SECTION III

SCHEDULED MAINTENANCE

© Midmark Corporation 2002 SF-1803 Page 3-1 Printed in U.S.A.

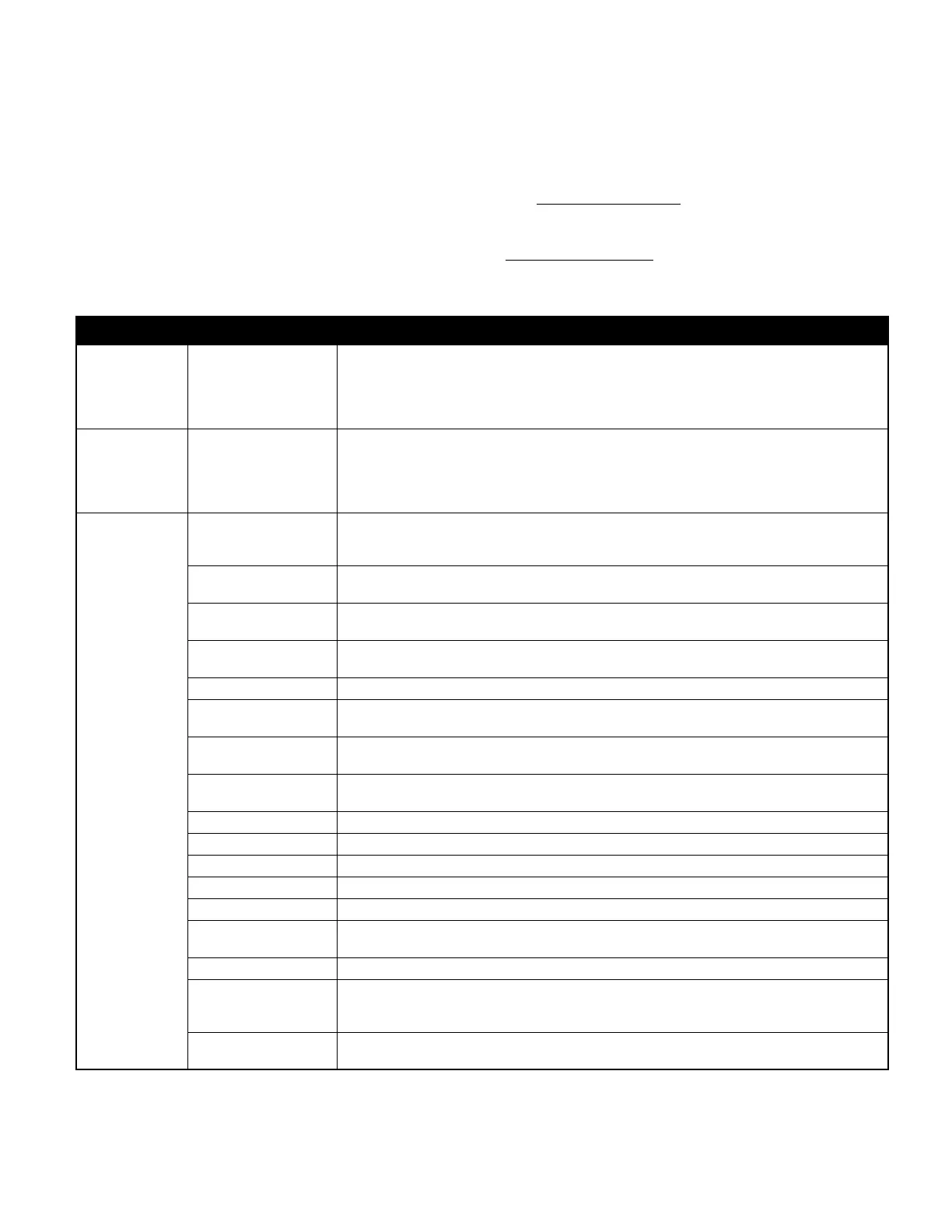

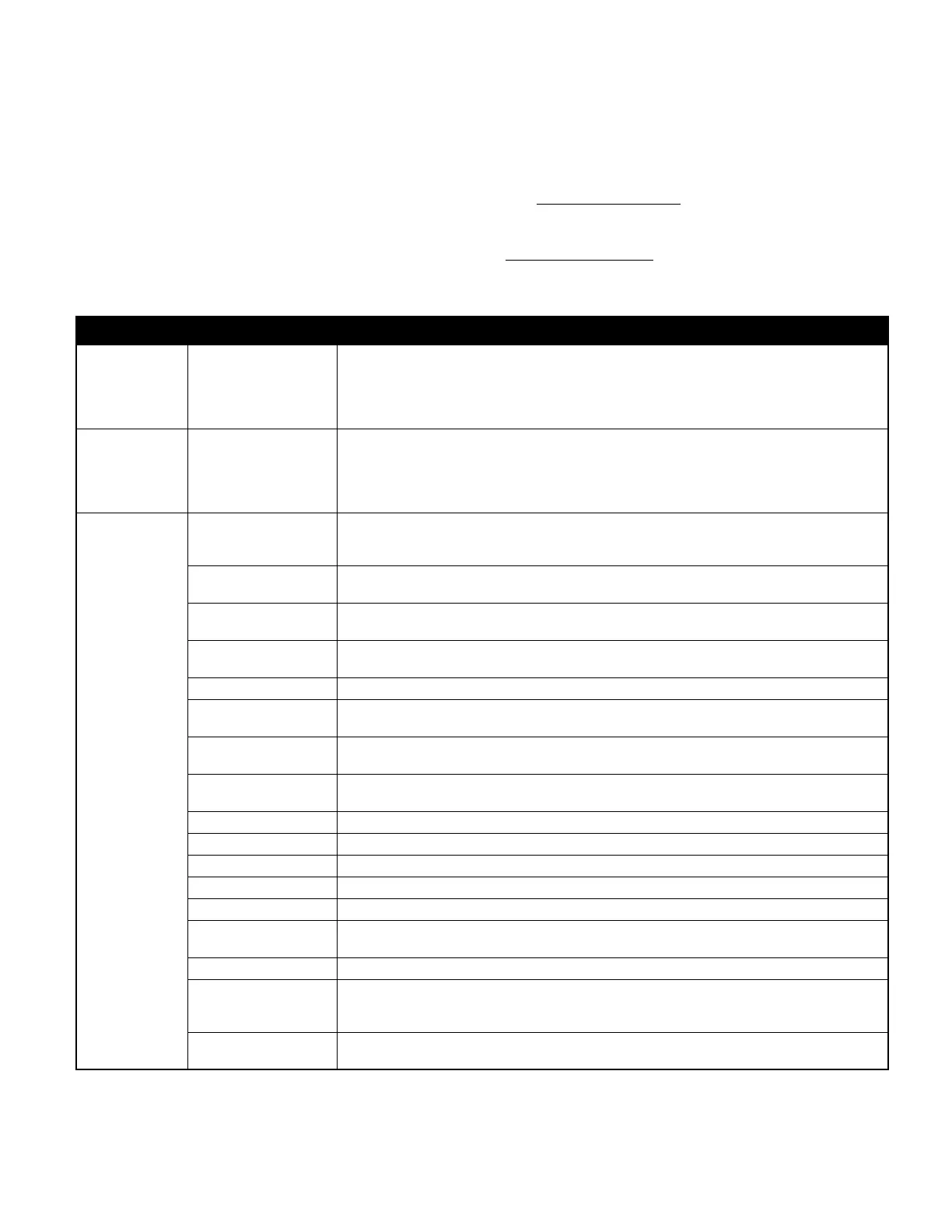

3.1 Scheduled Maintenance

Table 3-1 is a Scheduled Maintenance Chart which lists

the inspections and services that should be performed

periodically on the Model M9 or M11 Sterilizers. These

inspections and services should be performed as often

as indicated in the chart.

Also, periodically the display on the Sterilizer will inform

the operator that either a Weekly or Monthly Mainte-

nance is required.

The Weekly Maintenance

display occurs when the Ster-

ilizer software senses that 7, 14, and 21 days have

passed.

Monthly Maintenance

is displayed when 28 days have

passed.

Interval Inspection or Service What to Do

Weekly

(Maintenance

should be per-

formed by Opera-

tor).

Clean Chamber and

Trays.

Drain water from the Sterilizer using drain tube in front of unit. Allow unit to cool to prevent burns.

Wash inside of chamber and trays with a solution of mild soap or Speed-Clean® and distilled

water. Remove any debris in or around the mesh filters in the chamber and rinse the filter.

Wipe off the door gasket and mating surfaces using a damp cloth and inspect gasket for damage.

Replace gasket if necessary. Refer to Installation / Operation Manual.

Monthly

(Maintenance

should be per-

formed by Opera-

tor).

Clean and flush the

chamber and related

plumbing. Wipe off trays.

Using Speedclean®, clean the chamber and related plumbing. Refer to the Installation / Operation

Manual, Operator Maintenance for Monthly cleaning procedures.

Semi-annually Obvious damage Visually check condition of sterilizer for obvious damage such as: cracks in components, missing

components, dents in components, or any other visible damage which would cause sterilizer to be

unsafe to operate or would compromise its performance. Repair sterilizer as necessary.

Fasteners / hardware Check for missing or loose fasteners / hardware. Replace any missing hardware and tighten any

loose hardware as necessary.

Warning and instructional

decals

Check for missing or illegible decals. Replace decals as necessary.

Pivot points / moving

parts.

Lubricate all exposed pivot points, and moving parts with high temperature, non-toxic, silicone

based lubricant.

Display Overlay Check for missing, damaged, or illegible display overlay. Replace display overlay if necessary.

Wiring Connections Check condition of all wiring connections. Clean, tighten or replace any dirty, loose, or damaged

connections.

Free movement of door

latch.

Clean door latch with solvent. Lubricate door latch and door pins with high temperature, non-toxic,

silicone grease.

Door interlock switch

operation.

Check to assure door switch operates correctly. Run Service Diagnostics.

Door gasket Check gasket for deterioration. Clean and, if necessary, replace gasket (Refer to para 4.8).

Chamber mesh filter. Inspect, clean or replace filters if necessary (Refer to para 4.7).

Water Level Sensor Clean or replace water level sensor (Refer to para 4.21).

Tubing Inspect all tubing for cleanliness. Clean or replace if required.

Reservoir Inspect reservoir for cleanliness and clean or replace if required (Refer to para 4.22).

Pressure Relief Valve Perform a pressure relief valve check (Refer to para 4.16). Replace pressure relief valve if required

(Refer to para 4.17)

Printer (optional) Check printer operation. Replace ribbon cartridge if required.

Operational Test Run a Normal Operation to determine if the sterilizer is operating within its specifications (Refer to

para 2.1). If it is determined there is a problem run Service Diagnostic (Refer to para. 2.2) and

review the Troubleshooting Guide (Refer to para 2.3) before replacing any components.

Service Diagnostics Test Run the Service Diagnostics (Refer to para. 2.2) to check the Main P.C. Board and various compo-

nents.

SECTION III

SCHEDULED MAINTENANCE

Return To Table of Contents

Loading...

Loading...