ENGLISH

OM-225 389 Page 39

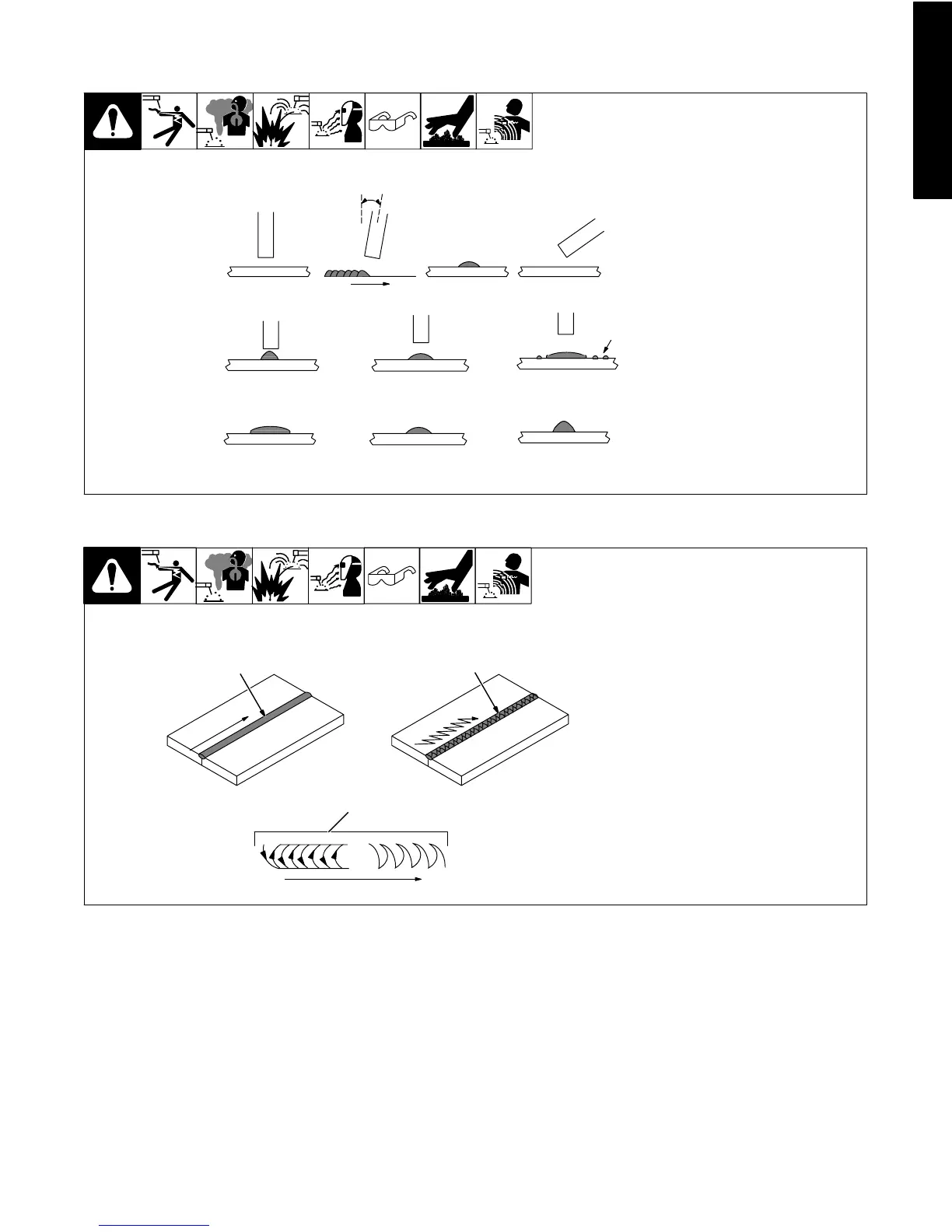

9-7. Conditions That Affect Weld Bead Shape

S-0061

Slow

Normal Fast

10° - 30°

Drag

Too Short

Normal Too Long

Spatter

Angle Too Small

Angle Too Large

Correct Angle

Electrode Angle

Arc Length

Travel Speed

. Weld bead shape is affected

by electrode angle, arc

length, travel speed, and

thickness of base metal.

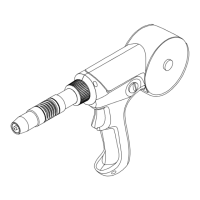

9-8. Electrode Movement During Welding

S-0054-A

. Normally, a single stringer

bead is satisfactory for most

narrow groove weld joints;

however, for wide groove weld

joints or bridging across gaps,

a weave bead or multiple

stringer beads work better.

1 Stringer Bead − Steady

Movement Along Seam

2 Weave Bead − Side to Side

Movement Along Seam

3 Weave Patterns

Use weave patterns to cover a

wide area in one pass of the elec-

trode. Do not let weave width ex-

ceed 2-1/2 times diameter of

electrode.

1

2

3

Loading...

Loading...