SECTION I

GENERAL INFORMATION

© Midmark Corporation 2002 SF-1803 Page 1- 6 Printed in U.S.A.

Recommended Circuit:

A separate (dedicated) circuit is recommended for the

sterilizer. Sterilizer should not

be connected to an elec-

trical circuit with other appliances or equipment unless

circuit is rated for the additional load.

Chamber Pressure:

Operating..................................27-31 psi (186-215 kPa)

Maximum Before Safety

Valve Opens....................................... 40 PSI [+/- 2PSI]

(275.8 kPa)

Chamber Temperature:

Operating.............................230 - 275° F (110 - 135° C)

Certification: ASME Boiler & Pressure Vessel Code

1.4 Ordering Parts

Contact Midmark’s Technical Service Department with

all necessary information (model / serial number, part

number, quantity, etc.).

Orders can be placed using the Fax Order Form (page

7-2) or by calling the phone number on the back cover

of this manual.

1.5 Special Tools

Table 1-3 lists all special tools needed to repair the

sterilizer, how to obtain the tools, and purpose of each.

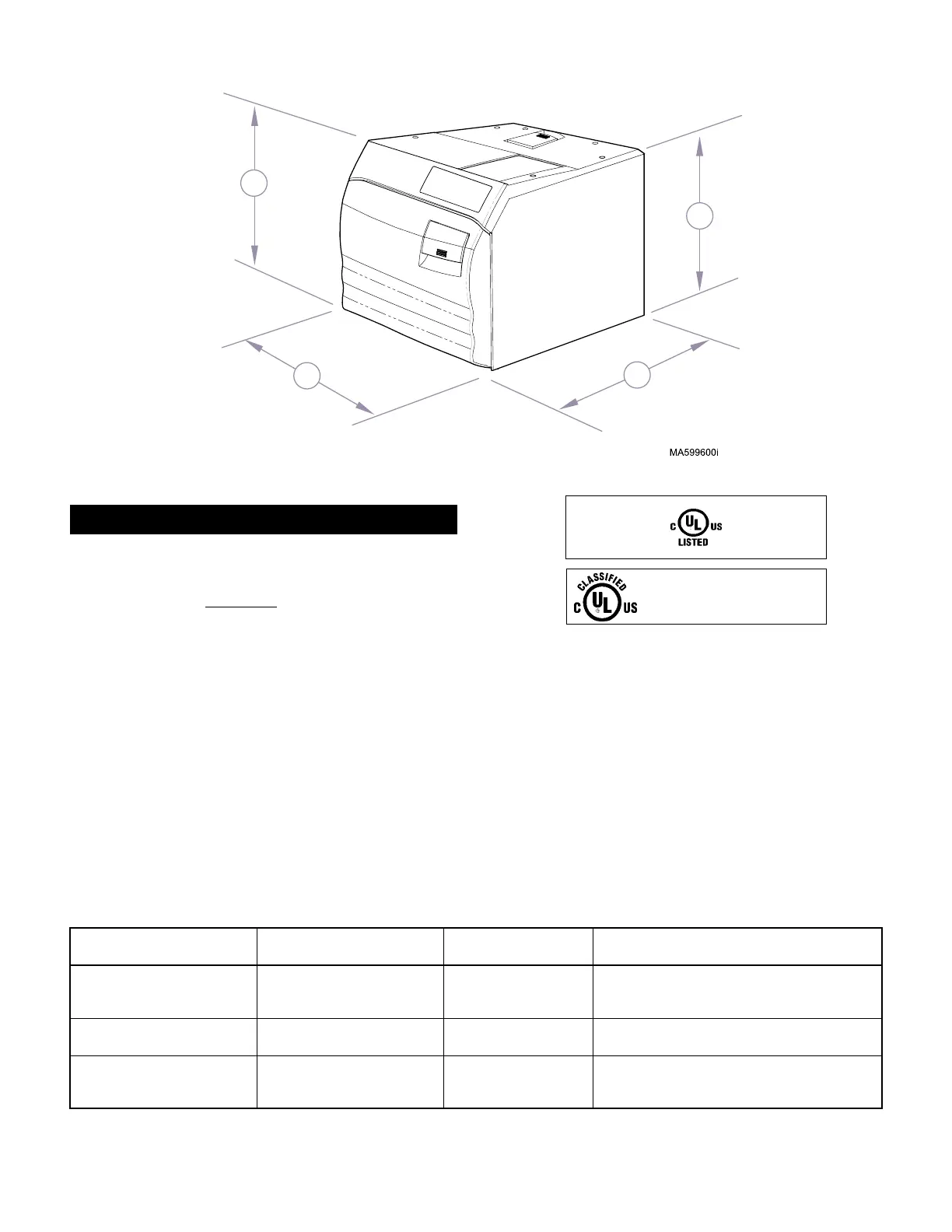

B

A

C

D

Figure 1-4.

M9 & M11 Sterilizers

UL61010A-1

LABORATORY

EQUIPMENT

59FM

Medical Equipment

UL61010A-1; UL61010A-2-041

59M Midmark Corporation

Table 1-3. Special Tool List

Description of Special Tool Manufacturer

Manufacturer’s Part

Number

Purpose of Special Tool

Digital Multimeter w/ Amp

Clamp

(capable of displaying 3 digits)

Commercially Available Any Type For performing continuity, voltage, and current

checks.

Digital Thermometer Commercially Available Any Type Used to check temperatures in order to diagnose

malfunctions.

Pressure Gauge Test Harness Midmark Corporation

1-800 643-6275

Technical Service Dept.

002-0372-00 Used to check pressure in chamber during a cycle

in order to diagnose malfunctions.

Return To Table of Contents

Loading...

Loading...