SECTION IV

MAINTENANCE / SERVICE

© Midmark Corporation 2002 SF-1803 Page 4-9 Printed in U.S.A.

(7) If excessive force is required to open pressure

relief valve or pressure relief valve will not

reseat properly, the pressure relief valve must

be replaced (Refer to para. 4.17).

4.17 Pressure Relief Valve

A. Removal

(1) Unplug power cord from outlet receptacle.

(2) Remove all panels and top cover (Refer to

para 4.2).

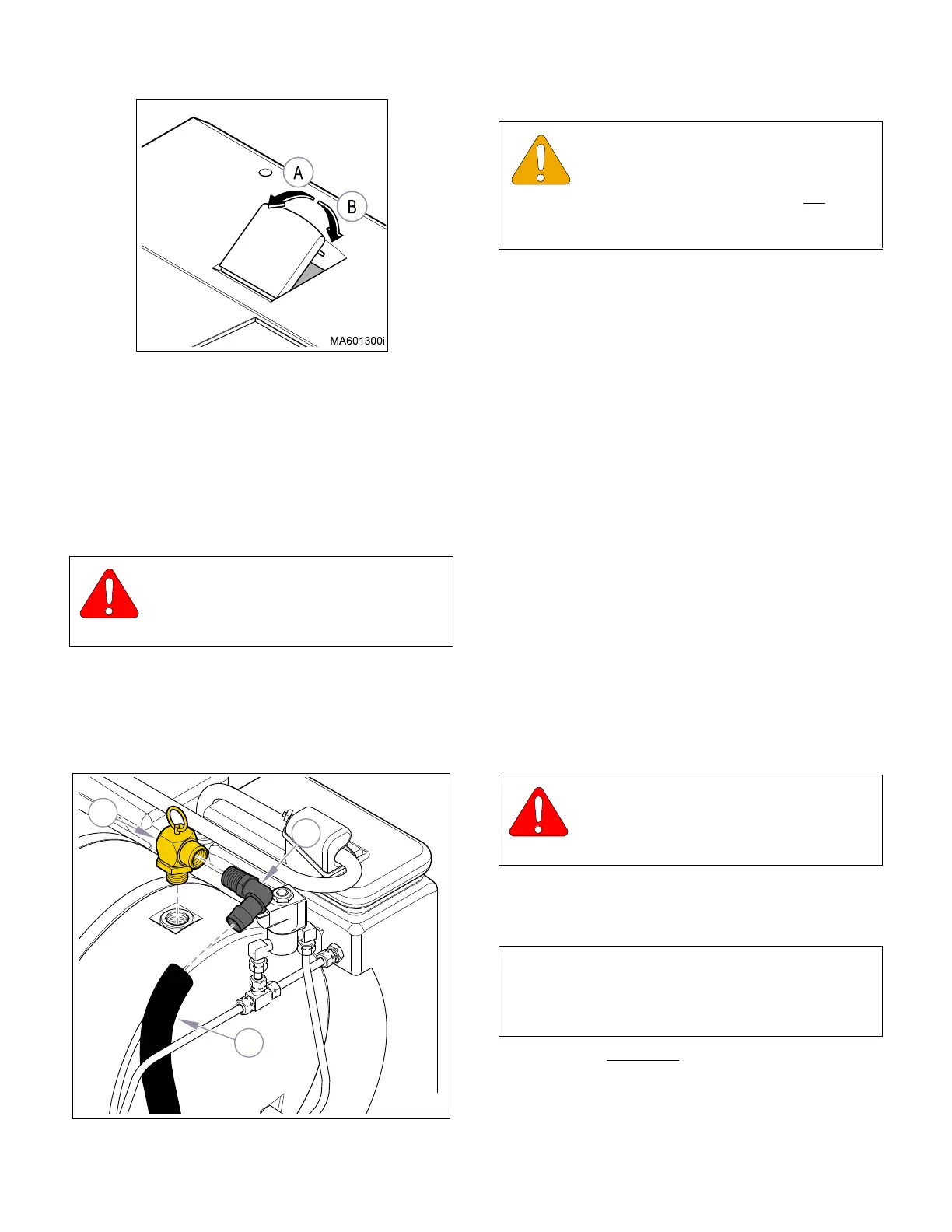

(3) Remove tubing (1, Figure 4-17) and elbow (2)

from pressure relief valve (3).

(4) Remove pressure relief valve (3).

B. Installation

(1) Coat threads of pressure relief valve

(3, Figure 4-26) with high temperature

pipe thread compound (Loctite 565).

(2) Install pressure relief valve (3).

(3) Install elbow (2) on pressure relief valve (3).

(4) Install tubing (1) on elbow (2) and route tubing

through tubing hole in bottom, back of base.

(5) Install L.H. panel and Top Cover (Refer to

para. 4.2).

(6) Plug unit in, run a cycle to place pressure on

lines and fittings, then check for leaks and oper-

ation of pressure relief valve (3).

(7) Install Back and R.H. side panel (Refer to

para 4.2).

4.18 Vent or Fill Valve

A. Removal

(1) Unplug power cord from outlet receptacle.

(2) Remove R.H. side and back panel (Refer to

para 4.2).

(3) Drain water from reservoir (Refer to para 4.6).

(4) Disconnect electrical wires from terminals of

the Vent (1, Figure 4-18) or Fill (2) solenoid

valve.

(5) If removing Vent Valve (1) , disconnect com-

pression fitting (3) and line on top of valve.

B. Disassembly

(1) On the Vent Valve

, remove the reducer

(1, Figure 4-19) and male connector (2) fittings.

(2) Remove nut (3), solenoid cover (4), and sole-

noid coil (5).

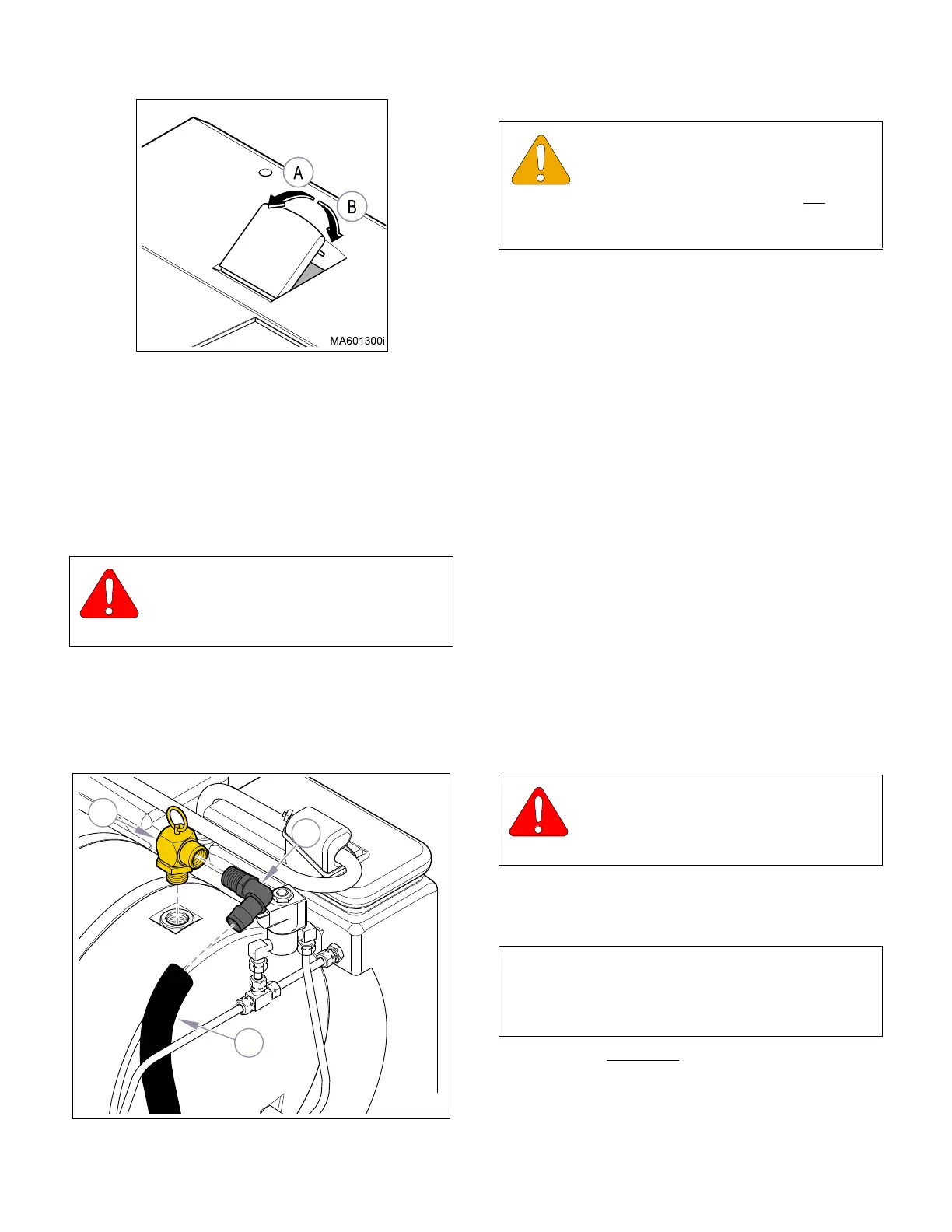

WARNING

Pull upward on the pressure relief handle

to purge any pressure inside chamber

(Refer to para 4.16).

Figure 4-16. Pressure Relief

Figure 4-17. Pressure Relief Valve

MA617600i

1

3

2

EQUIPMENT ALERT

Use a pipe thread compound on the steril-

izer fittings capable of withstanding the

operating pressures and temperatures. Do not

use a

teflon tape as particles may migrate through system

and cause blockage.

WARNING

Pull up on Pressure Relief Valve handle

to purge any pressure inside chamber

and lines before working on system.

NOTE

The steps for disassembly and assembly of the Vent

or Fill Valves are almost identical unless called out for

the specific valve.

Return To Table of Contents

Loading...

Loading...