MevaLite

ML-49

Assembly, Erection and Stripping

Planning Stage

Planning and preparation are the

keys to a successful application of

any formwork system.

To determine the amount of

formwork material that will be

needed, a number of influencing

factors should be taken into account

such as:

Æ movement of formwork on the

site, including weight to be handled

and capacity of lifting equipment

Æ project schedule

Æ construction joints (if specified)

that define concrete placements

Æ pour plan & sequence, taking

into account the number of corners,

pilasters, etc. in each pour

Æ stripping requirements

Æ concrete placement method

Æ reinforcing steel placement

method

Æ site conditions and accessibility

Æ coordination with other trades

Once all these aspects have

been considered, the quantity of

formwork can be determined.

During the planning stage some

general aspects of the forming

details should also be considered,

such as incorporating stripping relief.

Continuous formwork between two

structural elements such as walls

or pilasters should utilize stripping

corners, pilaster panels, or job built

fillers to facilitate stripping.

A safety plan should be developed

to address all aspects of the

formwork operation including

assembly, erection, concrete

placement, and stripping. Adequate

fall protection must be provided as

required by all applicable regulations

& codes.

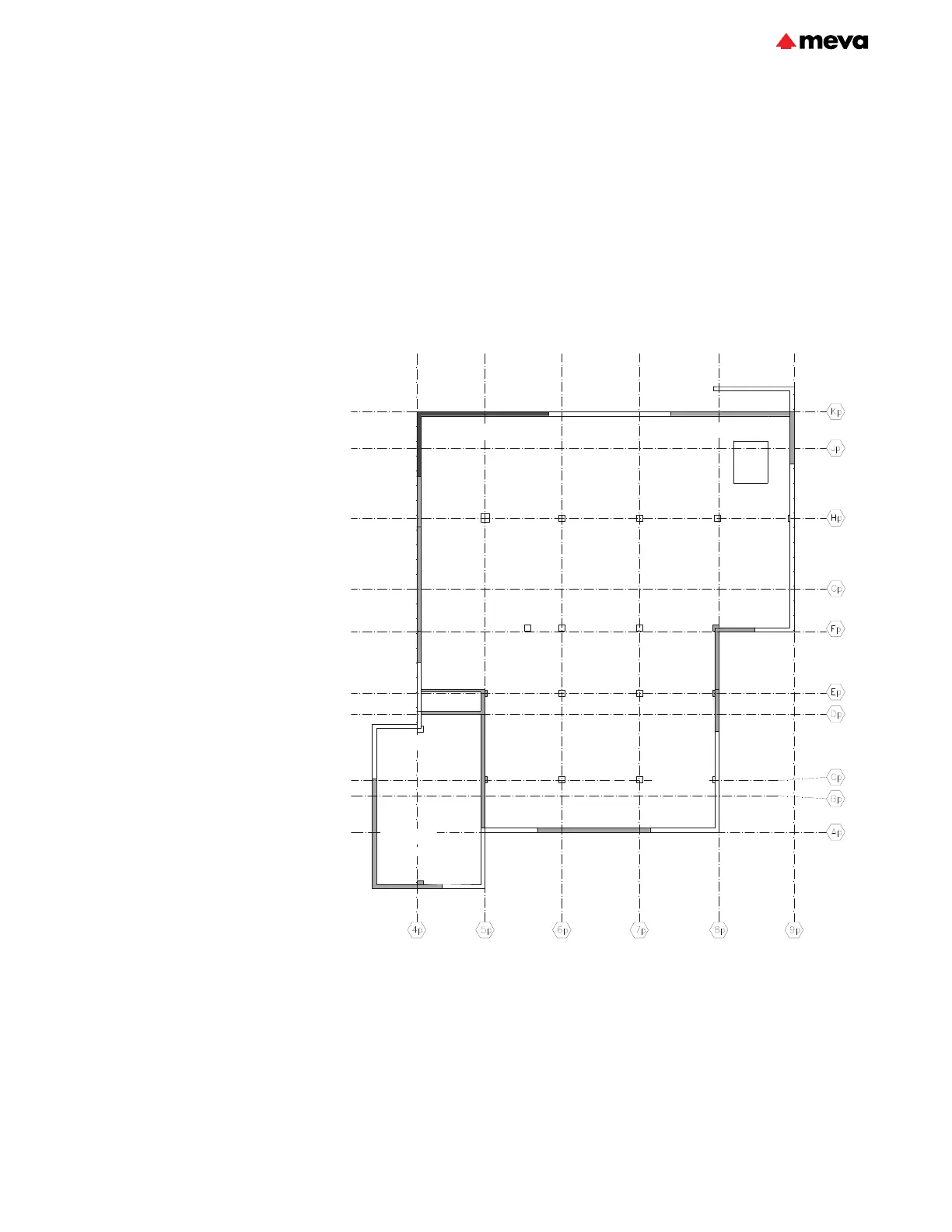

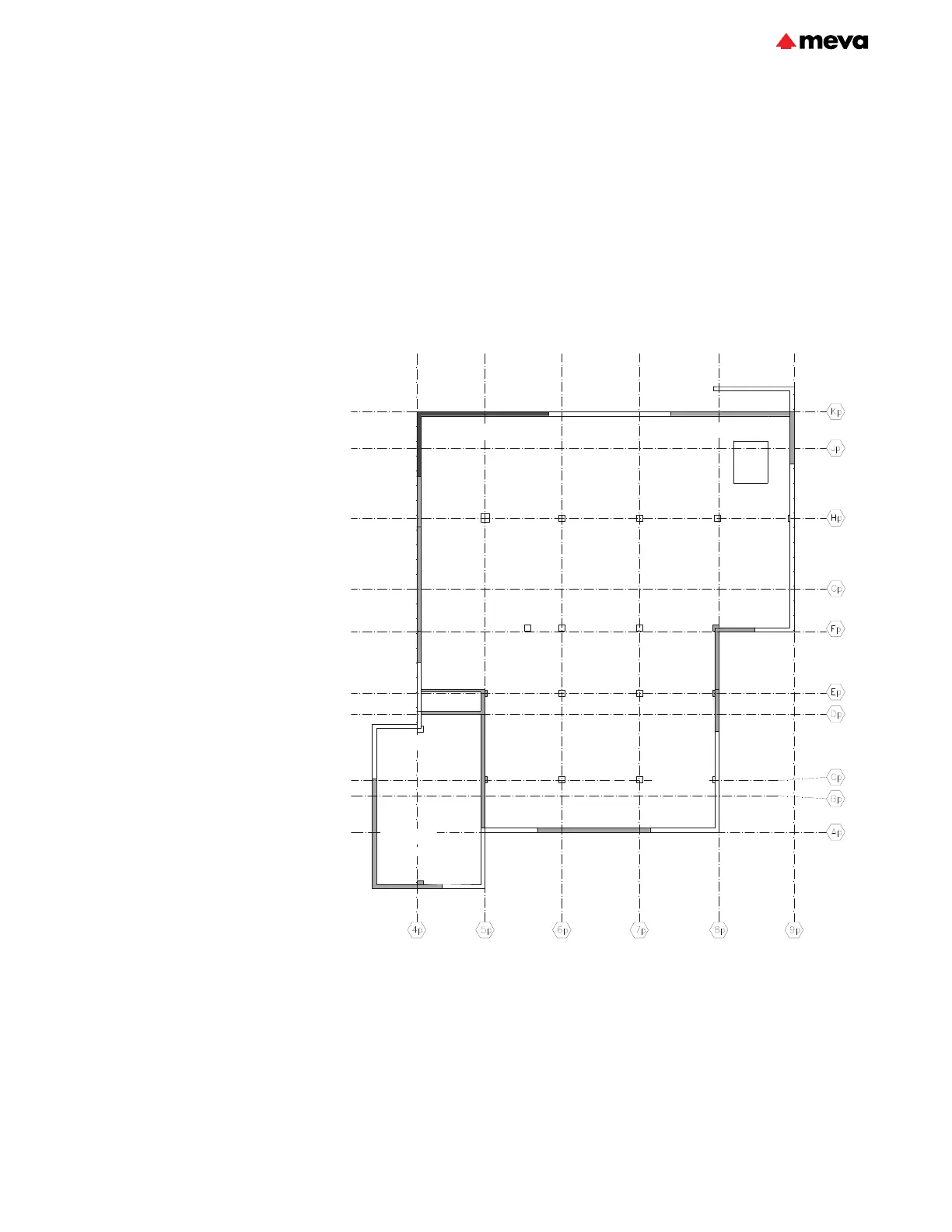

Fig. 49.1 Example wall pour plan

Pour #1Pour #2 Pour #3

Pour #4

Pour #5

Pour #6

Pour #7

Pour #8

Pour #9

Pour #10

Pour #11

Pour #12

Wall formwork

Technical Instruction Manual / June 2022

Loading...

Loading...