SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-21 Printed in U.S.A.

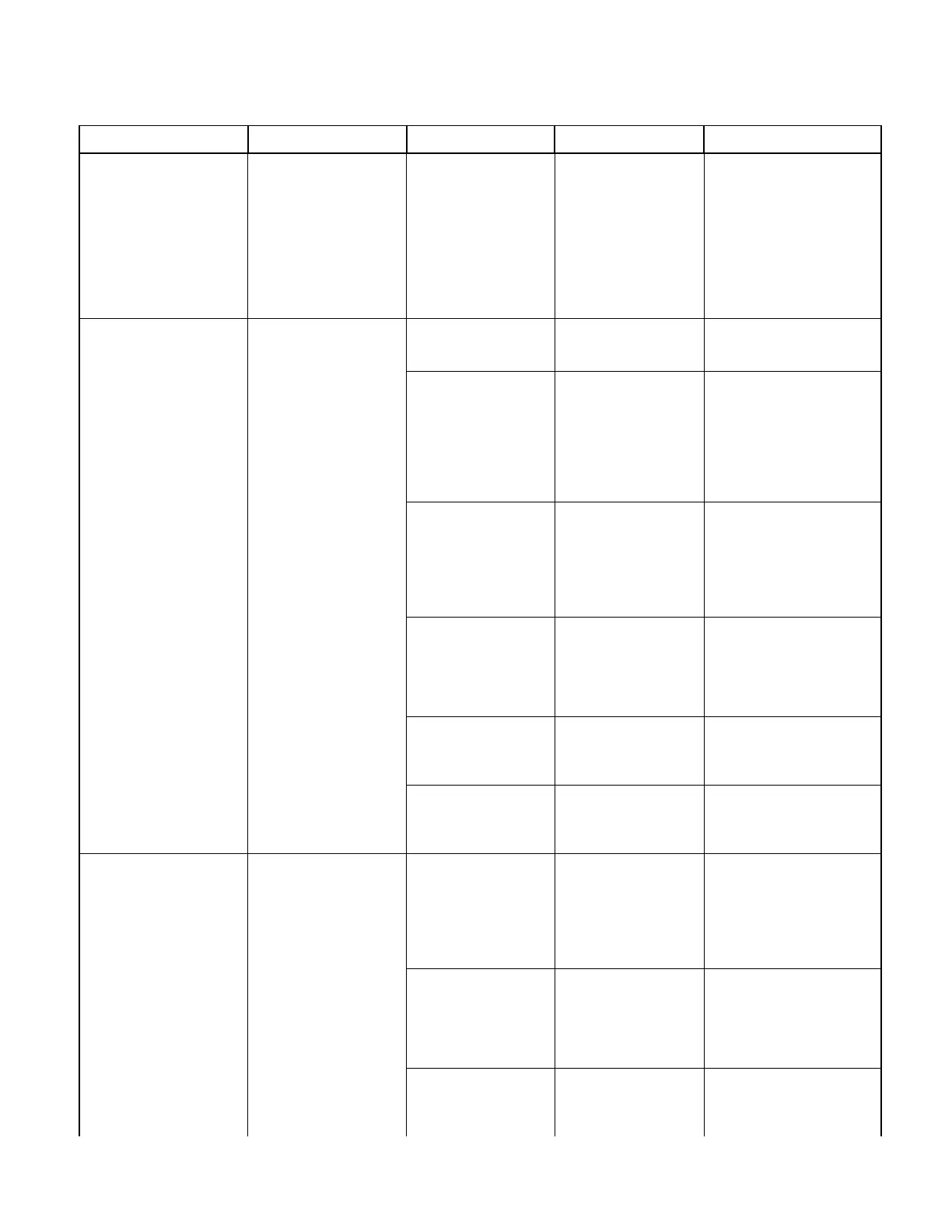

Code C677. (Continued)

(Error Type: FATAL )

(Continued)

C677: DRY MODE

PRESSURE OVERLIM

UNPLUG / RE-PLUG UNIT

Gauge pressure inside

chamber is greater than

34.8 PSIG (240 kPa) dur-

ing DRY mode.

Pressure Transducer or

Main P.C. Board Mal-

functioning.

Check for 5.0 VDC

between TP2 & TP4 &

pins of Pressure Trans-

ducer. (Refer to Sche-

matic in Section 5).

Voltage should be apprx.

4.5 VDC at all times with

unit plugged in. Also, run

Service Diagnostics.

If voltage is not present or Ser-

vice Diagnostics reveals a

problem replace P.C. Board

(Refer to para 4.13).

Code

C980.

(Error Type: FATAL )

Note: When a Code ends in

“0” it means unit had a sup-

ply power interruption.

The operator could have

unplug the unit when a previ-

ous Code was displayed.

Always go to Service Diag-

nostics and check previous 5

codes that are displayed.

C980: POWER UP MODE

HI-LIMIT OPEN

UNPLUG / RE-PLUG UNIT

High Limit Switch has

opened for at least 1/4 sec-

ond during POWER UP

mode.

May be due to a malfunc-

tion that occurred previ-

ously to displayed code.

Go to Service Diagnos-

tics and check previous 5

displayed codes.

Refer to Code Numbers in

Troubleshooting Guide to

determine correction.

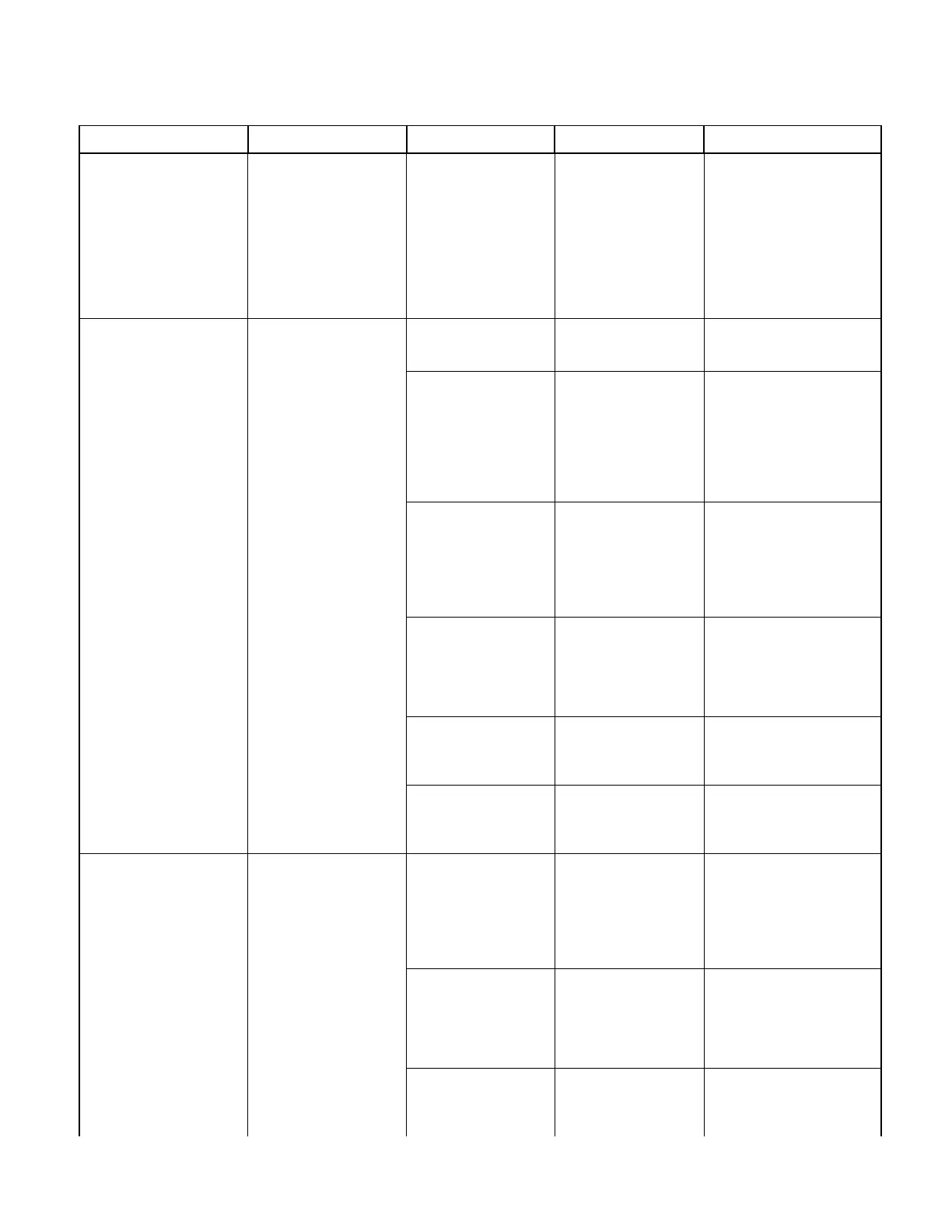

Water level of reservoir is

covering outlet of con-

densing coil.

Water siphons back into

chamber resulting in low

temperature.

Check if condensing coil

outlet is beneath water

level in reservoir.

Inform operator not to over fill

reservoir.

If reservoir is not over filled but

coil outlet is submerged, bend

coil so outlet is a maximum of

1 7/8” below top of lid opening.

Do not allow coil to touch top

or sides of reservoir.

High Limit Switch(s) is

weak and opens prema-

turely.

Disconnect power and

check continuity across

high limit switches.

Limits opens at 425°F

(218°C) to 475°F (246°C)

Close at 325°F (163°C)

to 375° F (191° C)

If continuity is not present and

temperature at limit is below

the Limit’s “Open” temperature

replace Limit Switch (Refer to

para 4.19).

High Limit Switch(es)

opened normally due to

temperature surpassing

425°F (218°C) to 475°F

(246°C)

Disconnect power and

allow unit to cool. Run

Service Diagnostics and

check individual compo-

nents to assure they are

functioning correctly.

If a component malfunc-

tioned, producing the overheat

condition, repair or replace the

specific component.

Wires or connectors at

High Limit Switch(es)

loose, disconnected or

broken.

Check conditions of all

connectors and related

wires.

Repair or replace connectors

or wires. Refer to Section 5 for

Schematics.

P.C. Board malfunction-

ing.

Run Service Diagnostics

and make various volt-

age checks as indicated

on P.C. Schematic.

Replace P.C. Board (Refer to

para 4.13).

Code

C981 SELECT

Code C982 FILL

Code C983 HEATUP

Code C984 STERILIZE

Code C985 VENT

(Error Type: FATAL )

(Refer to column on left for

codes and description)

C98X: XXXXXX MODE

HI-LIMIT OPEN

UNPLUG / RE-PLUG UNIT

High Limit switch(es) has

opened for at least 1/4 sec-

ond during specific mode.

High Limit Switch(es) is

weak and opens prema-

turely.

Disconnect power and

check continuity across

high limit switch.

Limits opens at 425°F

(218°C) to 475°F (246°C)

Close at 325°F (163°C)

to 375° F (191° C)

If continuity is not present and

temperature at limit is below

the Limit’s “Open” temperature

replace Limit Switch (Refer to

para 4.19).

High Limit Switch(es)

opened normally due to

temperature surpassing

425°F (218°C) to 475°F

(246°C)

Disconnect power and

allow unit to cool. Run

Service Diagnostics and

check individual compo-

nents to assure they are

functioning correctly.

If a component malfunc-

tioned, producing the overheat

condition, repair or replace the

specific component.

Wires or connectors at

High Limit Switch(es)

loose, disconnected or

broken.

Check conditions of all

connectors and related

wires.

Repair or replace connectors

or wires. Refer to Section 5 for

Schematics.

Table 2-3. Troubleshooting Guide

Problem Display / Symptom Probable Cause Check Correction

Return To Table of Contents

Loading...

Loading...