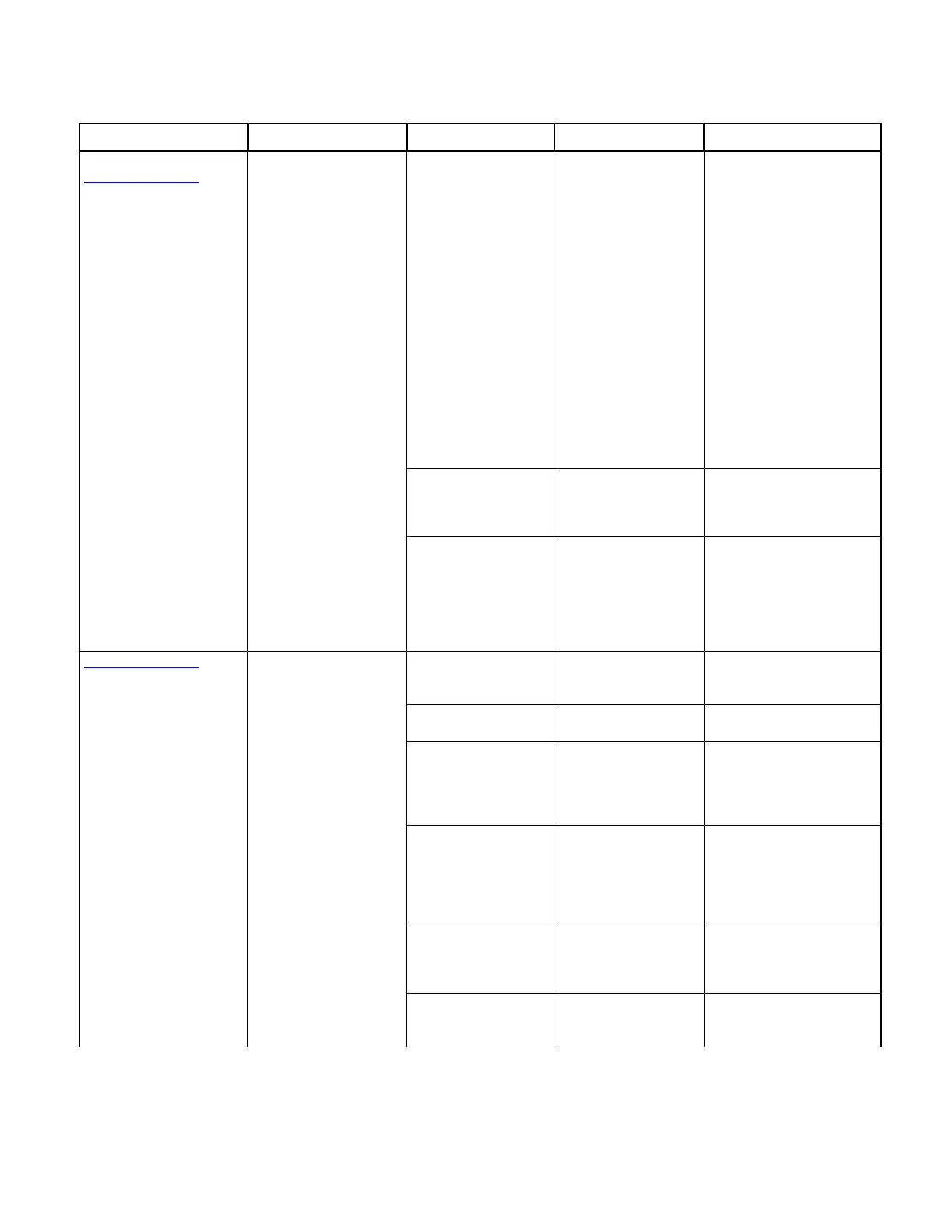

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-23 Printed in U.S.A.

(Continued)

(Non-Coded Errors)

Sterilizer not drying instru-

ments properly.

(Continued)

Instruments are wet after

drying cycle is complete.

Vent Valve malfunction-

ing or related lines or fit-

tings restricted.

•Run Service Diagnostics

and check Vent Valve

Operation. Check for

debris in lines and valve.

•If Vent Valve does not

operate check for line

voltage at terminals of

valve.

•If line voltage is present

but valve does not oper-

ate, disconnect power

from unit.

Disconnect leads from

Vent Valve coil and

check continuity.

115 VAC = 0.4 MOhms

230 VAC = 3.2 MOhms

(cold readings +/- 10 %)

If no continuity replace

valve.

Clean or replace Vent Valve,

related lines and fittings (Refer

to para 4.18).

Heater not functioning. Run Service Diagnostics

and check operation

heater, and various com-

ponents.

Replace malfunctioning heater

or related component(s).

High Limit Switch(es) is

stuck in an “open” posi-

tion.

Disconnect power and

check continuity across

High Limit Switch.

Limits opens at 425°F

(218°C) to 475°F (246°C)

Close at 325°F (163°C)

to 375° F (191° C)

If continuity is not present and

temperature at limit is below

the Limits “Open” temperature

replace Limit Switch (Refer to

para 4.19).

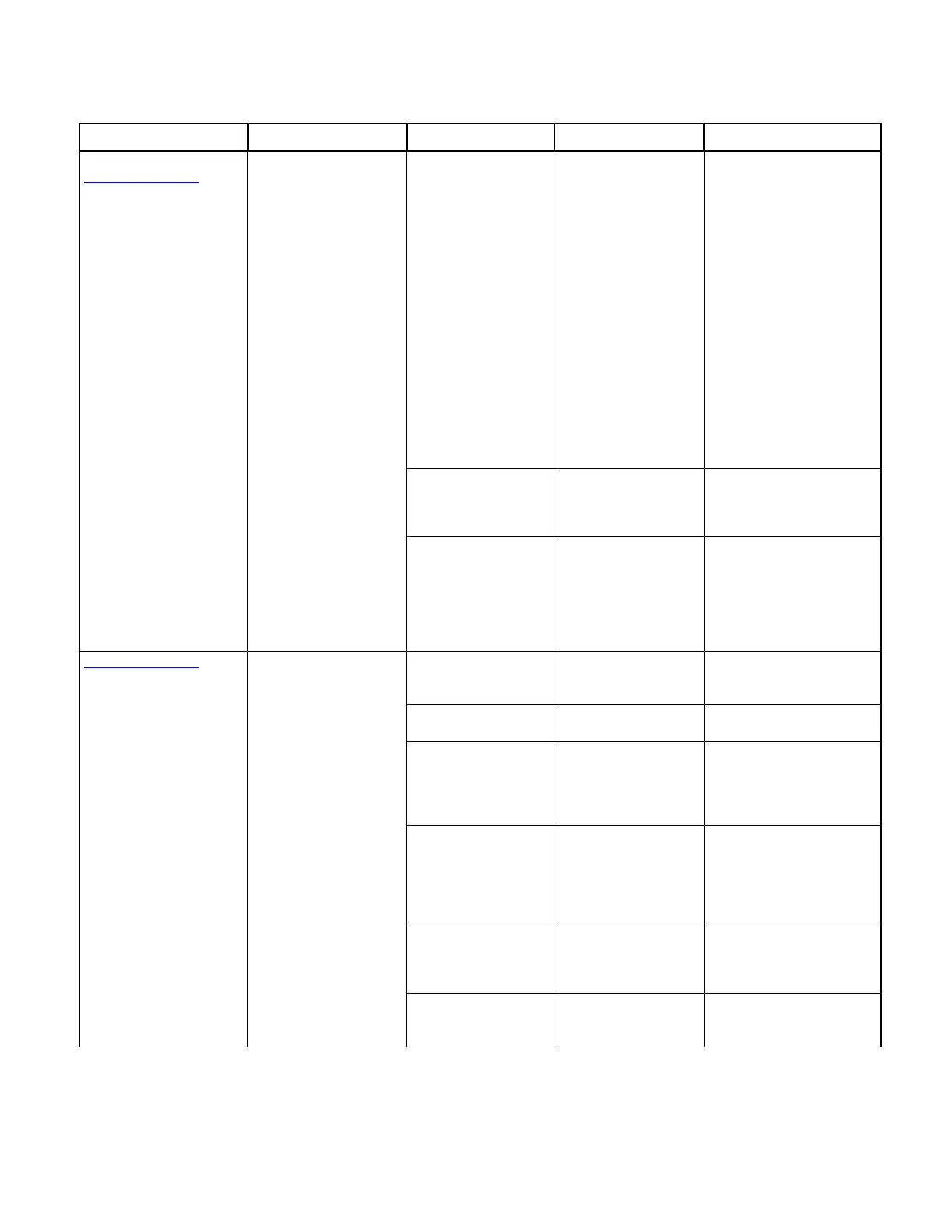

(Non-Coded Errors)

Biological indicator strip

designates unit not steril-

izing.

Positive biological indica-

tor.

No color change, or incom-

plete change has occurred

on chemical indicator strip.

Sterilizer overloaded Check that pressure ves-

sel is not overloaded with

heavy linen packs.

Remove packs, allow unit to

cool and run a cycle. Instruct

operator to reduce load size.

Improper operation. Procedures used by

operator(s).

Demonstrate Normal Opera-

tion to operator(s).

Using trays for instru-

ments not manufacture-

red for sterilizer. Does

not get proper air flow or

steam penetration.

Check style of instrument

trays being used.

Explain to operator(s) to use

only trays manufactured for

use in M9 / M11 Sterilizer.

Wrong type of biological

indicator being used for

this type sterilizer.

Check biological indica-

tor to assure it is for grav-

ity type sterilizers and

correct for the cycle

times and temperatures

being run.

Contact supplier of biological

indicator to acquire correct

indicators. Review Installation

/ Operation Manual for correct

procedures.

Chemical indicator strip

has come into contact

with water in the steril-

izer.

Check with operator on

positioning of indicator

strip in sterilizer.

Explain to operator correct

positioning to prevent direct

contact with water.

Indicator strips are being

stored in damp and / or

hot environment.

Check condition of area

where indicators are

stored.

Inform operator to follow stor-

age recommendation of indi-

cator manufacturer.

Table 2-3. Troubleshooting Guide

Problem Display / Symptom Probable Cause Check Correction

Return To Table of Contents

Loading...

Loading...