ENGLISH

OM-225 389 Page 25

SECTION 4 − MAINTENANCE AND TROUBLESHOOTING

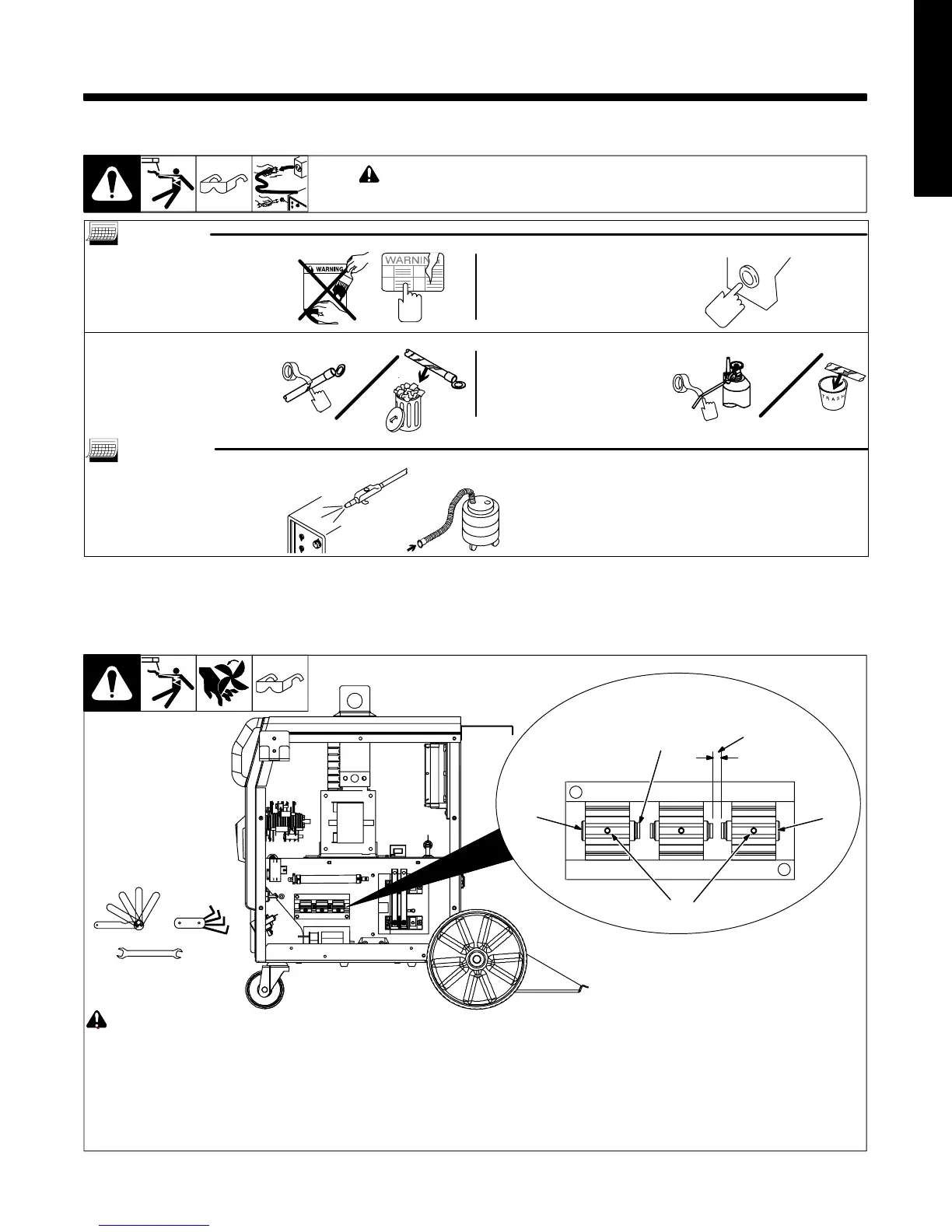

4-1. Routine Maintenance

! Disconnect power before maintaining.

. Maintain more often during severe conditions.

3 Months

Replace unreadable labels.

Replace o-ring in Electrode/Gas

Output receptacle if cracked.

Repair or replace cracked weld

cable.

Repair or replace cracked gas

hose.

6 Months

Blow out or vacuum inside.

Or

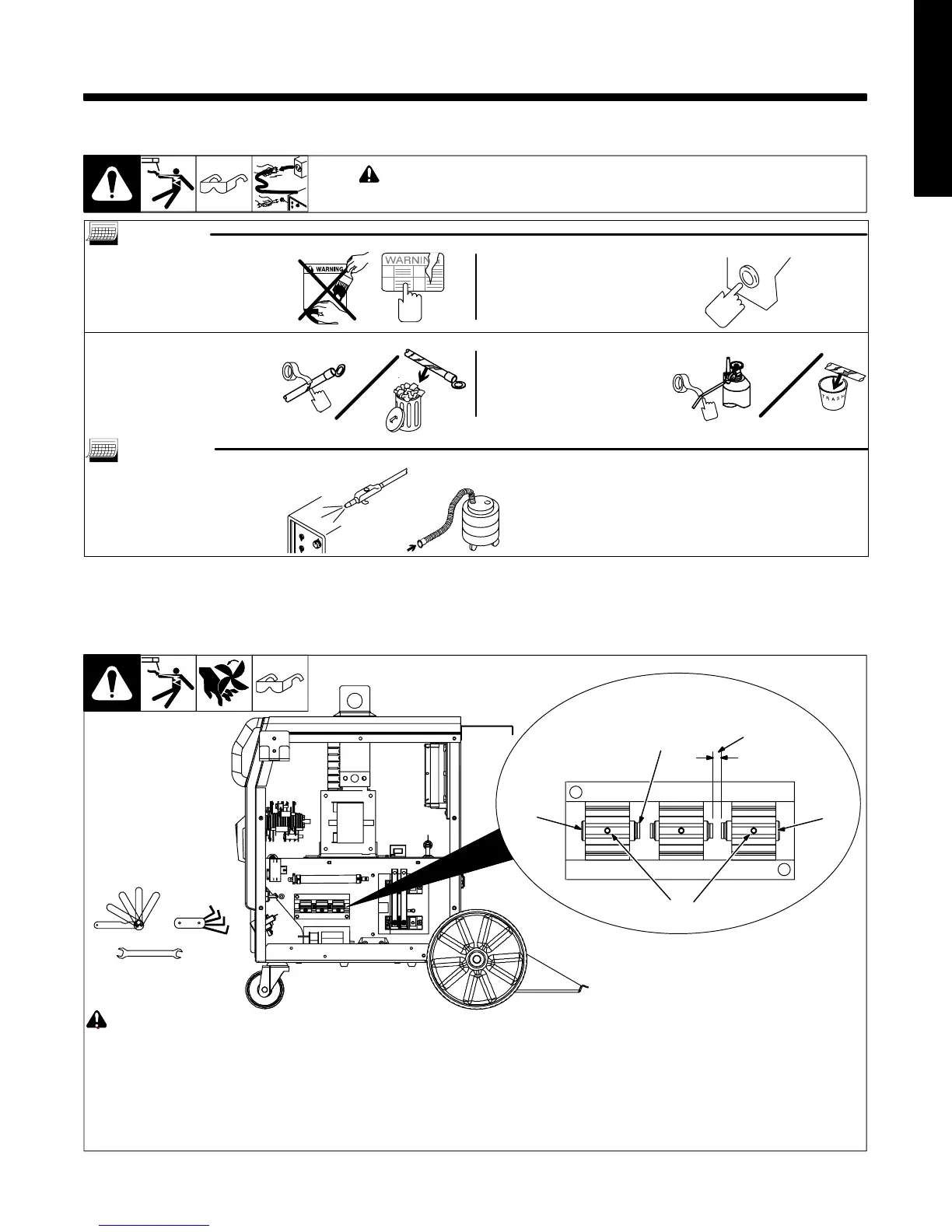

4-2. Adjusting Spark Gaps

! Disconnect and lockout/tagout in-

put power before adjusting spark

gaps.

Remove right side panel.

1 Tungsten End Of Point

Replace point if tungsten end disappears;

do not clean or dress tungsten.

2 Spark Gap

Normal spark gap is 0.008 in. (0.203 mm).

If adjustment is needed, proceed as fol-

lows:

3 Adjustment Screws

Loosen screws. Place gauge of proper

thickness in spark gap.

4 Pressure Point

Apply slight pressure at point until gauge is

held firmly in gap. Tighten screws to 12 in/

lbs torque. Adjust other gap.

Reinstall right side panel.

Tools Needed:

804 236-C /Ref. 803 592-C

1

2

4

3

3/8 in

4

Loading...

Loading...