ML-46

MevaLite

Gang Forming

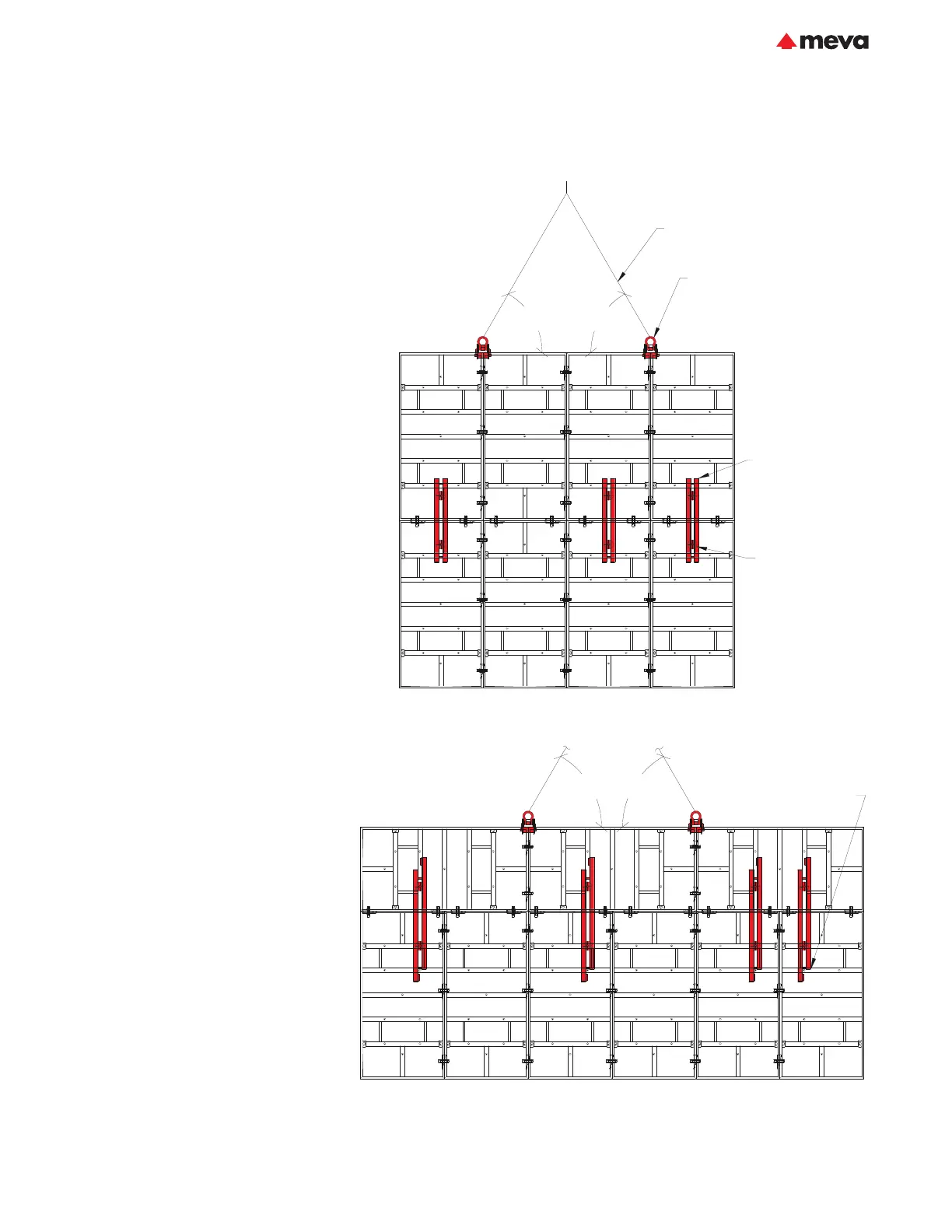

Each crane hook must be attached

at a panel joint (Fig.46.1) or above

a stiffener or panel joint when

the top panels are horizontal. The

number and location of crane

hooks and the rigging arrangement

must be established by the user so

that no individual component is

overloaded. Spreader beams with

load equalizers are recommended

for all but simple two-point lifts.

Vertical steel rails must be installed

across stacked panel joints for

lifting gang forms. The following

rules must be observed:

1. Maximum average rail spacing

is 6'. Rails should be installed on

panels at both ends of each gang.

2. Gangs up to 13' high may use

3' long rails on vertical panels

with (1) flange screw on each side

of the panel joint connected to

the threaded hole in the vertical

end cross member of the panel

(Fig.46.1).

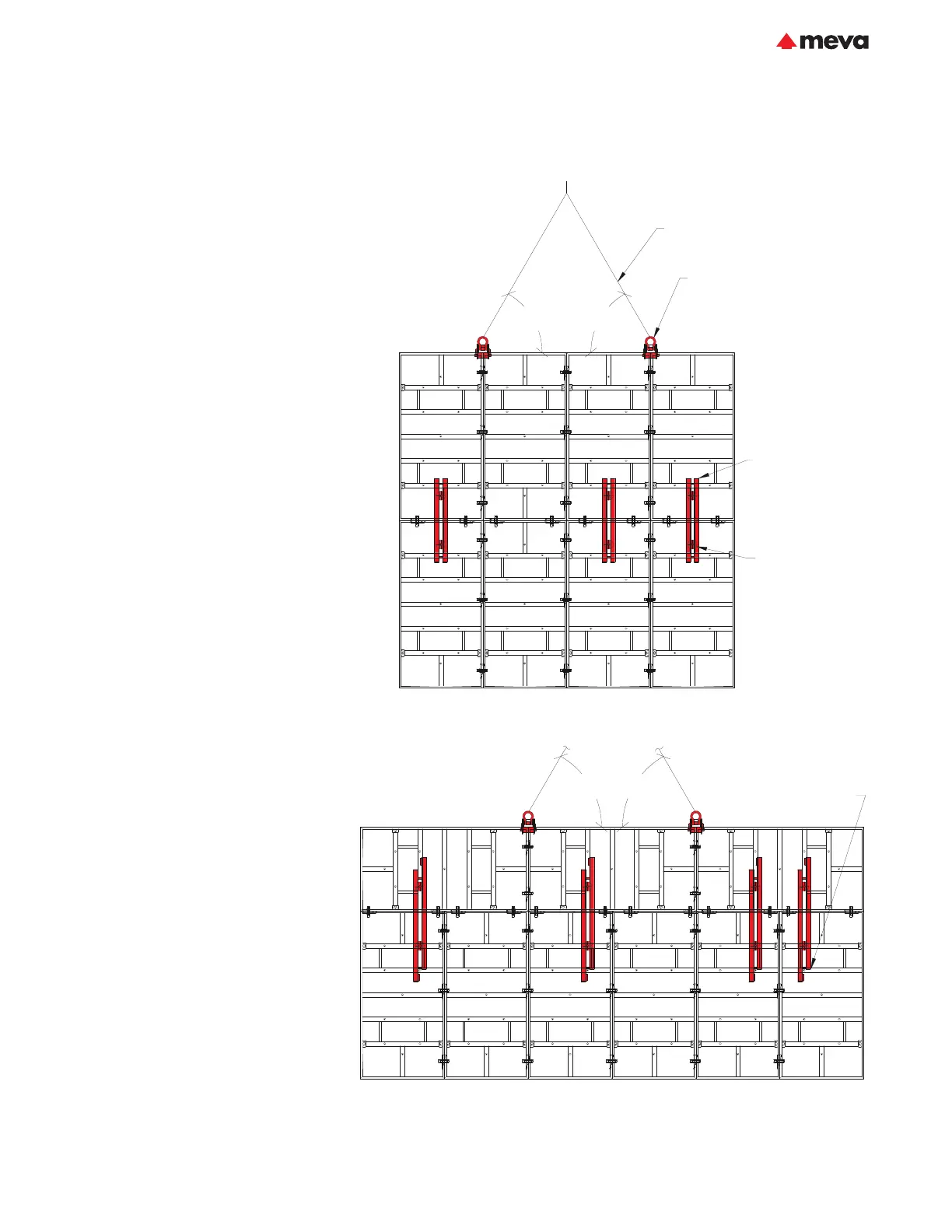

3. Gangs with horizontal panels

require rails that extend to the next

cross member beyond the flange

screw connection of the vertical

panel (Fig.46.2).

4. Gangs over 13' high require

6' rails or longer. Flange screw

connections must be at least

101/2" away from the panel joint,

and rails must extend to the next

cross member beyond the flange

screw connection (Fig.47.1).

Horizontal panels <3' wide may

only be located at the top or

bottom of the gang.

5. Maximum gang height for

single lift is 18'. Higher walls must

be set in multiple lifts, unless

special analysis and design are

performed.

Fig. 46.2 Gang form with horizontal top panels

Rigging (by others), typ.

60° min.

Flange screw 18, typ.

Crane-hook, typ.

Steel rail, typ.

6 x 3 6 x 36 x 3 6 x 3

6 x 3 6 x 3 6 x 3 6 x 3

Rails must extend to next

cross member beyond

flange screw connection

Fig. 46.1 Typical gang form

6 x 3 6 x 36 x 3 6 x 3

R 3'

R 3'

R 3'

60° min.

6 x 3 6 x 3

6 x 3

6 x 3

6 x 3

R 4'

R 4'

R 4'

R 4'

60° min.

60° min.

Wall formwork

Technical Instruction Manual / June 2022

Loading...

Loading...