Milestone Srl MA213-003 – DMA-80 EVO – User Manual

95

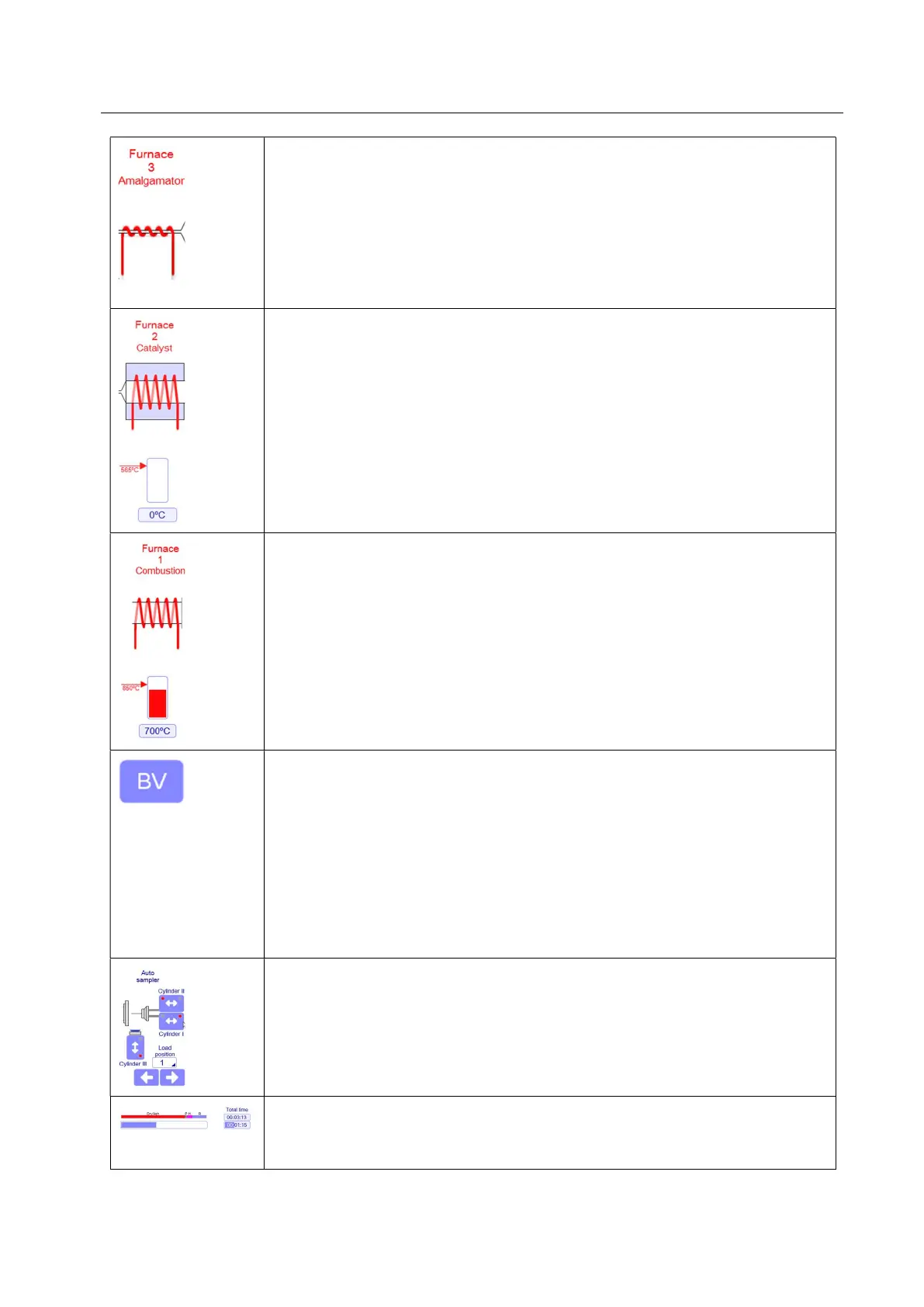

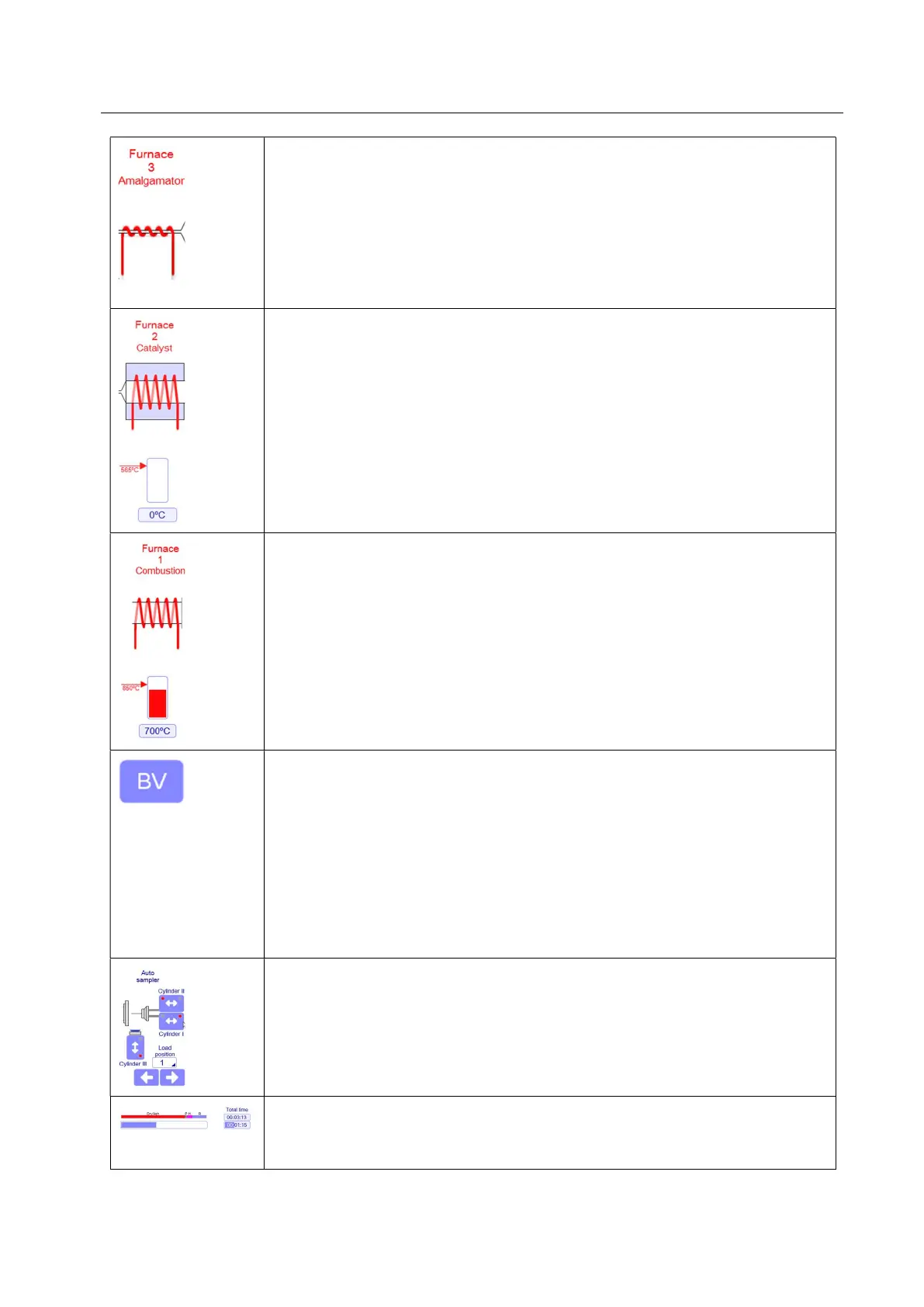

Amalgamator furnace: the temperature of the amalgamator is not displayed

because no sensor is present. The heating is supplied by the electronic mother

board following proper steps of dedicated times and powers.

Purpose of the amalgamator coil is to keep the amalgamator tube at the stand-

by temperature of 170°C/150°C and then to quickly heat it up to 850°C. The first

temperature is necessary to avoid water condensation and retain of organic

residues in the amalgamator tube; the higher temperature is necessary to

release at the same time the mercury previously “trapped” in the amalgamator.

Catalyst furnace: here it is reported the temperature of the heating coil that

covers the part with material of the catalyst tube.

Purpose of the catalyst oven is to keep the temperature of the tube stable, which

is necessary for its optimal functioning. Inside the catalyst tube, mercury coming

from the sample is converted in metallic mercury and the reaction products

generated during the sample decomposition are neutralized.

Combustion furnace: here it is reported the temperature of the heating coil that

covers the empty part of the catalyst tube.

Purposes of this furnace are moisture removal from solid samples, bulk

evaporation from liquid samples and final decomposition.

BV function: pressing this icon, the corresponding furnace will be heated.

- BV furnace 3 Amalgamator: used to clean the amalgamator. The cleaning is

automatically registered in the sample list and documented.

- BV furnace 1 Combustion: used to start a blank value measurement. The purity

of the system is tested, without using any boat. The cleaning is automatically

registered in the sample list and documented.

The used method is “BV-Method”. Any method can be identified by this name.

The best would be to define the standard method as “BV-Method”. Alternatively,

it will be used a setup method.

Autosampler: here, the position of pneumatic cylinders and autosampler plate

is shown. Pressing these different icons, it is possible to move the cylinders and

the autosampler plate.

Analysis time: Once started a measurement, the total time will be displayed

(Format hh:mm:ss). Independent on the time, in automatic mode, the estimated

time is constantly updated during the sample processing.

Loading...

Loading...