ENGLISH

OM-225 389 Page 11

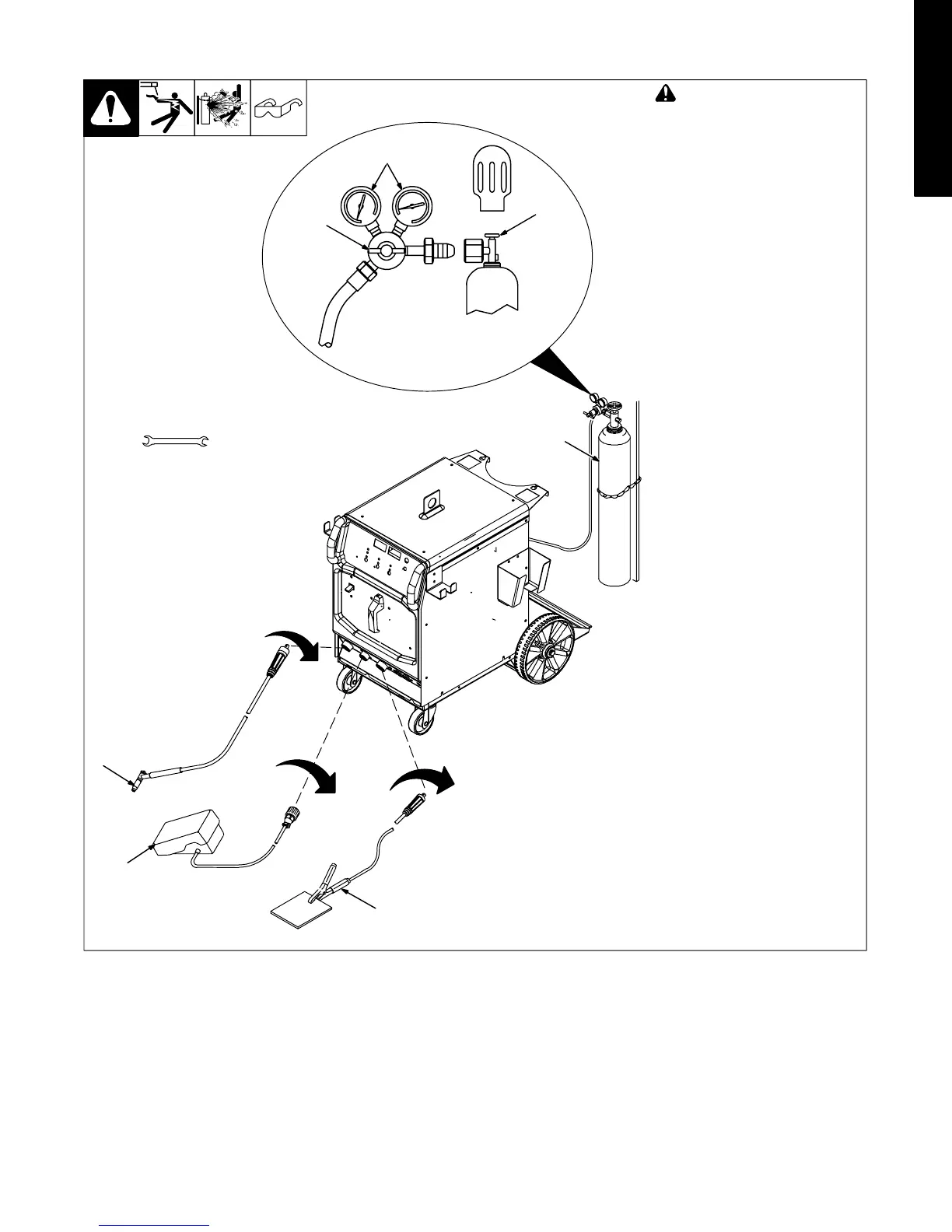

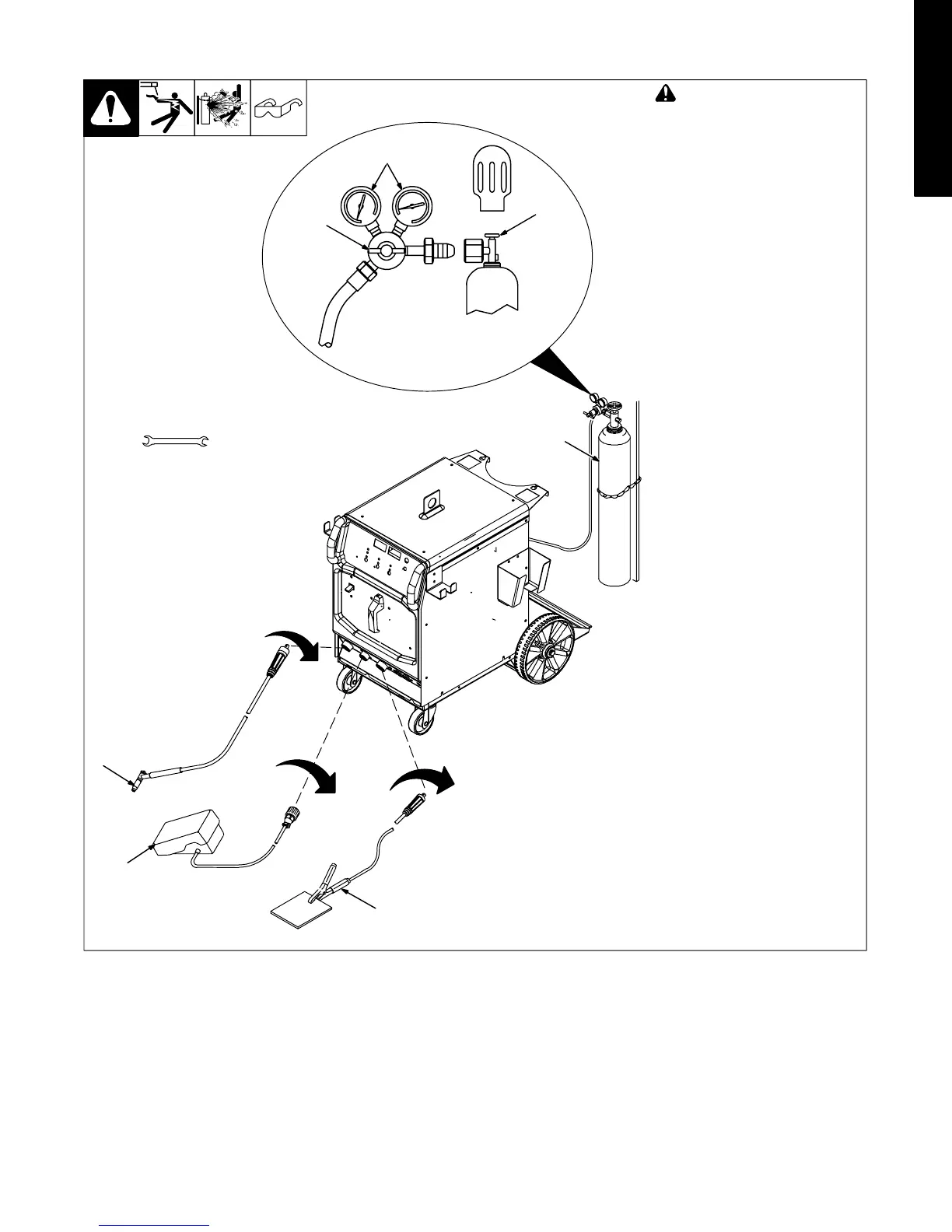

2-13. Typical TIG Connections

! Turn off power before mak-

ing connections.

1 Remote Foot Control

A customer supplied remote finger-

tip control may also be used.

2 Torch

3 Work Clamp

Connect remote control, torch, and

work clamp to receptacles as

shown.

4 Cylinder

Chain or secure cylinder to running

gear, wall, or other stationary

support.

5 Cylinder Valve

Open valve slightly so gas flow

blows dirt from valve. Close valve.

6 Regulator/Flow Gauge

Install so face is vertical.

7 Flow Adjust

Typical flow rate is 20 cfh (cubic feet

per hour) (9.4 L/min).

After activating remote control, 0.2

seconds of gas preflow will begin.

Preflow Application:

Preflow is used to purge the imme-

diate weld area of atmosphere.

Preflow also aids in consistent arc

starting. Preflow is preset and is not

adjustable.

Post Flow Application:

Postflow is required to cool tung-

sten and weld, and to prevent con-

tamination of tungsten and weld. In-

crease postflow time if tungsten or

weld are dark in appearance (see

Section 3-8).

5

6

7

Tools Needed:

5/8, 1-1/8 in

4

1

3

2

Loading...

Loading...