SECTION I

GENERAL INFORMATION

© Midmark Corporation 2002 SF-1803 Page 1- 2 Printed in U.S.A.

Air Valve

A Normally Closed

Valve that, when energized open,

removes air from chamber expelling it into the reservoir

thru the condensing coil during operation. Controlled by

main control p.c. board. Valve is located on top, back of

pressure vessel.

Temperature Probe

Temperature probe monitors internal chamber tempera-

ture during operation and transmits it back to main p.c.

board. The probe is located in the back of the chamber.

Main Control P.C. Board

Contains the program logic, and various connections to

send and receive data to operate the various programs.

SW1 dip switch assembly is located on the left side of

the board. Service Diagnostics, and various display

options can be accessed by changing switch positions.

Fuses F1 and F2 protect the main control p.c. board.

Hi-Limit Switches

Controls power to heating elements and various compo-

nents should overheat conditions exist.

Two normally closed, bimetal, thermostats that automat-

ically opens contacts at 425°F (218°C) to 475°F (246°C)

removing power to heating elements.

They automatically reset to the closed position at 325°F

(163°C) to 375°F (191°C).

They are located on lower

, outside surface of chamber.

Water Level Sensor

Located in back of chamber, it monitors the water level

during the FILL cycle. When the water level reaches the

sensor, a circuit is completed which signals the main

control P.C. board to remove power from the Fill Valve

solenoid, closing the valve.

Fill Valve

Fill Valve is a Normally Closed

valve. The Door Interlock

switch must be closed to operate the Fill Valve. When

the START key is depressed the Fill Valve solenoid is

energized. The valve opens

, allowing water to enter the

chamber. When water reaches the Water Level Sensor

a circuit is completed, removing power from the Fill

Valve solenoid coil, closing the valve.

Vent Valve

Vent Valve is a Normally Open

valve controlled by the

main control P.C. board. When K4 contacts on the Main

P.C. Board close, the solenoid of the Vent Valve ener-

gizes, closing

the valve. In the open position, the valve

vents back thru the condensing coil in the reservoir.

Display / P.C. Board

Operation and Service Diagnostic messages are

viewed though use of a liquid crystal display (LCD) on

the front of the top cover.

Heating Element

Submersible, tubular, 1425 watt (115 VAC) or 1500 watt

(230 VAC), heating element used to generate steam for

the sterilizer.

During the Heatup, Sterilization and Dry cycles the tem-

perature probe monitors internal chamber conditions,

sending signals back to main control P.C. board which

controls On / Off cycling of heater.

Pressure Relief Valve

The ASME approved Safety valve opens to vent the

chamber should pressure inside chamber reach 40

PSIG [+/-2 PSI] (275.8 kPa). The steam is vented out

below base of sterilizer.

Reservoir Tank w/ Condensing Coil

Retains supply of distilled water for operation. During a

cycle air and steam is discharged from the chamber

back thru the condensing coil into the reservoir. An

equalizer tube, located on top of the reservoir, prevents

pressure differential between the two chambers in the

reservoir.

Filter Screens

Fine, stainless steel, mesh screens located in the back

and bottom of chamber for filtering particles from the

system. The Filters should be cleaned monthly or more

often depending on use

Pressure Vessel

Includes chamber and door assembly which are ASME

certified. Never attempt to make repairs on the pressure

vessel.

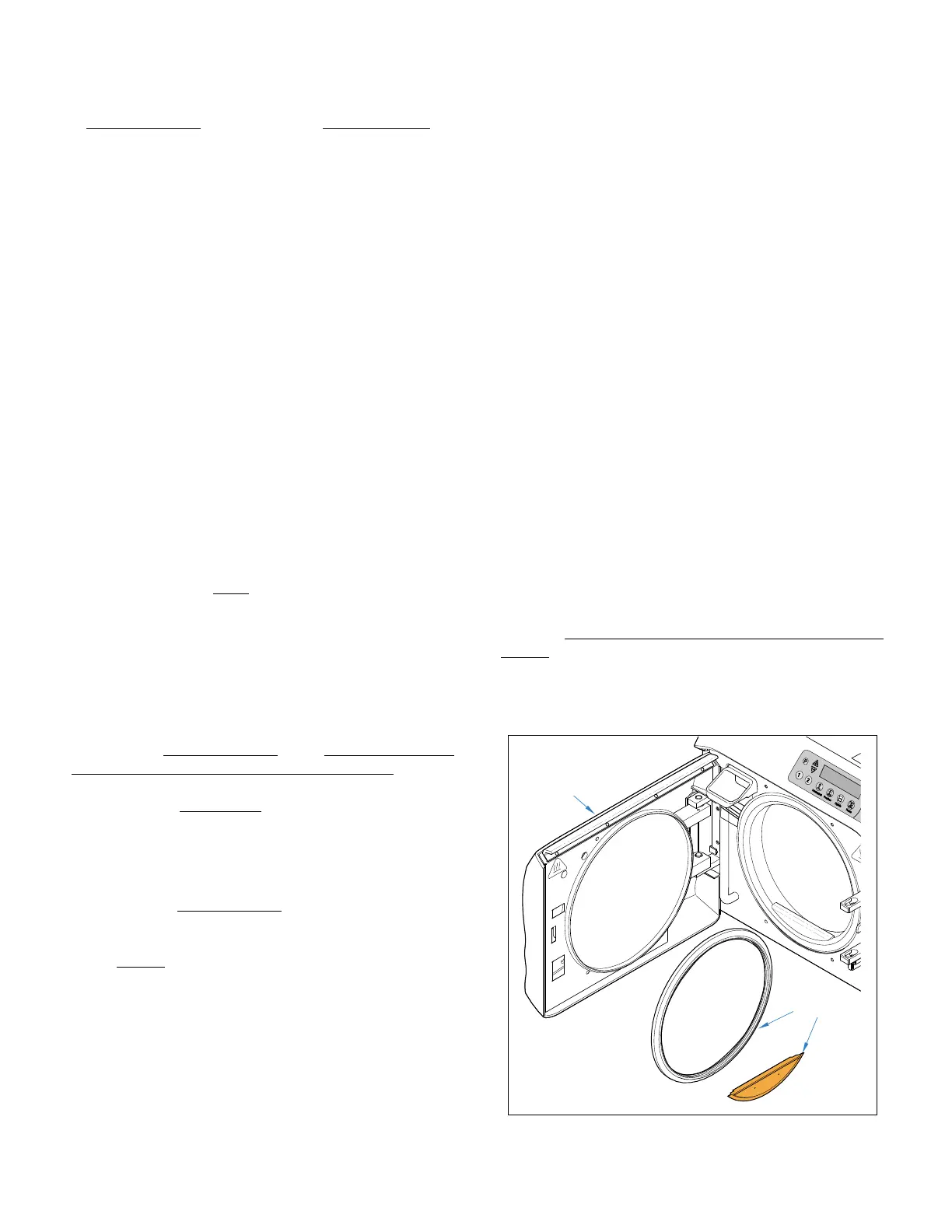

Door and Dam Gaskets (Fig. 1-2)

Seals door when in latched position to prevent pressure

from escaping around door during operation.

MA598904i

STEAM BLOCK

GASKET

DOOR & DAM

GASKETS

Figure 1-2.

Rev. 8/04/03

Return To Table of Contents

Loading...

Loading...