SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-20 Printed in U.S.A.

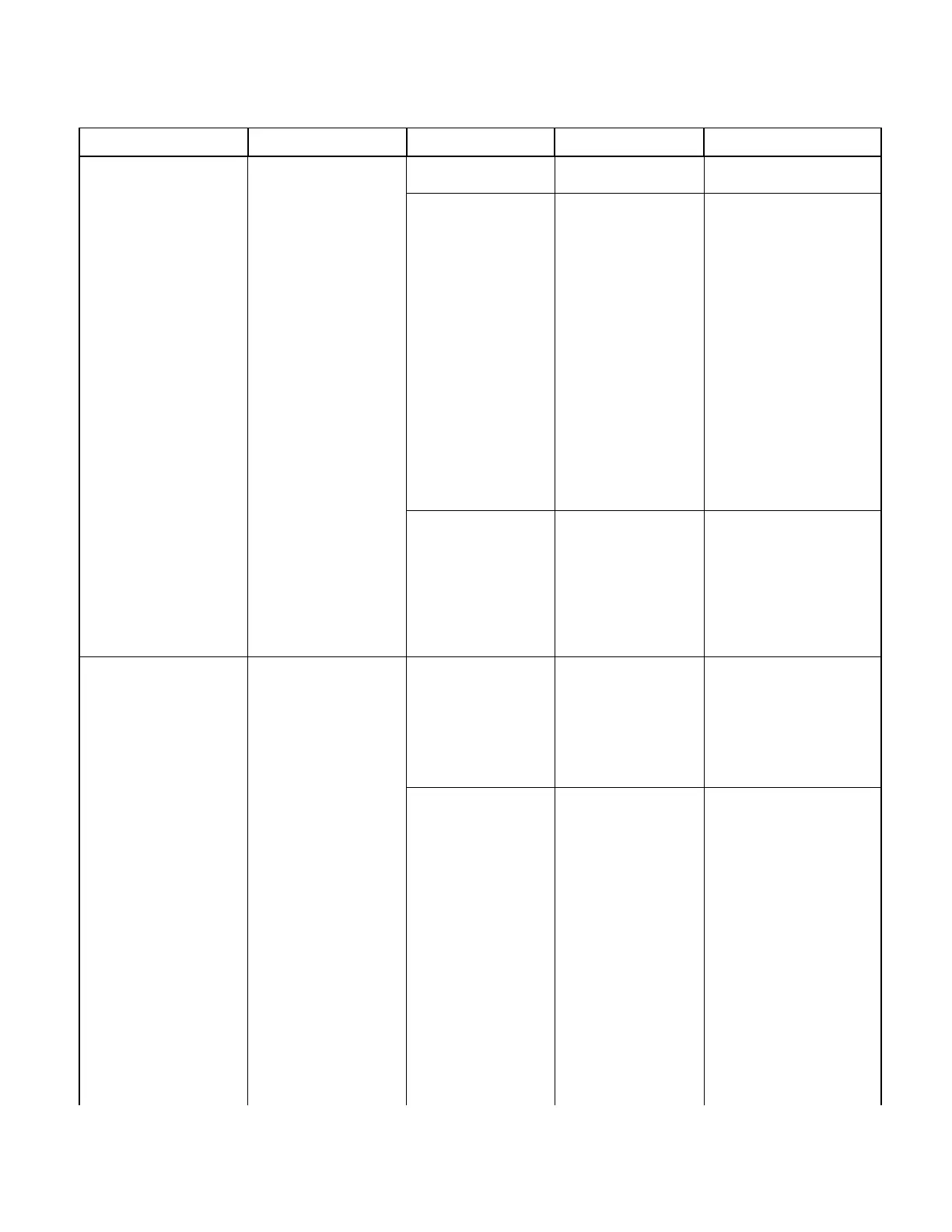

Code C675 VENT

(Error Type: FATAL )

(Refer to column on left for

codes and description)

C67X: XXXXXX MODE

PRESSURE OVERLIM

ITEMS NOT STERILE

UNPLUG / RE-PLUG UNIT

Gauge pressure inside

chamber is greater than

34.8 PSIG (240 kPa) dur-

ing specific mode.

Filter screen in chamber

restricted.

Remove filter screen and

check condition.

Clean or replace filter screen.

Vent Valve malfunction-

ing or related lines or fit-

tings restricted.

•Run Service Diagnostics

and check Vent Valve

Operation. Check for

debris in lines and valve.

•If Vent Valve does not

operate check for line

voltage at terminals of

valve.

•If line voltage is present

but valve does not oper-

ate, disconnect power

from unit.

Disconnect leads from

Vent Valve coil and check

continuity.

115 VAC = 0.4 MOhms

230 VAC = 3.2 MOhms

(cold readings +/- 10 %)

If no continuity replace

valve.

Clean or replace Vent Valve,

related lines and fittings (Refer

to para 4.18).

Pressure Transducer or

Main P.C. Board Mal-

functioning.

Check for 5.0 VDC

between TP2 & TP4 &

pins of Pressure Trans-

ducer. (Refer to Sche-

matic in Section 5).

Voltage should be apprx.

4.5 VDC at all times with

unit plugged in. Also, run

Service Diagnostics.

If voltage is not present or Ser-

vice Diagnostics reveals a

problem replace P.C. Board

(Refer to para 4.13).

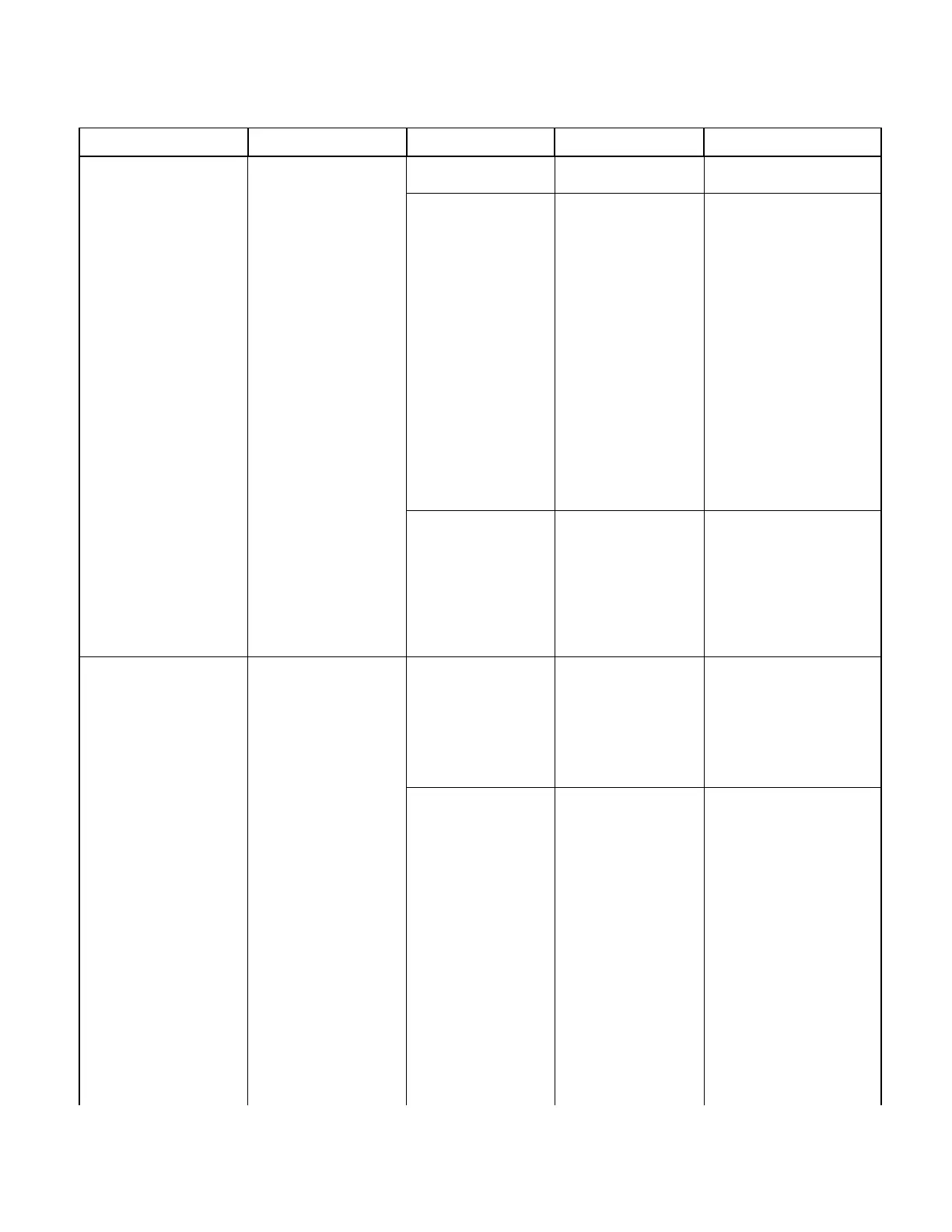

Code

C677.

(Error Type: FATAL )

C677: DRY MODE

PRESSURE OVERLIM

UNPLUG / RE-PLUG UNIT

Gauge pressure inside

chamber is greater than

34.8 PSIG (240 kPa) dur-

ing DRY mode.

Door did not fully open

even though latch

released allowing cham-

ber to retain a slight

pressure.

Run Service Diagnostics

to check component

operation. Check number

of cycles (back-to-back)

Operator ran before

problem occurred. Check

condition of door gasket.

If door gasket is worn or dirty

clean or replace gasket (Refer

to para 4.XX).

Inform Operator that problem

could occur when back-to-

back cycles have been run

and Start-up temperature is

230° F [110° C] or above.

Vent Valve malfunction-

ing or related lines or fit-

tings restricted.

•Run Service Diagnostics

and check Vent Valve

Operation. Check for

debris in lines and valve.

•If Vent Valve does not

operate check for line

voltage at terminals of

valve.

•If line voltage is present

but valve does not oper-

ate, disconnect power

from unit.

Disconnect leads from

Vent Valve coil and

check continuity.

115 VAC = 0.4 MOhms

230 VAC = 3.2 MOhms

(cold readings +/- 10 %)

If no continuity replace

valve.

Clean or replace Vent Valve,

related lines and fittings (Refer

to para 4.18).

Table 2-3. Troubleshooting Guide

Problem Display / Symptom Probable Cause Check Correction

Return To Table of Contents

Loading...

Loading...