ENGLISH

OM-225 389 Page 5

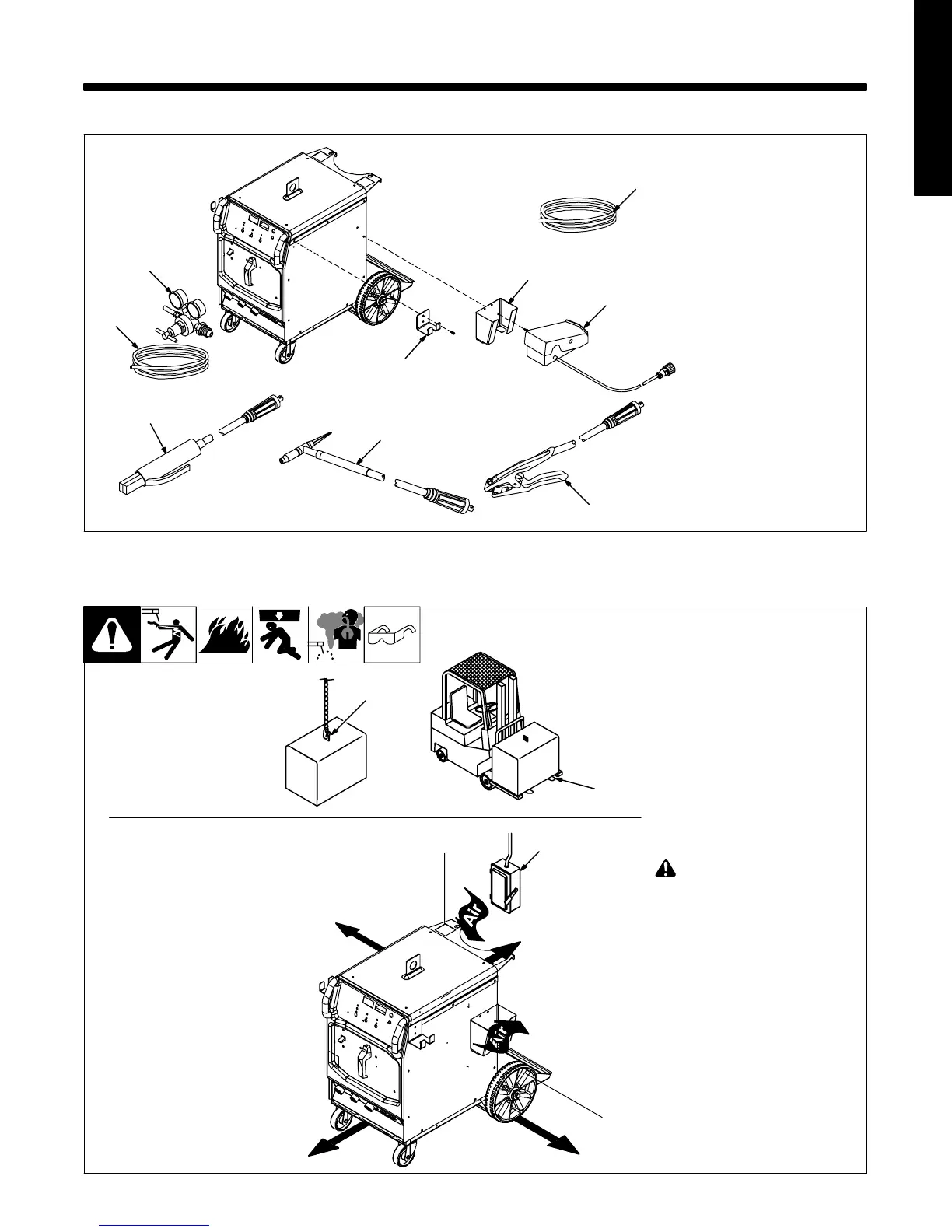

SECTION 2 − INSTALLATION

2-1. Included with Your Unit

1 12 ft (3.7 m) Work Cable

With Clamp And

Quick-Connect

2 WP1712SFDI 150 Amp

TIG Torch with 12 ft (3.7 m)

Cable And Quick-Connect

3 Electrode Holder and

Quick-Connect

4 Gas Hose

5 Gas Regulator

6 Cable/Torch Hanger

7 Foot Pedal Holder

8 8 ft (2.4 m) Primary Cord

Without Plug (208/230

Models Only)

9 RFCS-14 Foot Control with

20 ft (6 m) Cable

. Some assembly is required.

For options and accessories see

back of book or contact your dis-

tributor.

1

2

3

4

5

8

9

804 464-B

6

7

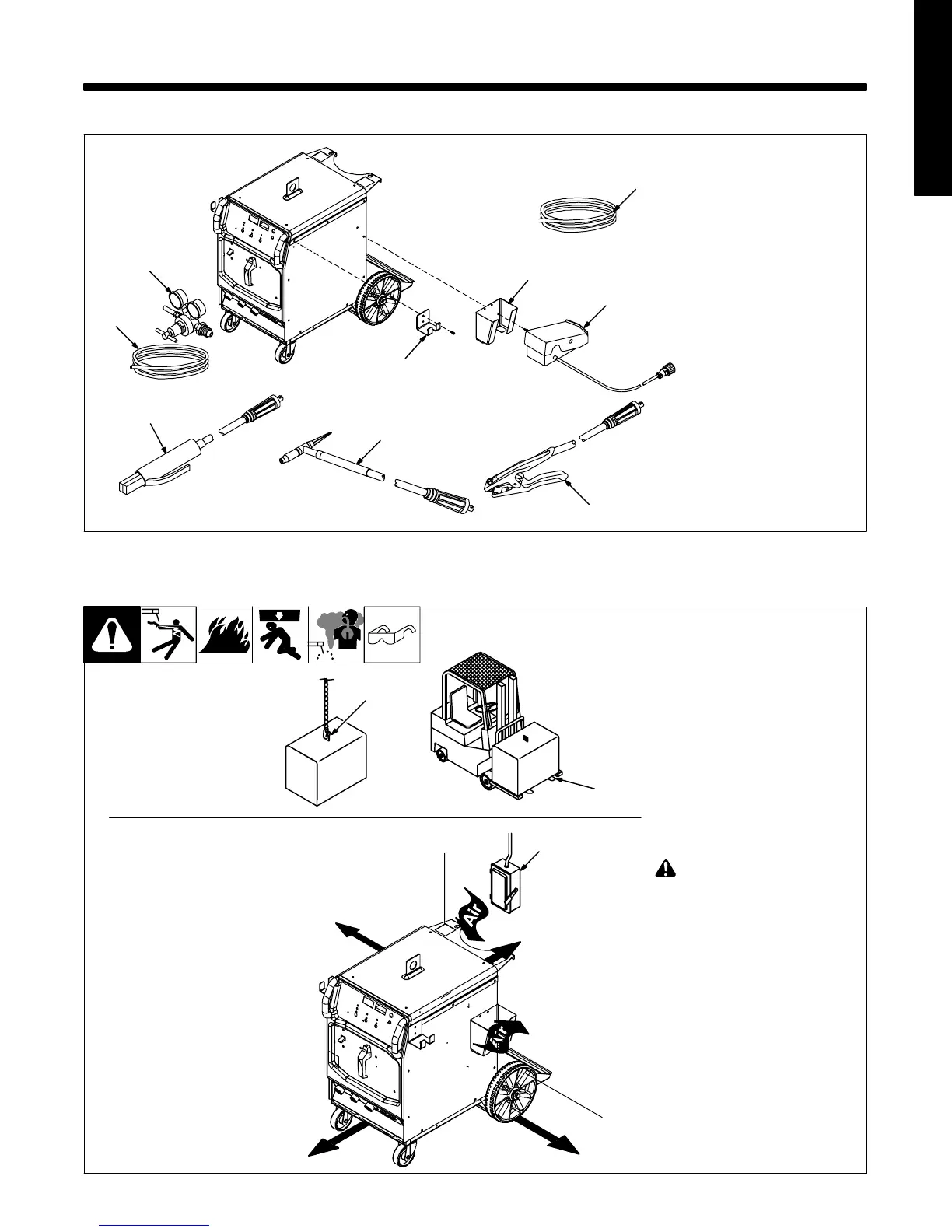

2-2. Selecting A Location

1 Lifting Eye

2 Lifting Forks

Use lifting eye or lifting forks to

move unit.

If using lifting forks, extend forks

beyond opposite side of unit.

3 Line Disconnect Device

Locate unit near correct input pow-

er supply.

Position unit so air can circulate.

For information about sources of

high-frequency see Section 6.

For carts and caster kits see back

of book or contact your distributor.

! Special installation may be

required where gasoline or

volatile liquids are present −

see NEC Article 511 or CEC

Section 20.

1

2

Movement

3

18 in.

(460 mm)

Location And Airflow

OR

18 in. (460 mm)

18 in. (460 mm)18 in. (460 mm)

Loading...

Loading...