OM-278174 Page 29

F

Complete Parts List is available at www.MillerWelds.com

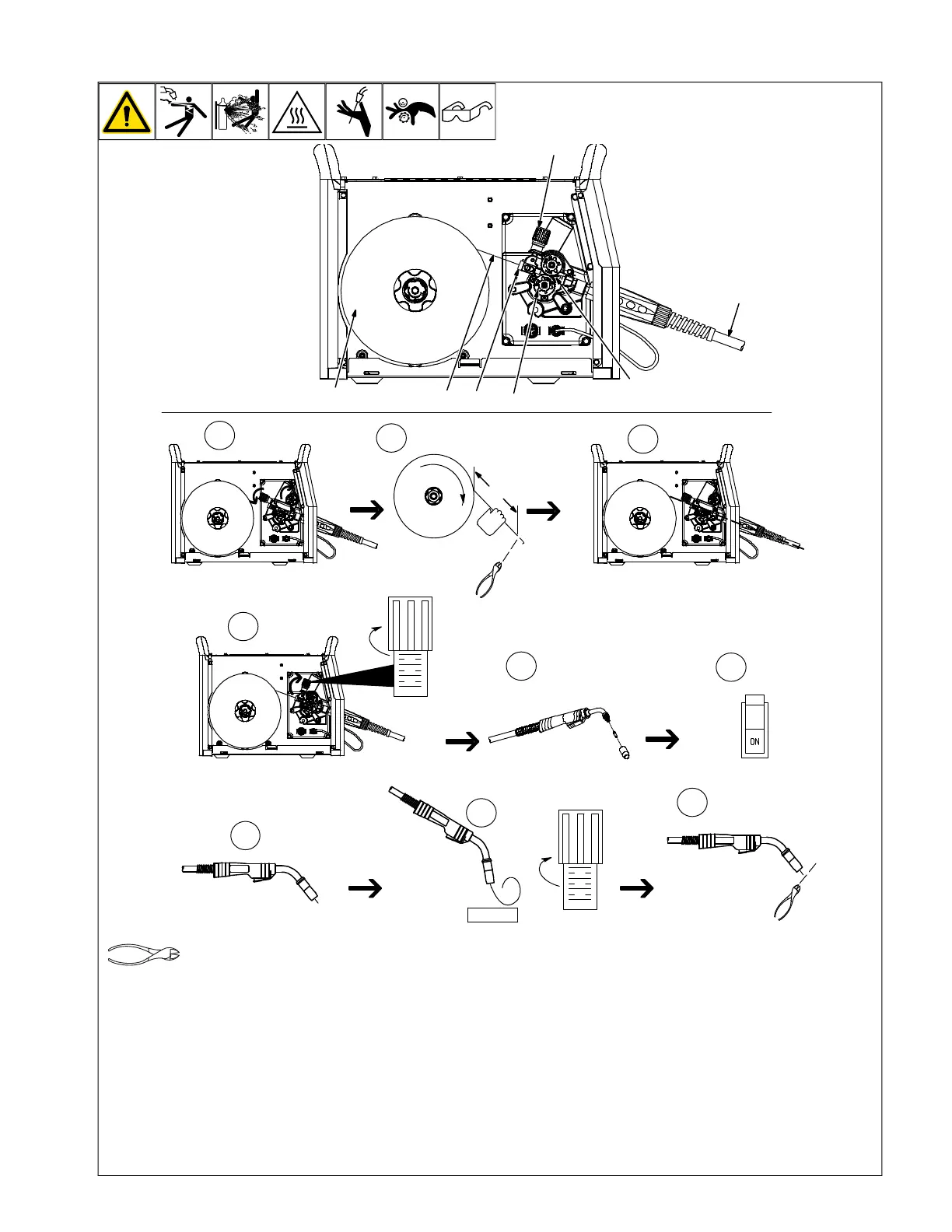

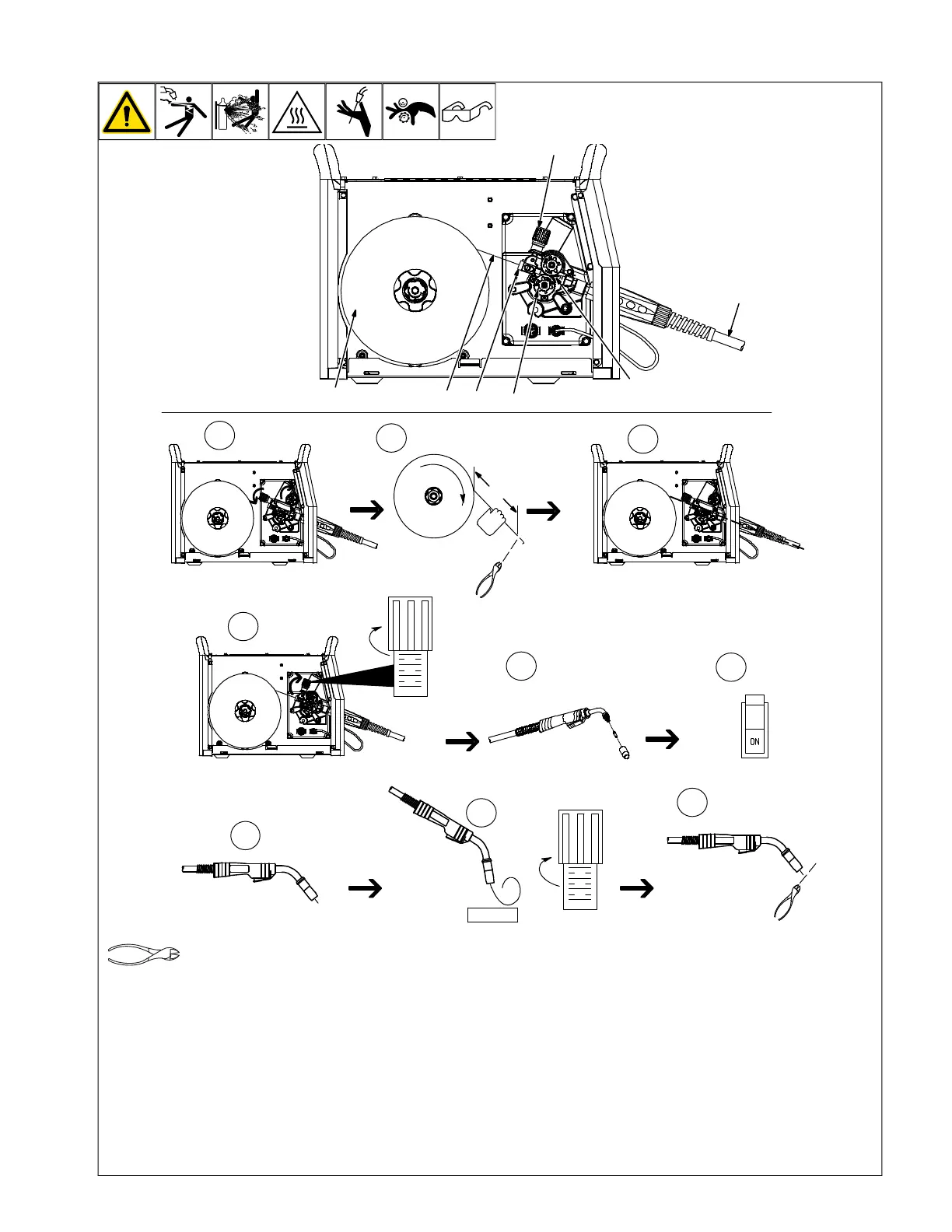

5-15. Threading Welding Wire

WOOD

1

2

3

4

1

2

3

4

6 in.

(150 mm)

1

2

3

4

5 6

7

8

9

7

4

5

2

1

3

6

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

s

tripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

1 Wire Spool

2 Welding Wire

3 Inlet Wire Guide

4 Pressure Adjustment Knob

5 Drive Roll

6 Outlet Wire Guide

7 Gun Conduit Cable

Lay gun cable out straight.

Step 1. Open pressure assembly.

Step 2. Pull and hold wire; cut off end.

F

Hold wire tightly to keep it from

unraveling.

Step 3. Push wire through guides into gun;

continue to hold wire.

Step 4. Close and tighten pressure assem-

bly, and let go of wire.

F

Use pressure indicator scale to set a

desired drive roll pressure. Begin with

a setting of 2. If necessary, make addi-

tional adjustments after trying this ini-

tial setting.

Step 5. Remove gun nozzle and contact tip.

Step 6. Turn On.

Step 7. Press gun trigger until wire comes

out of gun. Reinstall contact tip and nozzle.

Step 8. Feed wire to check drive roll pres-

sure. Tighten knob enough to prevent

slipping.

Step 9. Cut off wire. Close and latch door.

Loading...

Loading...