Section 5 - Maintenance

Page 122 90-866938081 MAY 2009

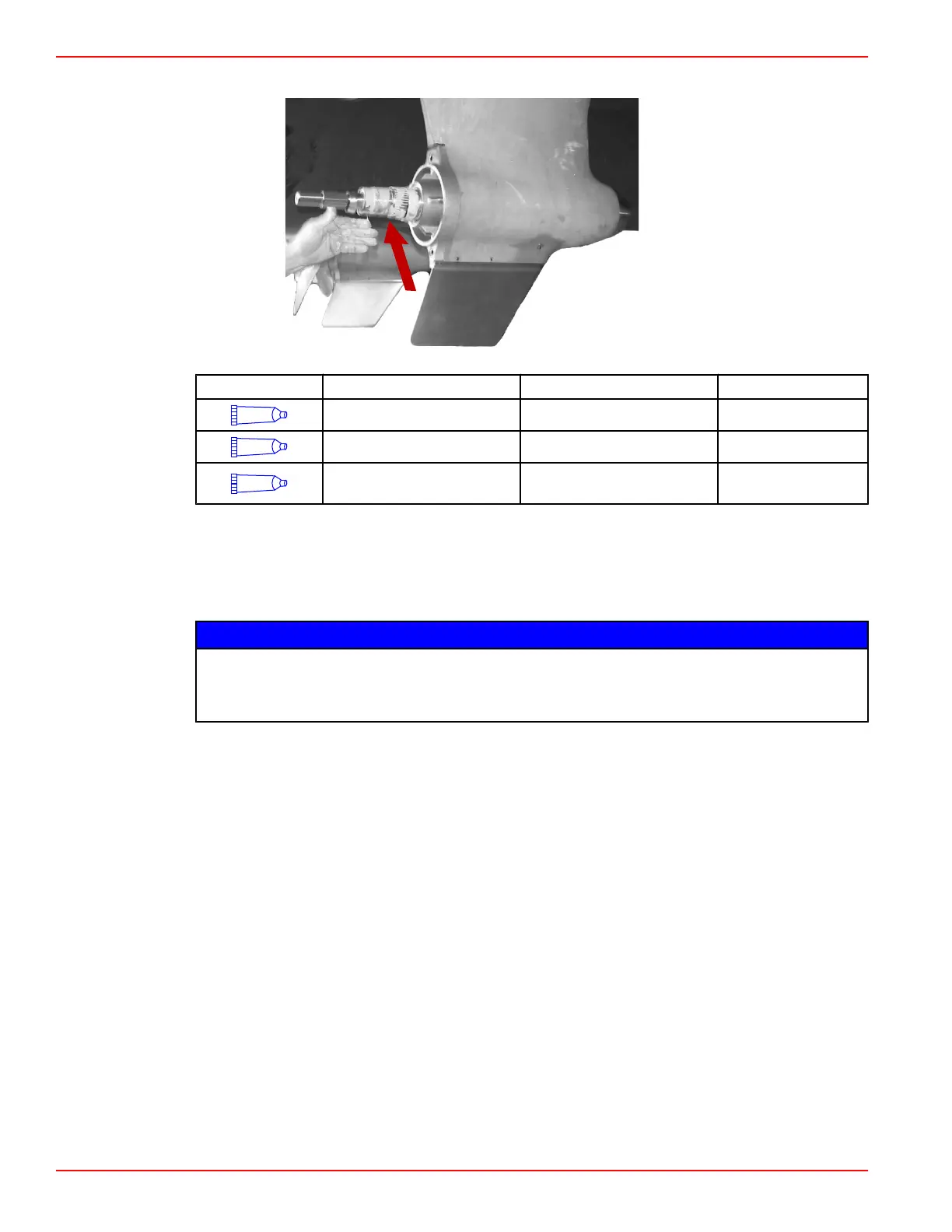

2. Apply a liberal coat of one of the following lubricants to the propeller shafts.

Tube Ref No. Description Where Used Part No.

94

Anti-Corrosion Grease Propeller shafts 92-802867Q 1

34

Special Lubricant 101 Propeller shaft 92-802865Q02

95

2-4-C Marine Lubricant with

Teflon

Propeller shaft 92-802859A 1

3. Install the propellers. Refer to Propellers.

Corrosion and Corrosion Protection

The Causes of Corrosion

NOTICE

Washing the MerCathode assembly can damage components and lead to rapid

corrosion. Do not use any cleaning equipment such as brushes or high‑pressure washers

to clean the MerCathode assembly.

Whenever two or more dissimilar metals (like those found on the drive) are submerged in

a conductive solution, such as saltwater, polluted water, or water with a high mineral

content, a chemical reaction takes place causing electrical current to flow between

metals. The electrical current flow causes the metal that is most chemically active, or

anodic, to erode. This is known as galvanic corrosion and, if not controlled, it will in time

cause the need for replacement of power package components exposed to water. Refer

to the Marine Corrosion Protection Guide (90‑88181301).

Corrosion Protection

These power packages have anodes as standard equipment to help protect them from

galvanic corrosion under moderate conditions.

The MerCathode System and sacrificial anodes will provide corrosion protection under

normal usage. However, boats connected to AC shore power require additional protection

to prevent destructive low‑voltage galvanic currents from passing through the shore‑power

ground wire. A Quicksilver Galvanic Isolator can be installed to block the passage of these

currents while providing a path to ground for dangerous fault (shock) currents. Refer to the

Diesel Parts and Accessories Guide

(90‑892645008) or the

Mercury Accessories Guide

(90‑420000009) for part numbers.

IMPORTANT: If AC shore power is not isolated from boat ground, the MerCathode System

and anodes may be unable to handle the increased galvanic corrosion potential.

Loading...

Loading...