Milestone Srl MA213-003 – DMA-80 EVO – User Manual

153

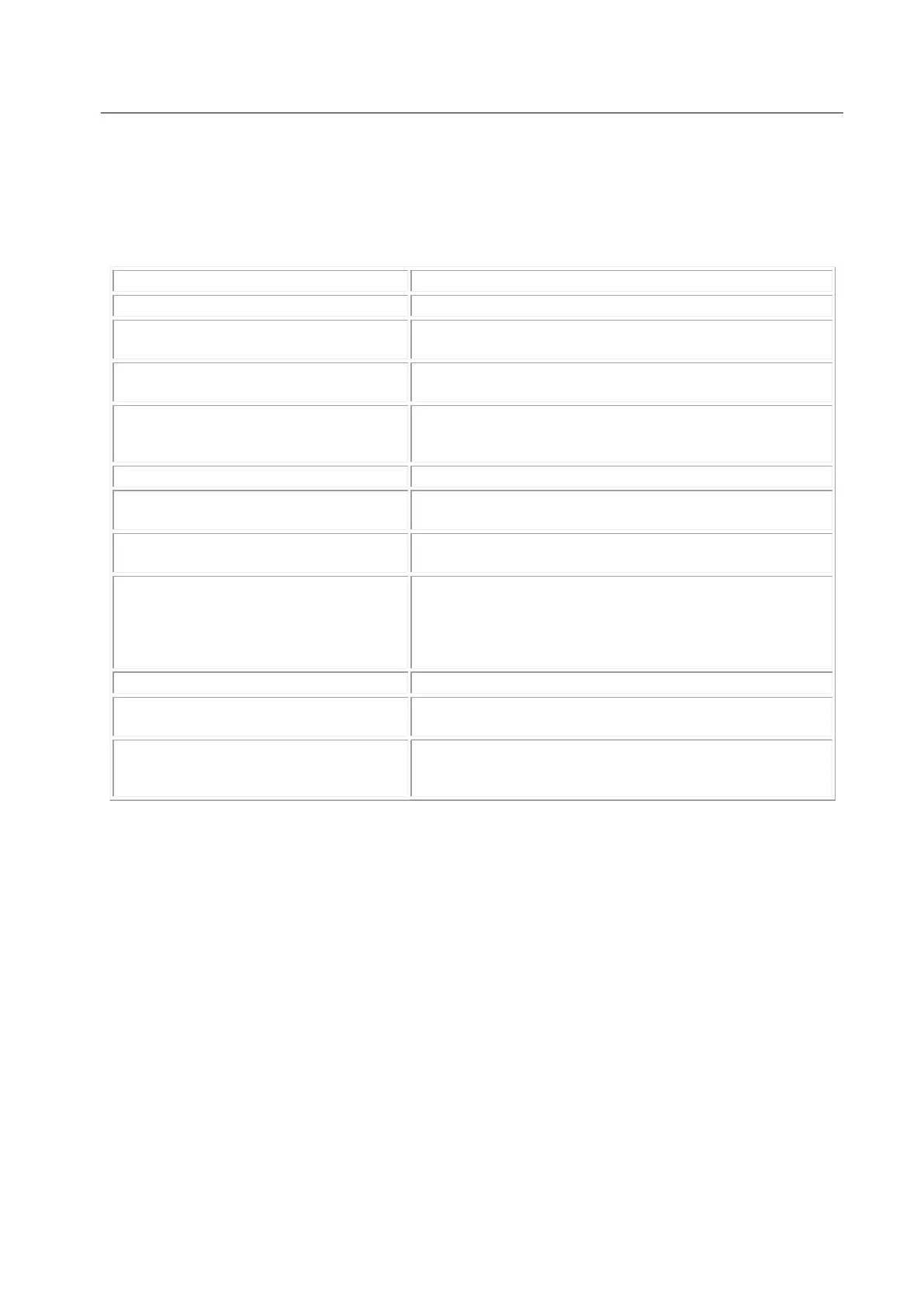

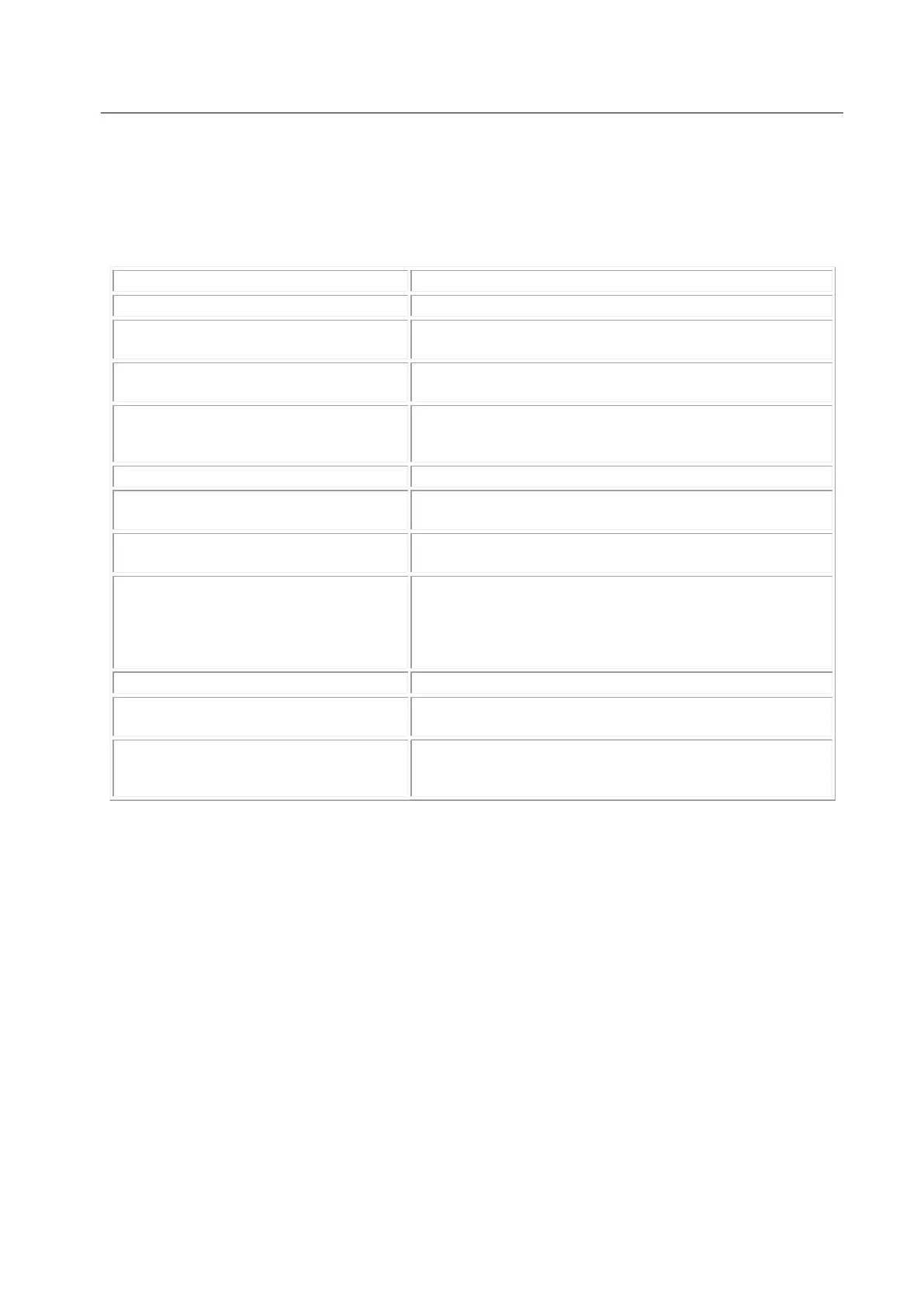

8.5.5 How to increase the reproducibility

After calibration, the reproducibility of the unit should be lower than <1.5% for 5 measurements with

0.1 ml of a solution of 100 ppb ug/Kg (10ng).

If this goal is not achieved with your samples, the cause may be one or more of the following :

Solid/liquid sample contaminated

Repeat the test with new sample.

Solid sample with non-homogeneous

Mix well and increase the sample amount.

Solid/liquid sample with low amount of

Mix well solid and use pre-concentration step up to

satisfactory results.

Old standard liquid solution/liquid

solution with precipitated due to not

Prepare fresh standard liquid solution.

Check balance calibration / Pipette calibration.

DMA-80 unit is not cleaned after high

concentration or “over range”

Cleaning procedure up to blank absorbance < 0.0030

Process parameter too short Increase: waiting (purge) time/ drying time/ decomposition

time.

Leakage of oxygen through the

silicone joint between

cuvette/amalgamator,

amalgamator/catalyst or catalyst/flange

Repair as shown in the “Maintenance of

The DMA-80” manual.

Use only O

2

, 99.50% pure for research, or replace supplier.

The catalyst and or/and amalgamator

Change catalyst and amalgamator and repeat calibration.

Environment contaminated Cleaning procedure up to blank absorbance < 0.0010, if

after this the contamination persists, transfer unit to another

laboratory.

8.6 HOW TO WORK WITH UNKNOWN SAMPLES

Unknown samples can contain high concentrations of Hg, so in order to avoid contamination of the catalyst

we suggest developing the application with a minimum quantity of sample (<5 mg) and then increasing

according the result.

Note: 1500 ng is our highest absolute value of mercury detectable.

For solid samples with concentrations of Hg higher than our range, it is possible to do a premix from 1:1 to

1:200 with inert material, such as previously decontaminated alumina.

For liquid samples with high Hg concentration, it is possible to do a dilution using the same matrix.

8.6.1 How to work with non-homogeneous samples

Non-homogeneous samples can result in poor reproducibility of the results. It is possible to increase the

performance with a sample preparation procedure.

The problem is due to non-homogeneous distribution of Hg in the matrix, or to different sizes of the same

sample—especially for inorganic samples such as soil, sediment, ore, rocks, plastic, etc.

To solve the first problem, mixing well should suffice. For the second problem, you need to reduce the

sample’s particle size to a powder form, normally below 100 um.

Pre-concentration steps may work as an alternative solution.

Loading...

Loading...