Milestone Srl MA213-003 – DMA-80 EVO – User Manual

150

2. CALIBRATION FOR ULTRATRACE LEVEL 0,1 ppb

Below is reported the procedure to calibrate the system a ultratrace level. Calibration has to begin with a

blank and at least one point lower than 0,1 ppb.

In order to maintain a good linearity of the calibration, we reduce the working range of the cell 0 to 1 ng.

The ultra-trace calibration has to be prepared as follow:

- Prepare fresh standard solutions according to the customer working range. It is recommended to only

use daily prepared standards in glass flask, perfectly cleaned. We suggest using a Standard Stock

solution with a concentration lower than 1000 ppm, such as 10 ppm, to avoid a lot of dilutions.

- Standards have to be stabilized with HCl (2% v/v), in order to avoid mercury evaporation. Use ultrapure

grade HCl.

- Always use 0.3 mL of standard. The use of 0.3 mL instead of 0.1 mL volume to enhance the data

reproducibility

- The first calibration point has to be a real blank with the same volume (0.3 mL) and matrix (water with

2% v/v of HCl) used for all the other points of the calibration. The ABS value of the first calibration point

must be less than 0,0040 in cell 0.

- Perform at least two replicates for each standard

- Calibrate up to 1 ng and then activate the Ultra-trace function

3. PRACTICAL EXAMPLE OF ULTRATRACE CALIBRATION

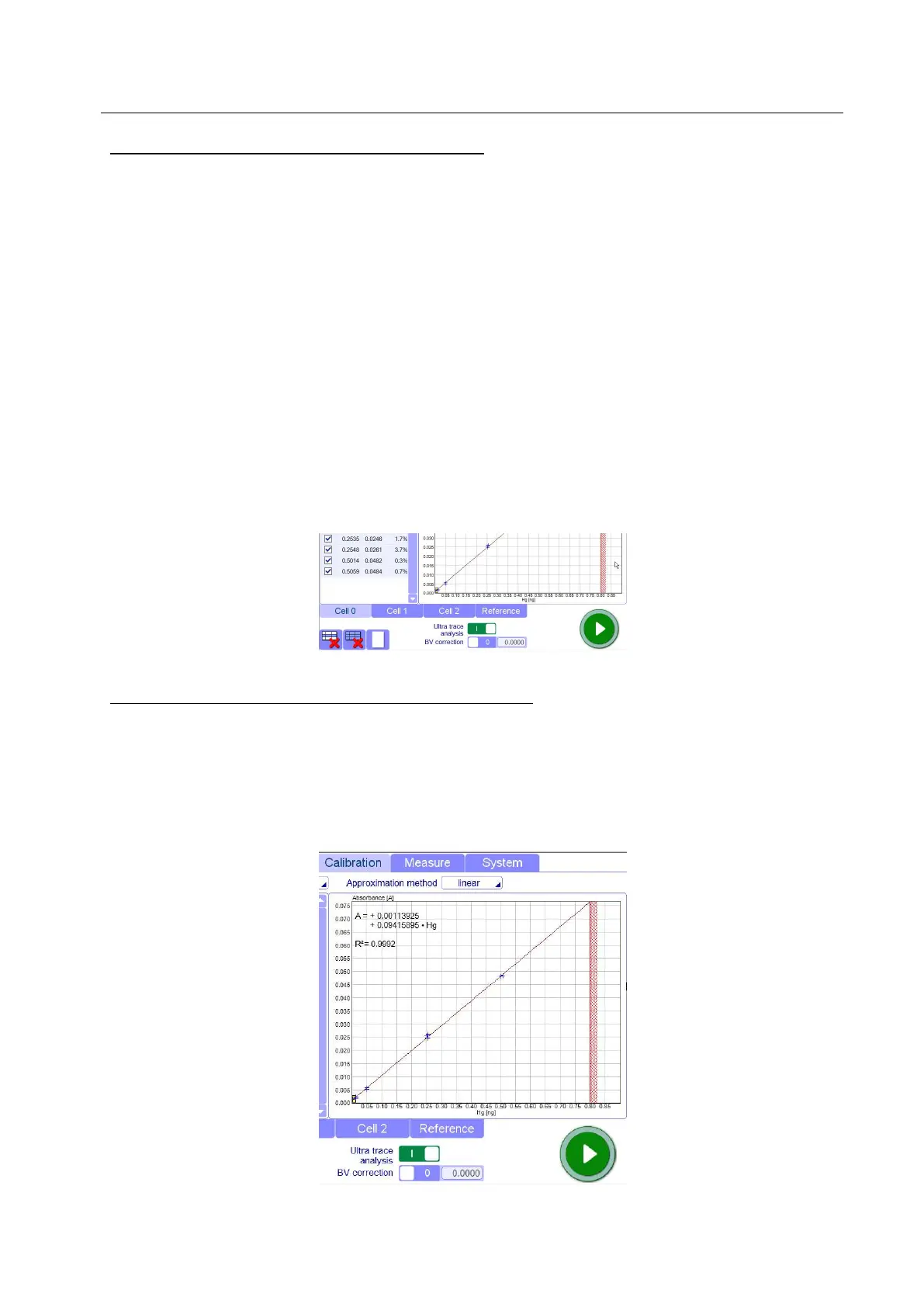

Below is reported an example of ultra-trace calibration. The target of this calibration is to provide a curve

suitable to analyze samples with a mercury level from 0.1 ppb.

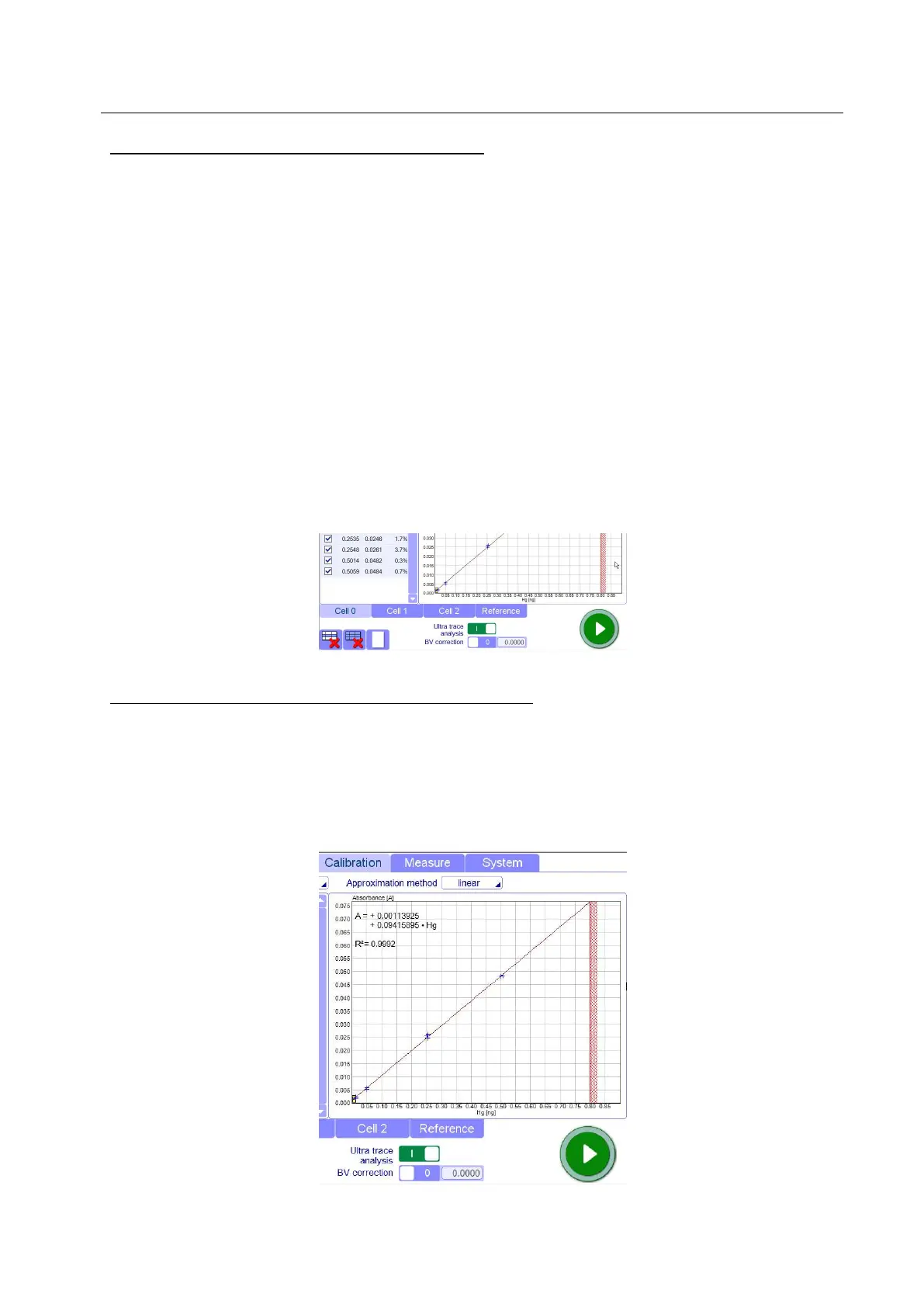

In this specific example we have made 4 standards from 0.0125 ng up to 0.5 ng, each of them in triplicate

in order to show the reproducibility and the stability of the system at that range. We use 0.3 ml both for

standards and QC test. Once the last point of the calibration is done. Activate the Ultra-trace function.

These are the results we got:

Loading...

Loading...