OM-278174 Page 35

F

Complete Parts List is available at www.MillerWelds.com

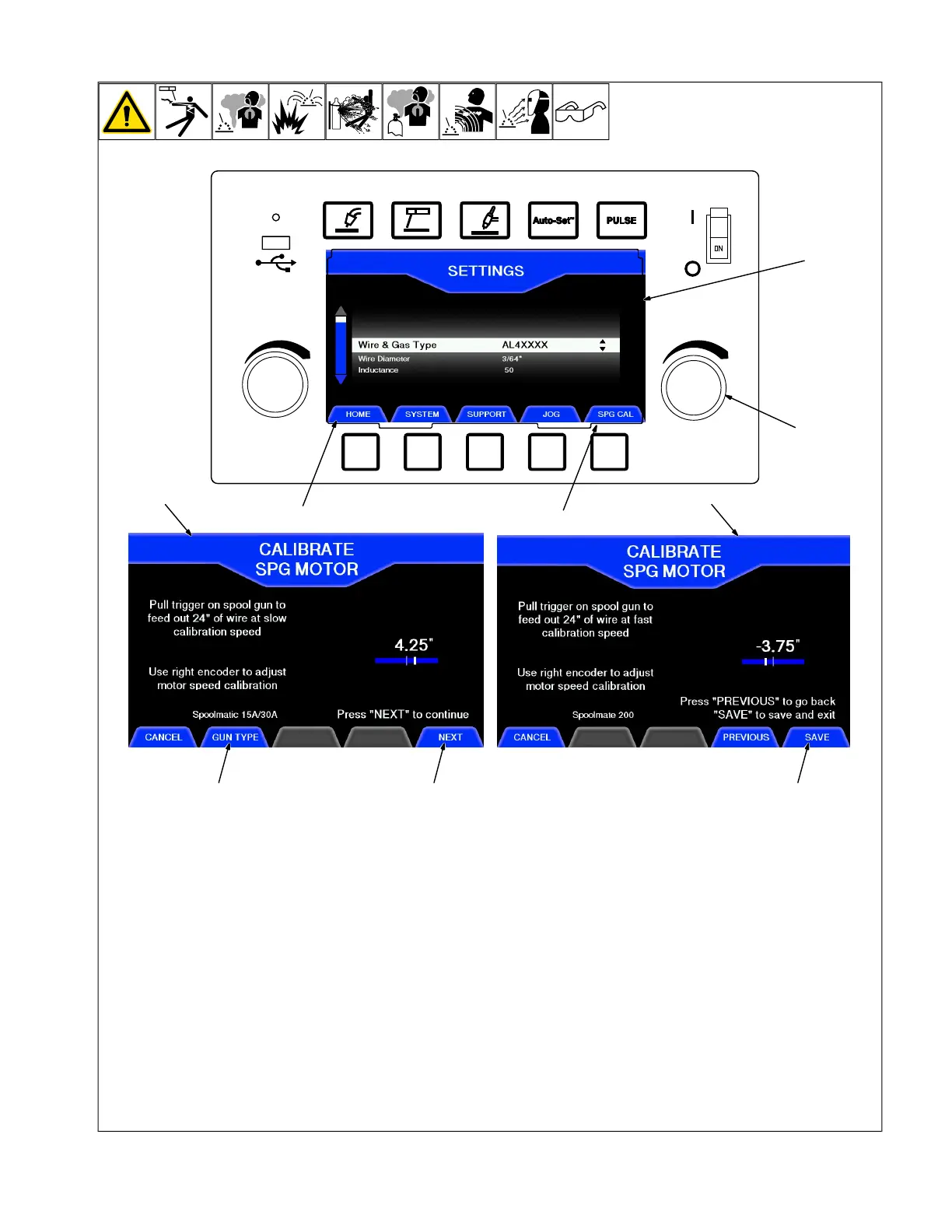

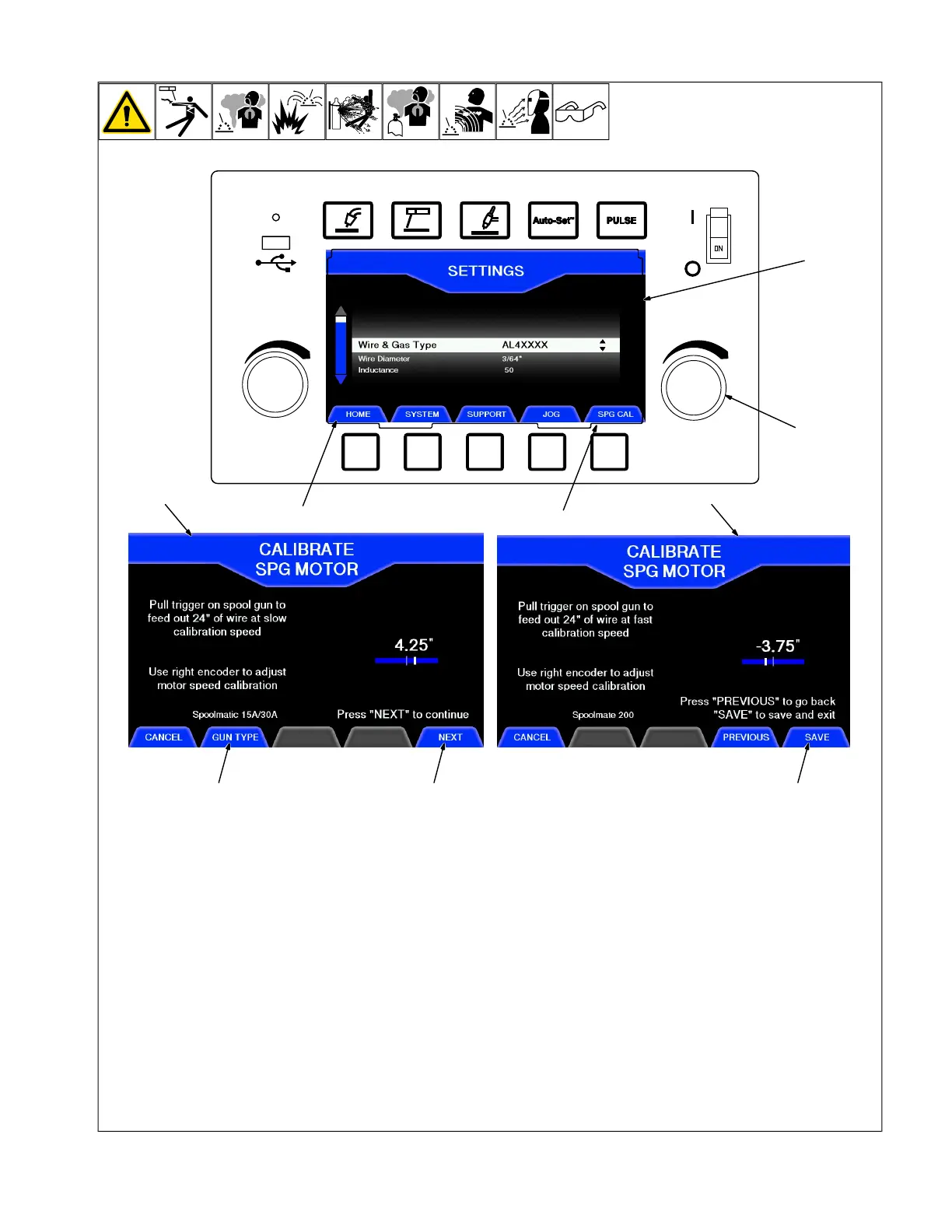

5-21. Calibrating Spoolgun

F

Spoolmatic 15/30A and Spoolmate

200 motors are unique to this welding

power source. Motor calibration is nec-

essary any time a different Spoolmatic

15/30A or Spoolmate 200 is connected

to the Multimatic 255.

1 Settings Menu

2 Slow Speed Calibration Menu

3 Fast Speed Calibration Menu

4 Home

5 Spg Cal (Spoolgun Cal)

6 Right Knob

7 Gun Type

8 Next

9 Save

Connect spoolgun to unit. Cut wire flush at

nozzle

Follow instructions in Section 6-5 to enter

the setup menu.

F

SPG CAL will only be displayed as the

fifth tab when a spoolgun is

connected.

Press SPG CAL to access slow speed cali-

bration menu.

Press Gun Type to select the spoolgun

being used.

To begin the slow speed calibration, pull the

spoolgun trigger. The wire will feed and au-

tomatically stop.

Cut wire flush at nozzle and measure run-

out. If wire length is not 24 in., use right knob

to enter the amount that the wire was short/

long.

Pull spoolgun trigger again to verify the ad-

justment. Repeat these steps until satisfied

with accuracy.

Press Next to access fast speed calibration.

To begin the fast speed calibration, pull the

spoolgun trigger. The wire will feed wire and

automatically stop.

Cut wire flush at nozzle and measure run-

out. If wire length is not 24 in., use right knob

to enter the amount that the wire was short/

long.

Pull spoolgun trigger again to verify the ad-

justment. Repeat these steps until satisfied

with accuracy.

Press Save to complete the calibration pro-

cedure and be returned back to the settings

menu.

Press Home to return to weld mode.

Loading...

Loading...