriate type and quantity of adhesive and wait for it to

melt.

4. Remove the filter cartridge and clean it, if necessary (see the section

‘Filter maintenance’).

5. Reassemble the filter without the cartridge.

6. Pump a minimum of one tank through the distributor output marked

number 1.

7. Remove the filter and attach it to the corresponding cartridge. Reinstall

it in the distributor.

8. Refill the tank with adhesive, wait for it to melt and continue working

as usual.

Warning: Whenever you handle the filter or any other element subject to

pressure, you must always perform a system depressurization first (see the

corresponding section)

Emptying the tank

During normal maintenance activities, it is recommended, and sometimes

necessary to empty the tank directly, without passing the adhesive through the

pump system.

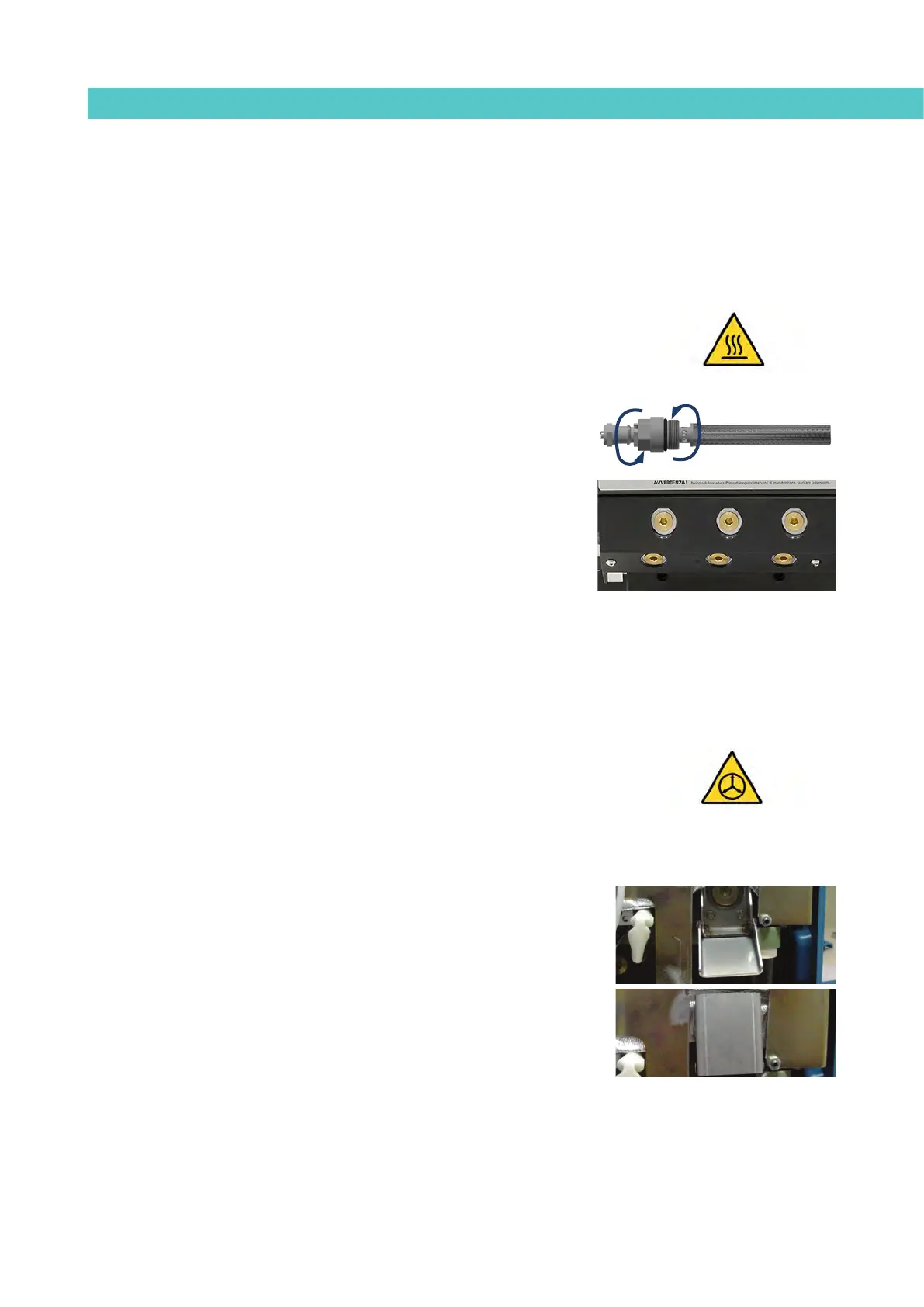

In the case of the MICRON+ 5, the tank does not have a pouring chute so, to

empty out the adhesive you need to wait until it has cooled and separate it

from the walls of the tank, making it easier to remove.

For the other models, empty the tank following these indications:

1. Keep the tank at working temperature.

2. Remove the tank cover and then its casing.

3. Lower the emptying chute attached to the tank and put a suitable

container in position.

1

Loading...

Loading...