MevaLite

ML-41

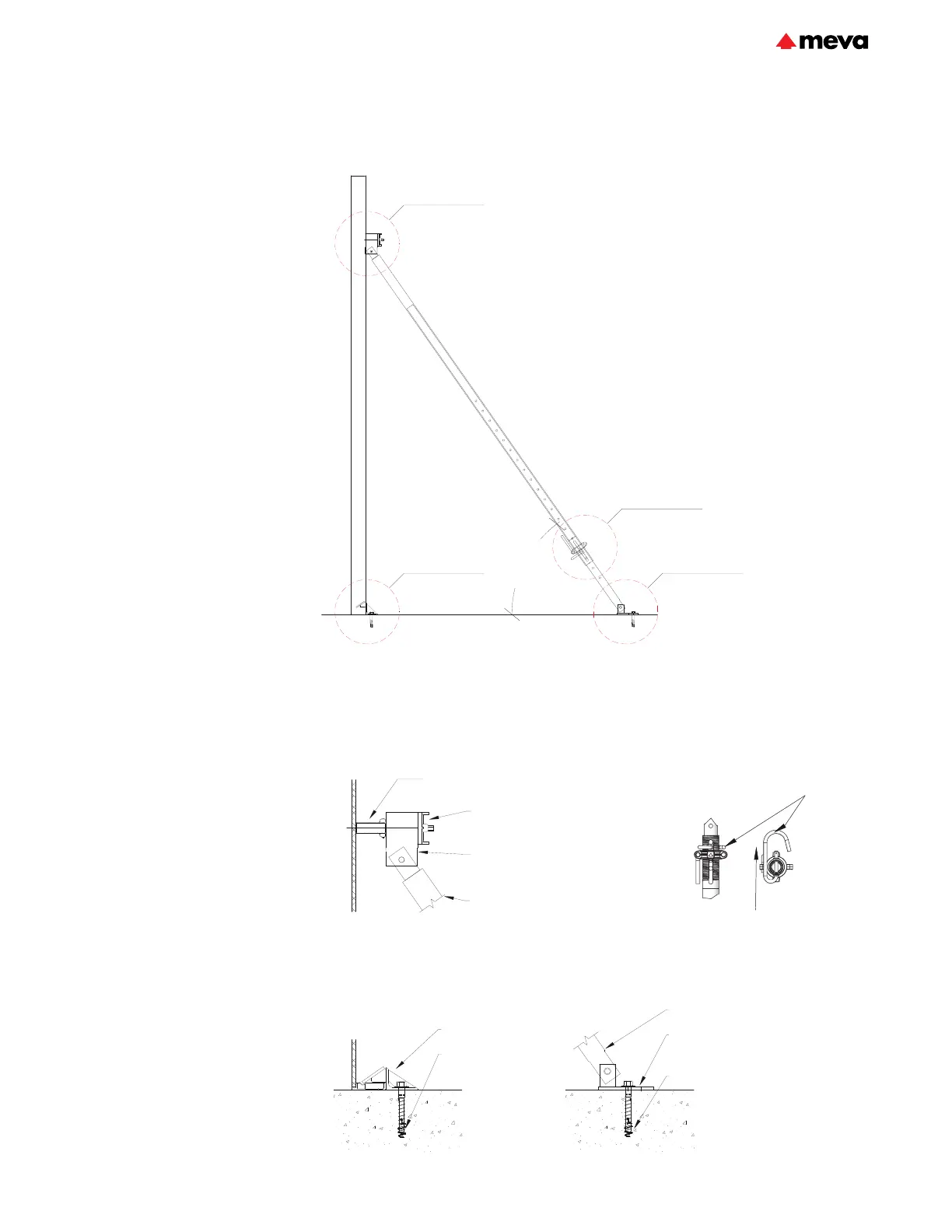

Wall Braces

Wall braces and accessories are

available for plumbing and aligning

the formwork (Fig.41.1). If braces

are used to resist wind or other

loads, the bracing system and

anchorages must be designed by

a competent person in accordance

with all applicable governmental

regulations, codes, and ordinances.

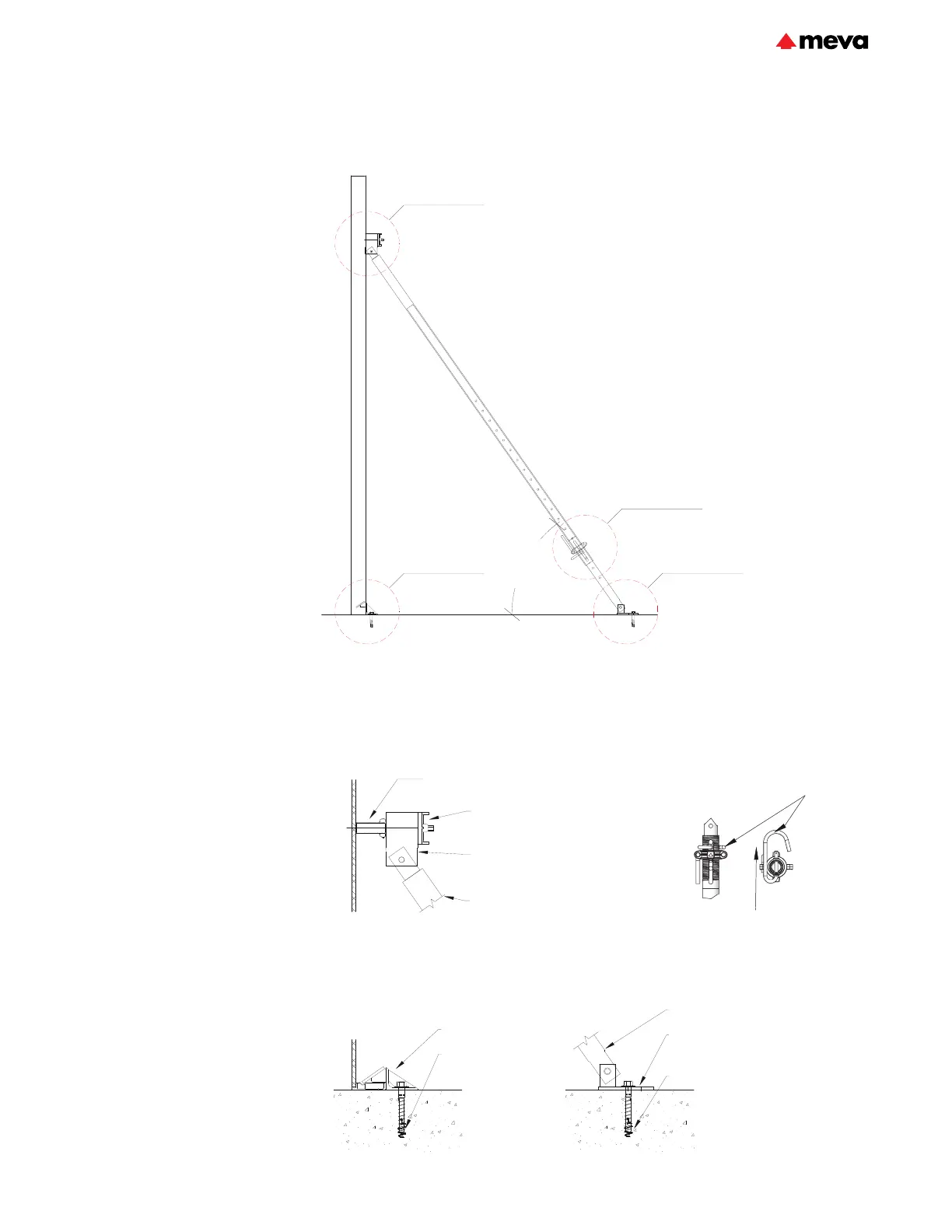

Wall braces are attached to the

panels at the multi-function

profiles using formwork prop

connectors and flange screws

(Fig.41.2). Shoe plates must

be installed and anchored at

the bottom of the formwork

(Fig.41.4). The allowable uplift

on the shoe plate is 2000lb when

properly anchored. The base of

the brace is anchored using the

articulated foot plate (Fig.41.5).

If adequate foundations are not

present to resist the required loads,

temporary footings or deadmen

will be needed.

Formwork must be kept stable at

all times. Each individual wall form

section must be supported by at

least two braces.

Note:

When installing R160 and/or

R250 make sure the inner tube is

attached at the formwork prop

connector.

Always ensure G-hook is properly

engaged on props prior to

releasing gangs from crane

(Fig.41.3).

Fig. 41.1

Fig. 41.2

Fig.41.2

Multi-function profile

60° max.

Flange screw 18

Formwork prop connector with

head bolt & cotter pin

Brace

Fig. 41.4 Fig. 41.5

Shoe plate 23

3/4" diameter

anchor

Brace

Articulated foot plate with

bolt & cotter pin

3/4" diameter anchor

Fig.41.4 Fig.41.5

Fig.41.3

Fig. 41.3

G-hook

engaged

Wall formwork

Technical Instruction Manual / June 2022

Loading...

Loading...