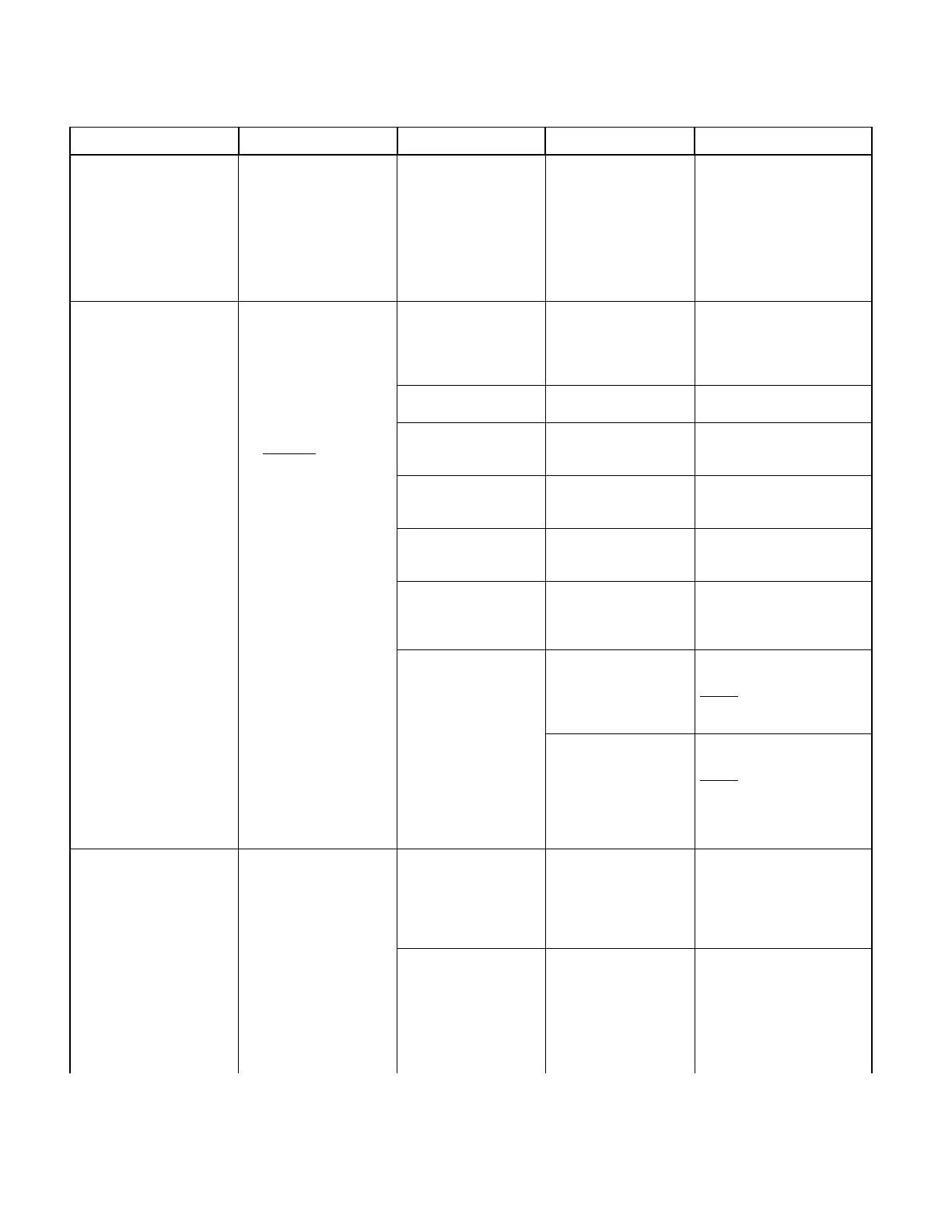

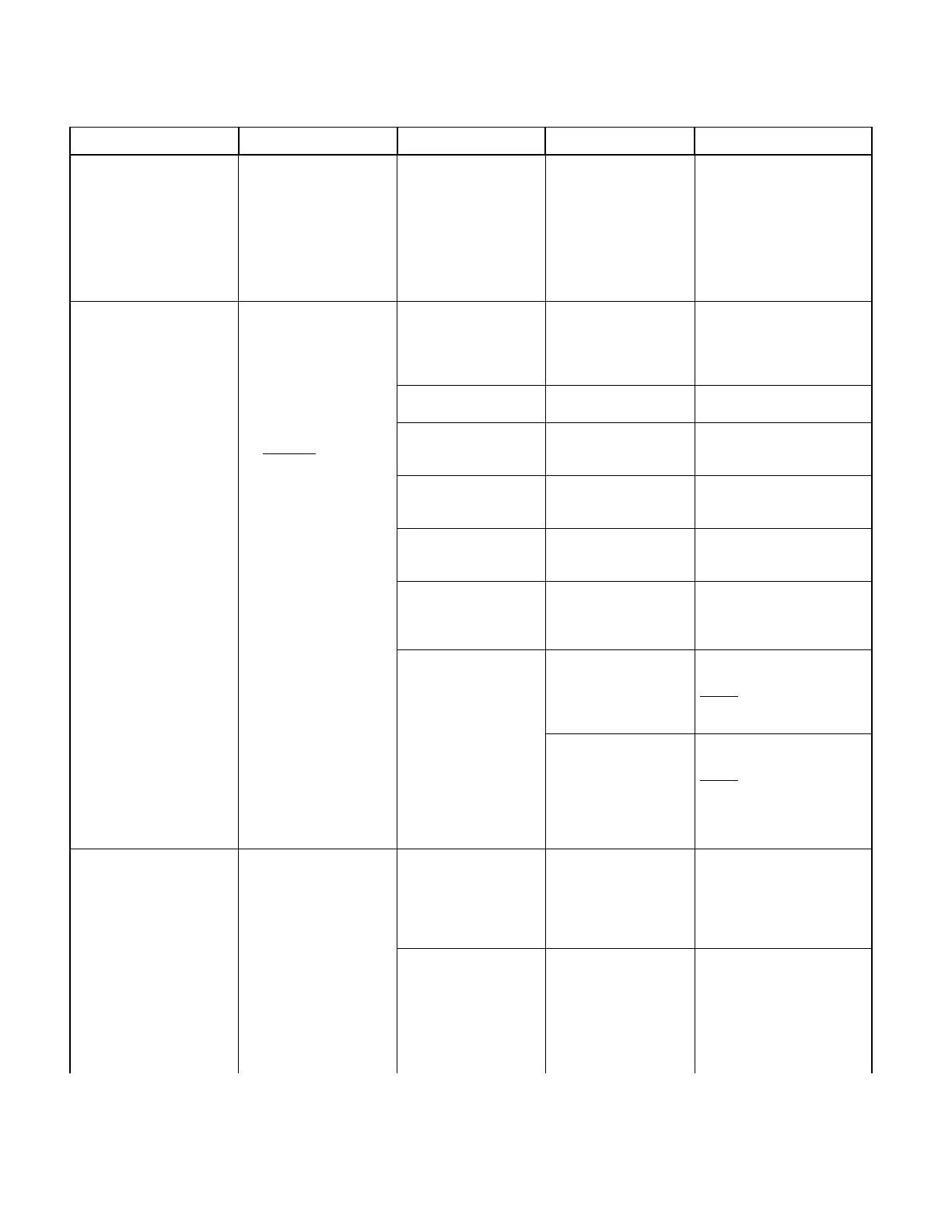

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-9 Printed in U.S.A.

Code C102 FILL

Code

C103 HEATUP

Code

C104 STERILIZE

Code

C105 VENT

Code

C106 DOOR OPEN

(Error Type: RESTART)

(Refer to column on left for

codes and description)

C10X: XXXXXX MODE

STOP PRESSED

ITEMS NOT STERILE

PUSH STOP TO RESTART

Operator pressed STOP

button, terminating that

specific Mode.

Check with person oper-

ating unit.

Explain proper operation.

Note: It may be necessary to

wait briefly (up to 1 minute)

while chamber pressure / tem-

perature dissipates.

Press STOP button to return

to SELECT CYCLE to initiate

a new cycle.

Code

C232.

(Error Type: RESTART)

C232: FILL MODE

WATER LOW

ITEMS NOT STERILE

PUSH STOP TO RESTART

After door is closed or

chamber vented, water fill

(level) sensor did not

detect water level within

the 5 minutes

required time

period.

Reservoir water level

low.

Check water level in Res-

ervoir.

Add water to reservoir so that

it is in the correct range on the

water level label.

Push STOP to restart back to

SELECT CYCLE Mode.

Mesh filter restricted. Check if mesh filter is

clogged.

Clean or replace mesh filter.

Water Fill (level) Sensor

dirty.

Check Water Fill (level)

Sensor for dirt or corro-

sion.

Clean or replace Water Fill

(level) Sensor (Refer to

para 4.21).

Fill Valve or related

plumbing clogged.

Check Water Fill Valve

and related tubing for

restrictions.

Clean or replace Water Fill

Valve (Refer to para 4.18).

Fill Valve coil malfunc-

tioning.

Check continuity of

Water Fill Valve solenoid

coil for open winding.

Replace Water Fill Valve

(Refer to para 4.18).

Plug connection(s) W3 /

W4 loose or discon-

nected or broken wires.

Check Water Fill Valve

connections at W3 / W4

on P.C. Board and

related leads.

Assure W3 / W4 plug connec-

tions are securely connected

and related leads are not bro-

ken.

P.C. board malfunction-

ing

Check for line (115 or

230 VAC) voltage at W3 /

W4.

If no voltage replace P.C.

Board (Refer to para 4.13).

Always

run Service Diagnos-

tics (Para 2.2) before replac-

ing P.C. Board.

Check for 4.5 to 5.0 VDC

at J8 pins 1 & 2 on P.C.

Board.

Run a Service Diagnos-

tics to check functions of

Fill Valve and related

components

If no voltage replace P.C.

Board (Refer to para 4.13).

Always

run Service Diagnos-

tics (Para 2.2) before replac-

ing P.C. Board.

Code

C326.

(Error Type: AUTOMATIC)

C326: DOOR MODE

DOOR CLOSED

OPEN DOOR

Door remains closed one

second after door opening

motor output was turned

from On to Off in an

attempt to open door.

Door may be hanging up

on door opening motor

latch.

Check position of door

(open or closed).

Run Service Diagnostics

and run Door Opening

Tes t .

Run another cycle. If condition

persist where door must be

manually opened check door

opening assembly for adjust-

ment or replace assembly

(Refer to para 4.12).

Door Switch malfunction-

ing.

Check Door Switch con-

tacts to assure they close

when door is closed and

open when door is

opened.

If contact of Door Switch

shows open when door is

closed replace switch (Refer

to para 4.11).

Table 2-3. Troubleshooting Guide

Problem Display / Symptom Probable Cause Check Correction

Return To Table of Contents

Loading...

Loading...