OM-225 389 Page 16

3-2. Ammeter, Voltmeter And Parameter Display

1 Ammeter

Displays actual amperage while

welding. Meter also displays preset

parameters for any of the following

units of measure when they are ac-

tive: amperage, time, percentage or

frequency.

2 Voltmeter

Displays output or open-circuit volt-

age while output is on. Meter also

displays preset parameters.

1

2

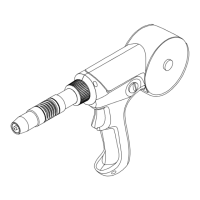

3-3. Amperage/Purge Control

1 Main Amps Push Button

(Amperage Control)

2 Encoder Adjustment Control

3 Ammeter

See Section 3-7 for Amperage

range.

Amperage Control:

Press and release Main Amps push

button, and turn Encoder control to

set weld amperage. Weld amper-

age setting is also peak amperage

when Pulser function is active (see

Section 3-5).

Purge Control:

Press and hold Main Amps push

button to activate the gas purge.

Purge time can be adjusted from 1

to 50 seconds by turning Encoder

control while holding the Amps but-

ton. Preset purge time is 0 seconds.

2

200 A

1

3

3-4. Process Control

1

1 Process Control

Press Process button until desired

process LED is illuminated:

TIG - When selected, an HF (non-

contact) arc starting method is acti-

vated. Weld output is not available

until a remote control is activated.

This method can be used with either

AC or DC TIG welding. Make con-

nections according to Section 2-13.

! Weld output terminals are en-

ergized when power is on, and

Output On LED is lit.

Stick (SMAW) - When Stick is se-

lected, weld output is on, terminals

are energized, and output LED is lit.

This method can be used with either

AC or DC Stick welding. Make con-

nections according to Section 2-14.

Loading...

Loading...