OM-278174 Page 60

F

Complete Parts List is available at www.MillerWelds.com

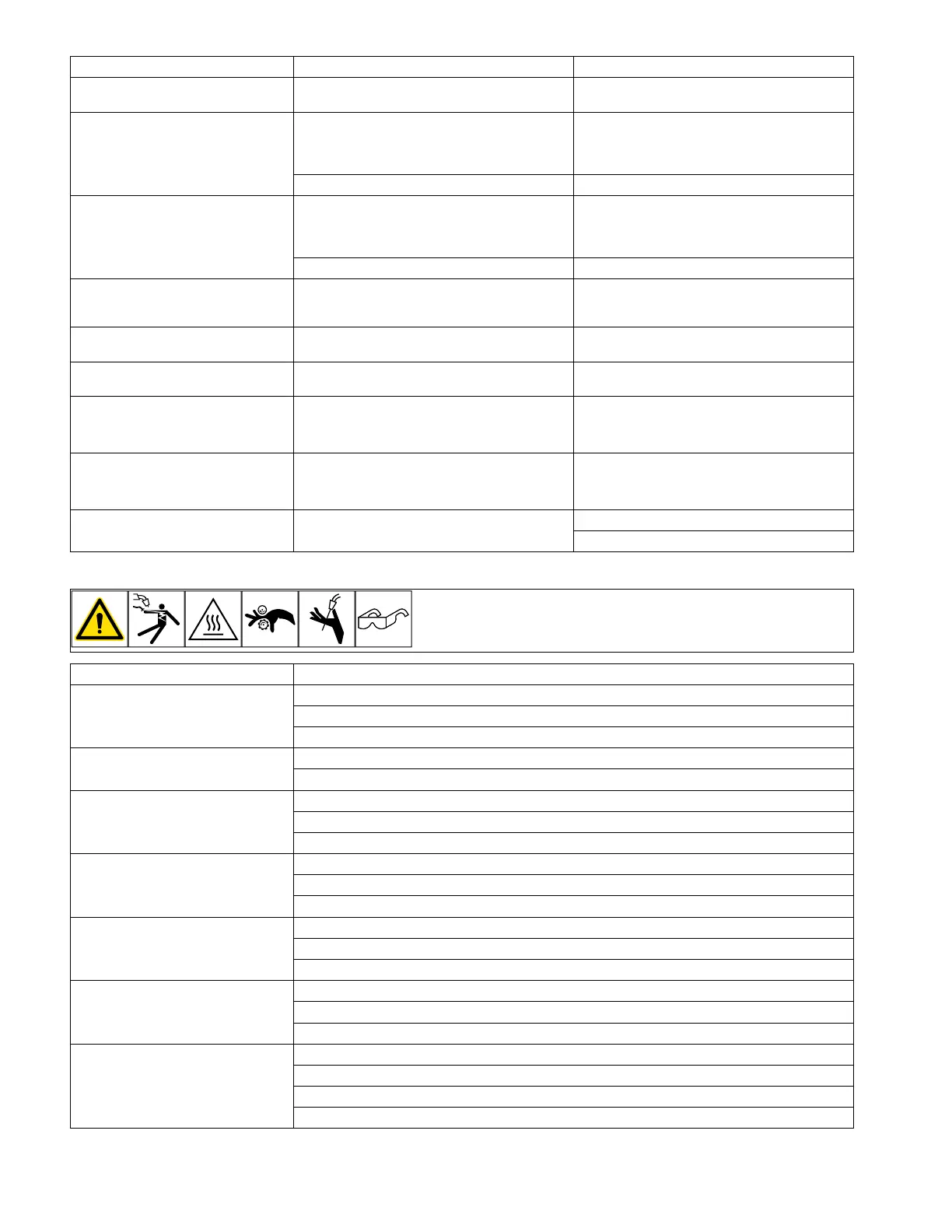

Message Error Remedy

Free tungsten to clear error

Tungsten has contacted workpiece for more than

five seconds without starting an arc.

Cable error — Connect wire feed

housing cable to clear error.

A process that requires a welding gun to be at-

tached to the internal motor is selected, but the

wire feed housing cable is not attached to the

positive or negative stud of the power source.

Connect wire drive assembly cable to either the

positive or negative stud, or select a different

process.

The control board is damaged. Contact authorized service location

Cable error — Wire feed housing ca-

ble is touching electrode or work.

A process that does not require a welding gun to

be attached to the internal motor is selected, but

the wire feed housing cable is attached to the

positive or negative stud of the power source.

Remove wire drive assembly cable from either

the positive or negative stud, or select a different

process.

The control board is damaged. Contact authorized service location

Transformer Saturation error — Re-

lease trigger to clear OR cycle power

to clear.

Main transformer has detected an overcurrent

condition.

Cycle power to clear error. If this problem per-

sists, contact Miller Electric Mfg. authorized serv-

ice location.

Missing UI Membrane Switch Overlay. UI membrane is not detected as being plugged

in.

Contact Miller Electric Mfg. authorized service

location.

UI Membrane Switch Overlay doesn’t

match arc controller program

Detected UI membrane is not detected as match-

ing the type reported by the main control board.

Contact Miller Electric Mfg. authorized service

location.

Over Voltage Protection Trip

Cycle power to clear error

System has detected an over voltage condition

on the output.

Contact Miller Electric Mfg. authorized service

location.

Secondary Current Sensor Fault

Check connection

Harness is not detected for secondary current

sensor..

Contact Miller Electric Mfg. authorized service

location.

CAN Data Version Incompatible The UI and the Control are not compatible, per-

haps due to a partial firmware upgrade.

Restart the Firmware upgrade process.

Contact authorized service location.

7-6. Troubleshooting

Trouble Remedy

No weld output; unit completely

inoperative.

Place line disconnect switch in On position.

Check and replace line fuse(s), if necessary, or reset supplementary protector.

Be sure power cord is plugged in and that receptacle is receiving input power.

No weld output; unit is on. Check and secure loose weld cable(s) into receptacle(s).

Check and correct poor connection of work clamp to workpiece.

Erratic or improper welding arc or

output.

Use proper size and type of weld cable (see your Distributor).

Clean and tighten weld connections.

Verify electrode polarity; check and correct poor connections to workpiece.

Fan not operating. Unit not warmed up enough to require fan cooling.

Check for and remove anything blocking fan movement.

Have Factory Authorized Service Agent check fan motor and control circuitry.

Stick welding problems; Hard starts;

poor welding characteristics; unusual

spattering.

Use proper size and type of electrode.

Verify electrode polarity; check and correct poor connections.

Make sure remote control cable is not connected.

TIG welding problems; Hard starts;

poor welding characteristics; wander-

ing arc; spattering problems.

Use proper size and type of tungsten.

Use properly prepared tungsten.

Verify electrode polarity.

TIG welding problems; Tungsten elec-

trode oxidizing and not remaining

bright after welding.

Shield weld zone from drafts.

Check for correct type shielding gas.

Check and tighten gas fittings.

Verify electrode polarity.

Loading...

Loading...