OM-278174 Page 27

F

Complete Parts List is available at www.MillerWelds.com

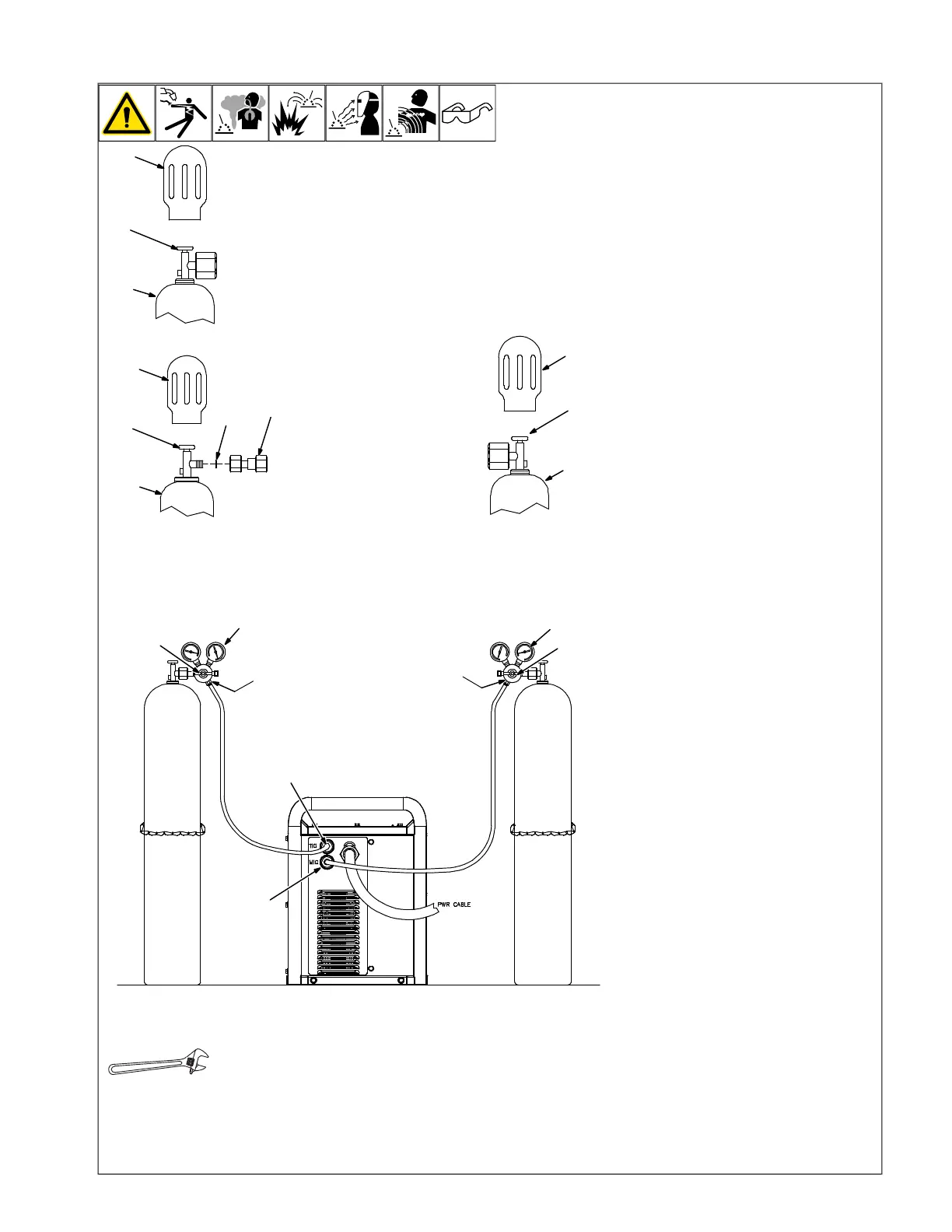

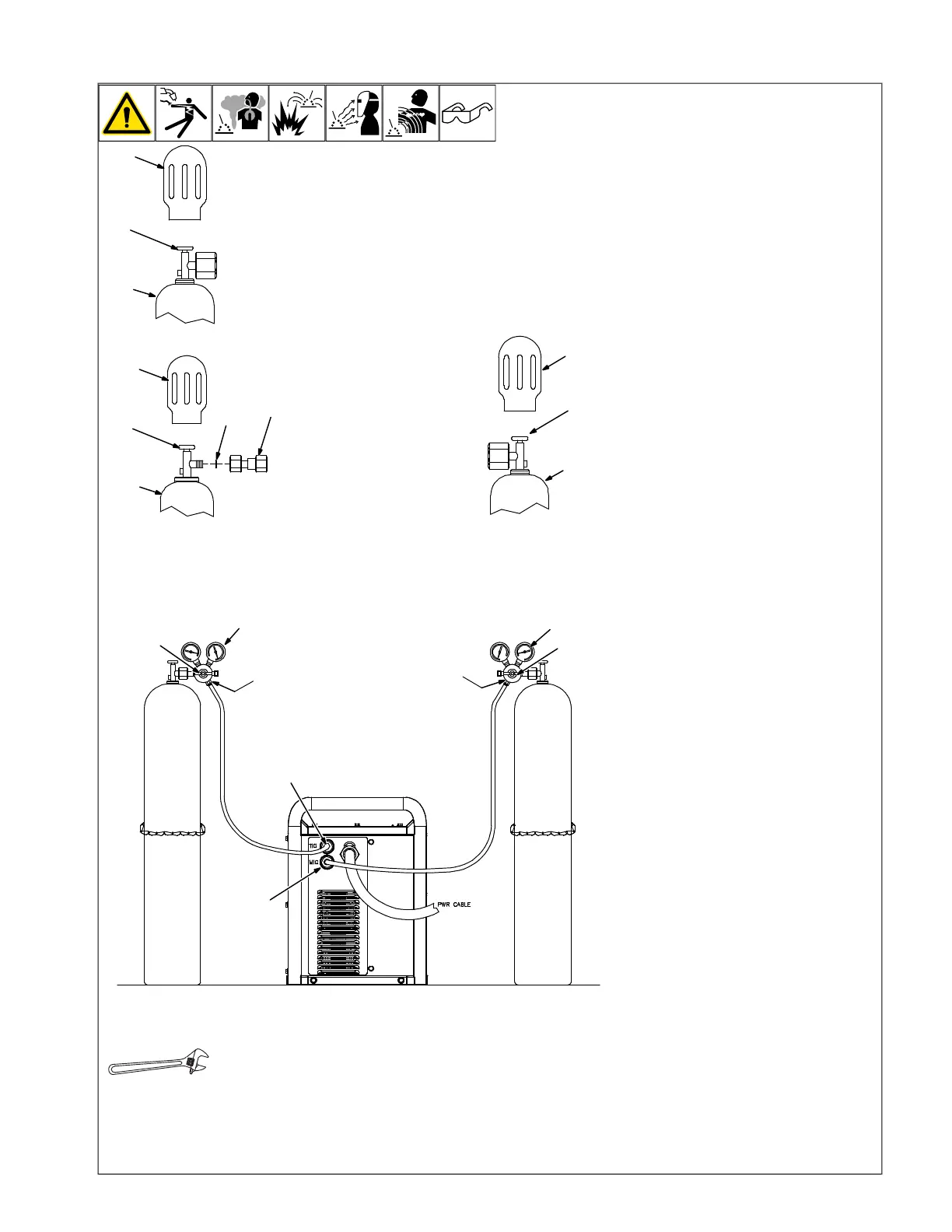

5-13. Connecting Shielding Gas Supply

Ref. 804 654-A / 275168A / 280272C

1

2

3

Argon Gas

CO

2

Gas

1

2

3

Mixed Gas

1

2

3

10

9

8

4

5

4

5

8

6

7

MIGTIG

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

so

lderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

Obtain gas cylinder and chain to running

gear, wall, or other stationary support so cyl-

inder cannot fall and break off valve.

1 Cap

2 Cylinder Valve

Remove cap, stand to side of valve, and

open valve slightly. Gas flow blows dust and

dirt from valve. Close valve.

3 Cylinder

4 Regulator/Flowmeter

Install Regulator/Flowmeter so face is

vertical.

5 Regulator/Flowmeter Gas Hose

Connection

6 Welding Power Source CO

2

And Mixed

Gas Hose Connection

7 Welding Power Source Argon Gas Hose

Connection

Connect gas hose between regulator/flow-

meter gas hose connection, and the appro-

priate fitting for the gas type on rear of

welding power source.

8 Flow Adjust

Typical flow rate for shielding gas is 20 to

30 CFH (cubic feet per hour). Check wire

manufacturer's recommended flow rate.

9 CO

2

Adapter (Customer Supplied)

10 O-Ring (Customer Supplied)

Install adapter with O-ring between regula-

tor/flowmeter and CO

2

cylinder.

Loading...

Loading...