OM-225 389 Page 36

SECTION 9 − STICK WELDING (SMAW) GUIDELINES

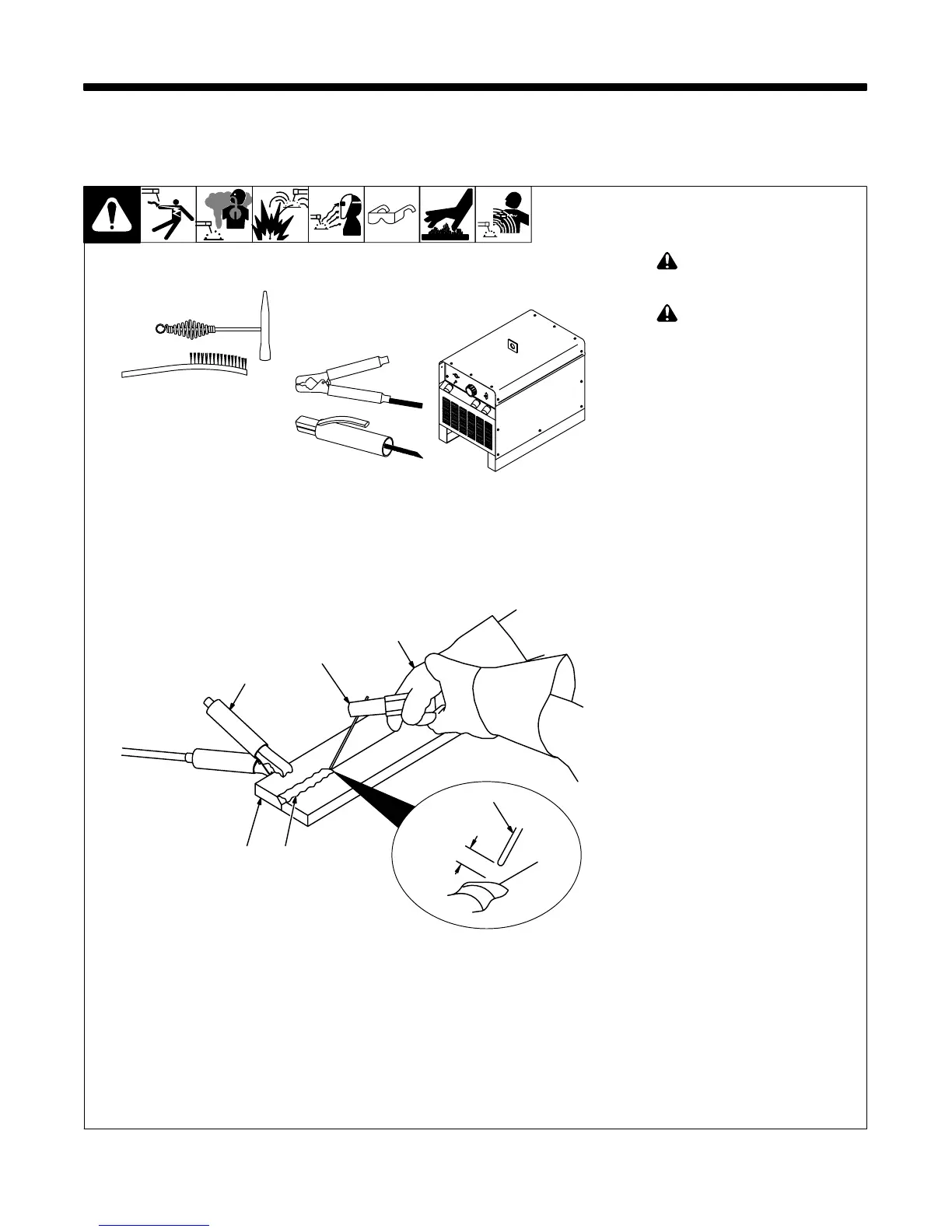

9-1. Stick Welding Procedure

stick 2008−05 − ST-151 593

! Weld current starts when

electrode touches work-

piece.

! Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp

as close to the weld as

possible.

. Always wear appropriate per-

sonal protective clothing.

1 Workpiece

Make sure workpiece is clean be-

fore welding.

2 Work Clamp

3 Electrode

A small diameter electrode re-

quires less current than a large

one. Follow electrode manufactur-

er’s instructions when setting weld

amperage (see Section 9-2).

4 Insulated Electrode Holder

5 Electrode Holder Position

6 Arc Length

Arc length is the distance from the

electrode to the workpiece. A short

arc with correct amperage will give

a sharp, crackling sound.

7 Slag

Use a chipping hammer and wire

brush to remove slag. Remove

slag and check weld bead before

making another weld pass.

1

4

3

5

2

7

6

Tools Needed:

Equipment Needed:

Constant Current

Welding Power Source

Loading...

Loading...