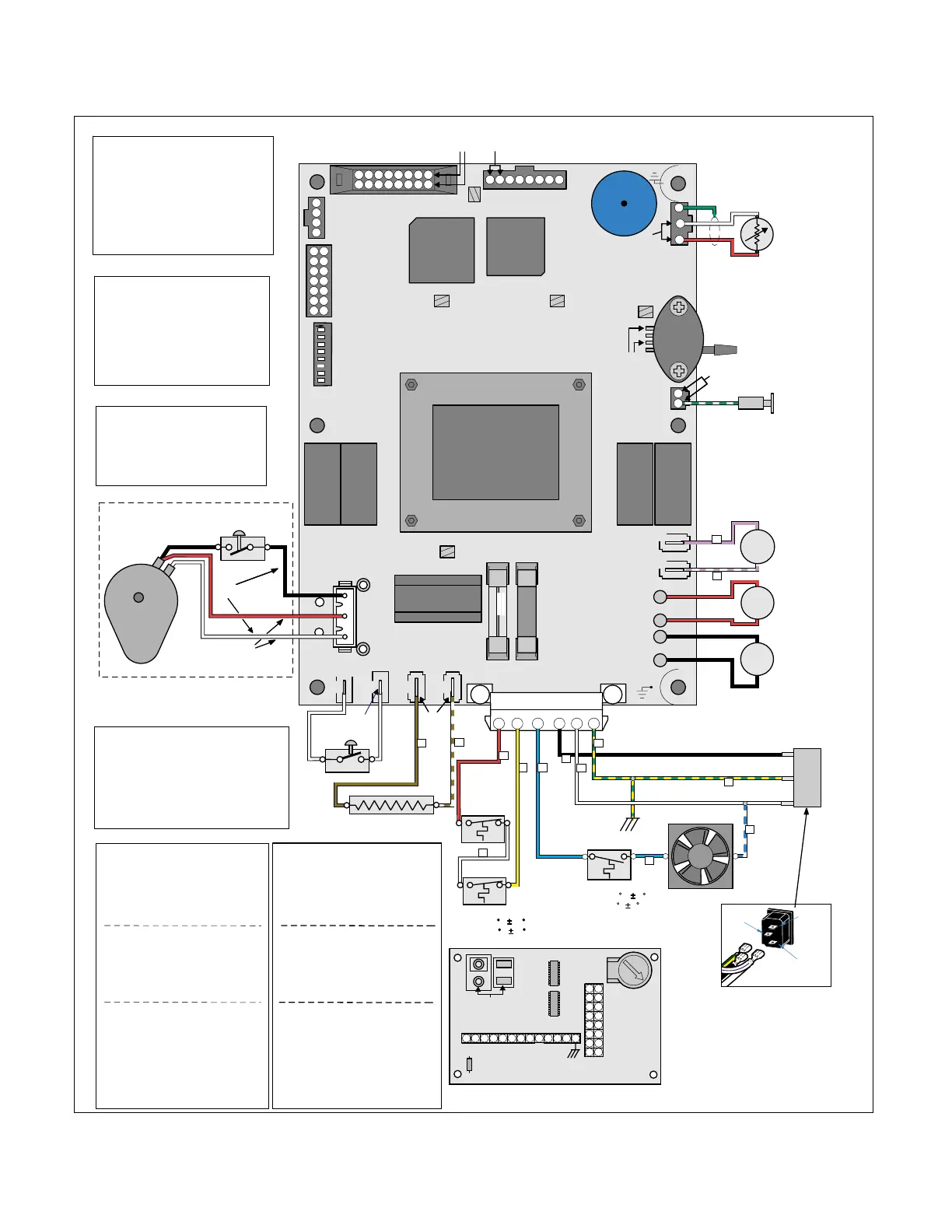

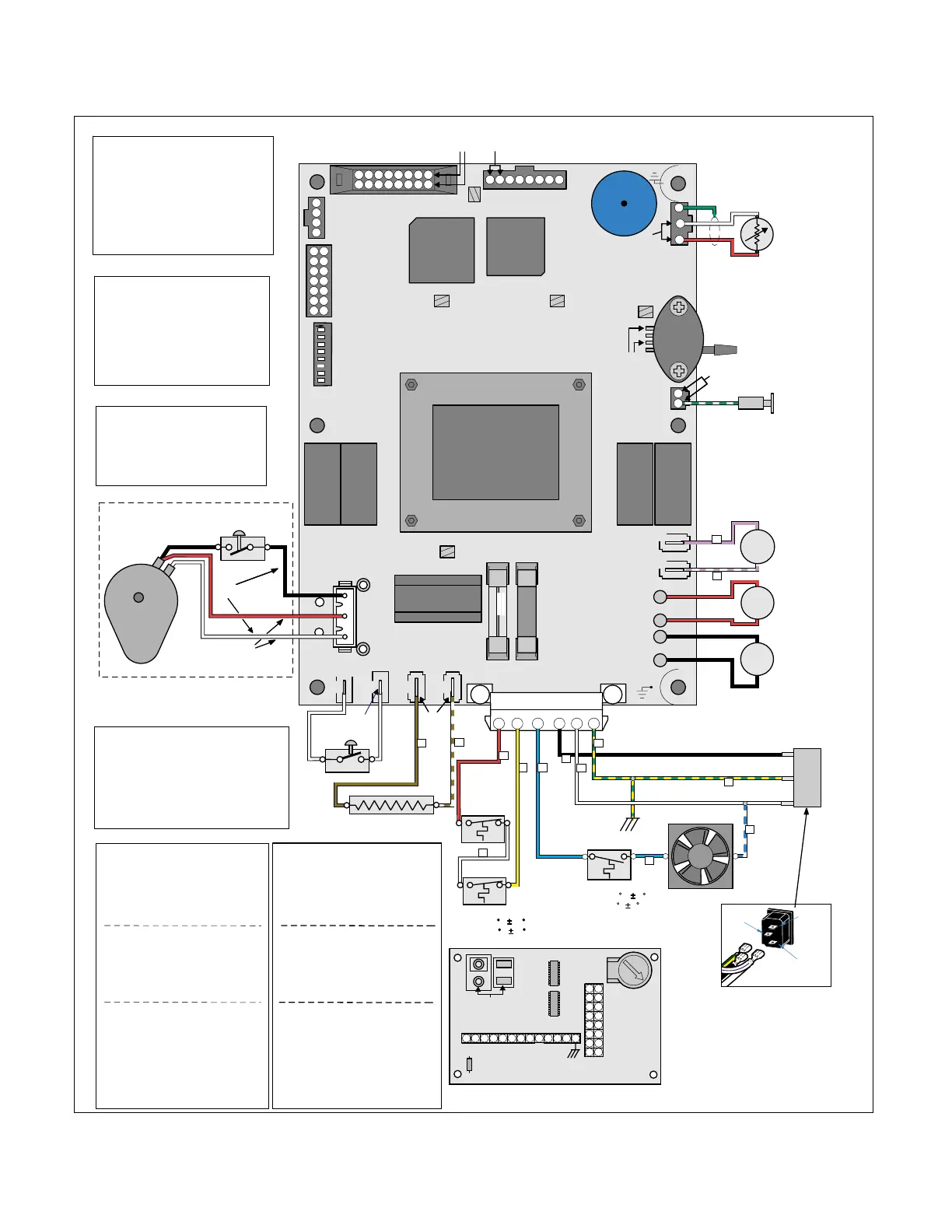

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-3 Printed in U.S.A.

White

Wht./Blue

Black

Grn/yl

Plug Outlet

MA612400

M9, M9D, M11, M11D

Sterilizer

Main P.C. Board

115 & 230 VAC

Single Phase 50 / 60 Hz

T1

Transformer

J1 J2 J3 J4

L1 N/L2

Heater

Door Interlock

Switch

W1

J5

F1

F2

W5

W6

W4

W3

J7

J6

Air

J8

Chamber

Level

U7

U8

SW1

(see Settings)

TP1

+12VDC*

TP2 Grd.

TP3

+5VDC*

TP4

+5VDC*

+5

VDC*

J12

Steam Temp

Sensor

DS1

TP5 Printer +5VDC*

J14 Printer

J13 Display

J10

RS232

PSD

JTAG

Port

J9

14

12

10

8

6

4

2

13

11

9

7

5

3

1

L1

High

Limit In

L1

VAC

Out

Fan

N / L2

L1

High

Limit

L1

(Line VAC)

Violet

Red

Blk

Wht

Grn/yl

Lt Blue

Grn

Fan Motor

Grn/yl

3

Lt

Blue

Lt

Blue

Blk

Yel

Fill

Vent

Fill

Solenoid

Coil (*)

Water

Level

Sensor

Probe

Wht/Blue

6

Wht

Vent (*)

Solenoid

Coil (NO)

Air

Solenoid

Coil (*)

Steam

Temperature

Sensor

Wht

Red

Red

Blk

Violet/Wht

Red

Blk

Wht / Grn

4

Brown

Brn/Wht

+5

VDC*

+4.5*

VDC

+4.5*

VDC

+5

VDC*

Line VAC

(When Door

is Open)

NO

C

Door

Interlock

Switch

Fan Thermostat (N/O)

Closes 130 F 8

Opens 101 F 6

C

NO

Pressure

Transducer

3

8

9

10

K4

Vent

Valve

K1

Heater

K5

Air

Valve

K2

Fill

Valve

4

5

6

11

12

7

1

4

3

2

1

135791113

15

2468101214

16

1234567

8

PS1

Line

VAC**

Wht

1

2

12

2

Wht

Grd.

Plug

Outlet

1

13

5

K3

Door

3

2

Red

Yel

Wht

Hi Limits (N/C)

Opens 450 F 25

Closes 350 F 25

14

J2

(To Switch Touch Pad)

D1

VR1

Display P.C. Board

R1

J3

(To J13 on Main

P.C. Board)

LCD Contrast

Adjustment

J1

16

3

1

5

7

9

11

13

15

2

4

6

8

10

12

14

+5VDC*

8765432

1

131211109

Line**

VAC

Line**

VAC

Line**

VAC

Steam Heating Element

Door

J15

3

C

NO

2

W2

1

Wht

Red

Blk

Blk

Door Opening

Motor Assy.

(M9 / Mll Only)

Switch

Motor

(Line Voltage

)

Line

VAC*

Line

VAC

NO

C

NC

C

(Motor Lever Arm

Depresses Switch

to open position)

(Energized for

12 secs. [1 1/2 rpm]

to 30 secs. [1 rpm] )

Wht

Red

SW1 Settings

Switch

1 On for Service Diagnostics

2 On for Model Designation

3, 4, 5 Not Used, leave Off

6 On for Communication Port

hook-up to computer.

7 Off-English, On-Metric

8 Not Used, Leave Off

4

3

2

1

8

7

6

5

ON

Test Points (TP)

TP2 - TP1 12 VDC supply to

K1 - K5 relay coils.

TP2 - TP3 5 VDC supply to

low voltage circuit

components.

TP2 - TP4 5 VDC supply to Temp.

& Pressure Sensors.

TP2 - TP5 5 VDC supply to Printer.

* Constant Voltage

** Voltage Present Only

During Component Operation

Note:

Disconnect plug connector

when checking voltage.

(*) NOTE:

Some Solenoid Coils may be

marked FWR (Full Wave Rectified)

Use the Mohms scale to measure

these coils. If reading is 0.2

Mohms or above, coil is GOOD.

If OL is displayed, coil is BAD.

115 VAC

Resistances (Ohms) Cold

(+ / - 10%)

Door Opening

Motor

(+/- 7.5%) 6000 - 9300 ohms

Fill Solenoid Note (*) M ohms

Air Solenoid Note (*) M ohms

Vent Solenoid Note (*) M ohms

Heating Element 10 Ohms

Electrical Requirements

104 to 127 VAC

50 / 60 Hz

Dedicated 15 Amp

Supply Circuit

Fuses

F1: 0.250 Amp, 250 V.

Slow Blow, 1/4"x1 1/4"

F2: 15 Amp, 250 V.

Fast Acting, 1/4"x1 1/4"

Electrical Requirements

207 to 250 VAC

50 / 60 Hz

Dedicated 15 Amp

Supply Circuit

230 VAC

Fuses

F1: 0.125 Amp, 250 V.

Slow Blow, 5 x 20mm

F2: 8 Amp, 250 V.

Fast Acting, 5 x 20mm

Resistances (Ohms) Cold

(+ / - 10%)

Door Opening

Motor

(+/- 7.5%) 13K - 16K ohms

Fill Solenoid Note (*) M ohms

Air Solenoid Note (*) M ohms

Vent Solenoid Note (*) M ohms

Heating Element 38 Ohms

Figure 2-2. Schematic

Rev. 9/25/03

Return To Table of Contents

Loading...

Loading...